Opel Frontera UBS. Manual - part 983

4A1–15

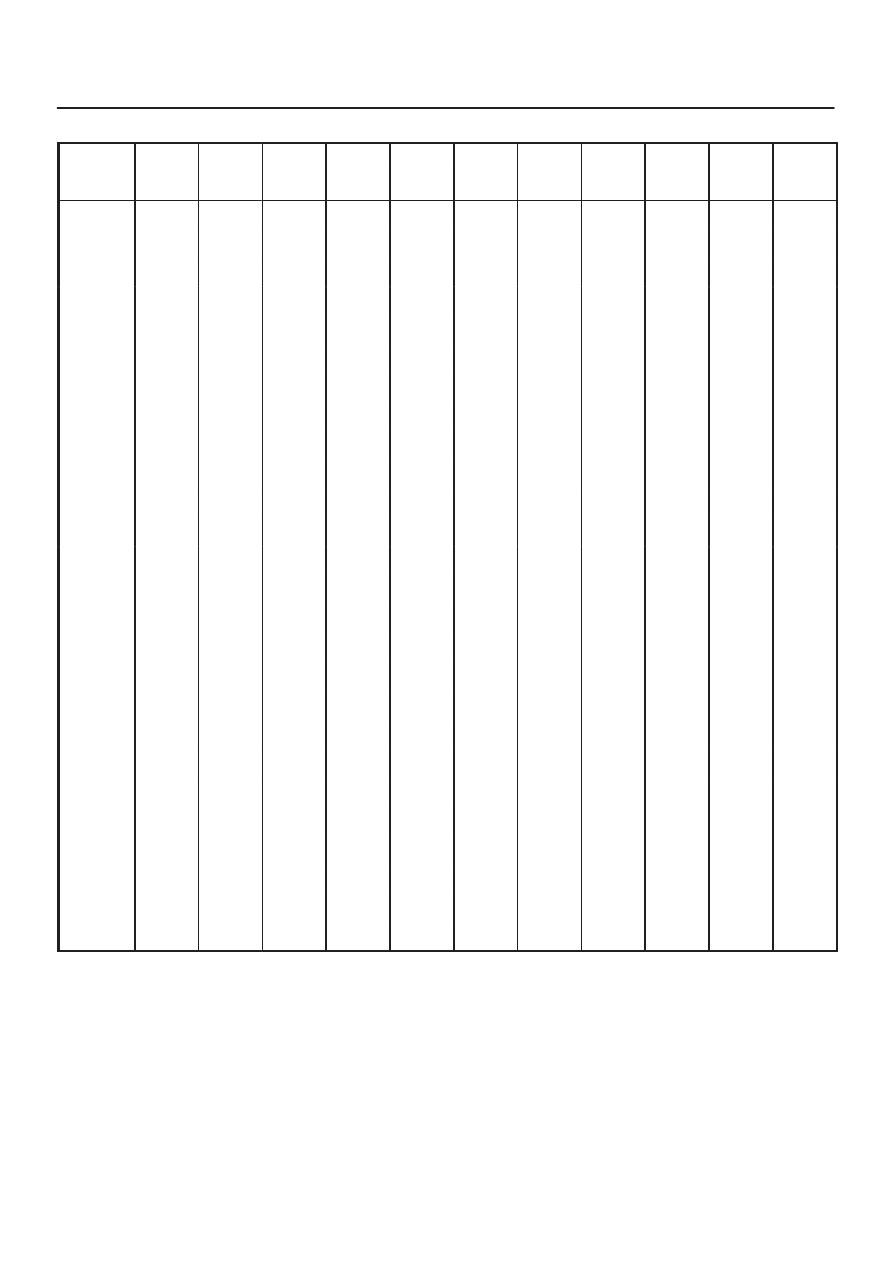

DIFFERENTIAL (FRONT)

8. Select the shim using the chart;

Pinion marking

+10

+8

+6

+4

+2

0

–2

–4

–6

–8

–10

Dial indicator

reading

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

mm

(Inches)

0.081

2.18

(0.0858)

0.082

2.18

(0.0858)

2.20

(0.0866)

0.083

2.18

(0.0858)

2.20

(0.0866)

2.23

(0.0882)

0.084

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

0.085

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

0.086

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

0.087

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

0.088

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

0.089

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

0.090

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

0.091

2.18

(0.0858)

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

0.092

2.20

(0.0866)

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

0.093

2.24

(0.0882)

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

0.094

2.26

(0.0890)

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

0.095

2.28

(0.0898)

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

0.096

2.32

(0.0914)

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.097

2.34

(0.0921)

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.098

2.36

(0.0929)

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.099

2.38

(0.0937)

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0

2.42

(0.0953)

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.001

2.44

(0.0961)

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.002

2.46

(0.0969)

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.003

2.48

(0.0977)

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.004

2.52

(0.0992)

2.54

(0.1000)

2.56

(0.1008)

0.005

2.54

(0.1000)

2.56

(0.1008)

0.006

2.56

(0.1008)

NOTE: When ordering shims, find the part number in the

parts catalog by using the thickness of shims listed in the

above table.

4. Place the shim on the drive pinion, with the chamfered

side turned towards the pinion head then install the

inner bearing onto the pinion using an installer

9–8522–1165–0 and a press.