Opel Frontera UBS. Manual - part 943

00 – 10 SERVICE INFORMATION

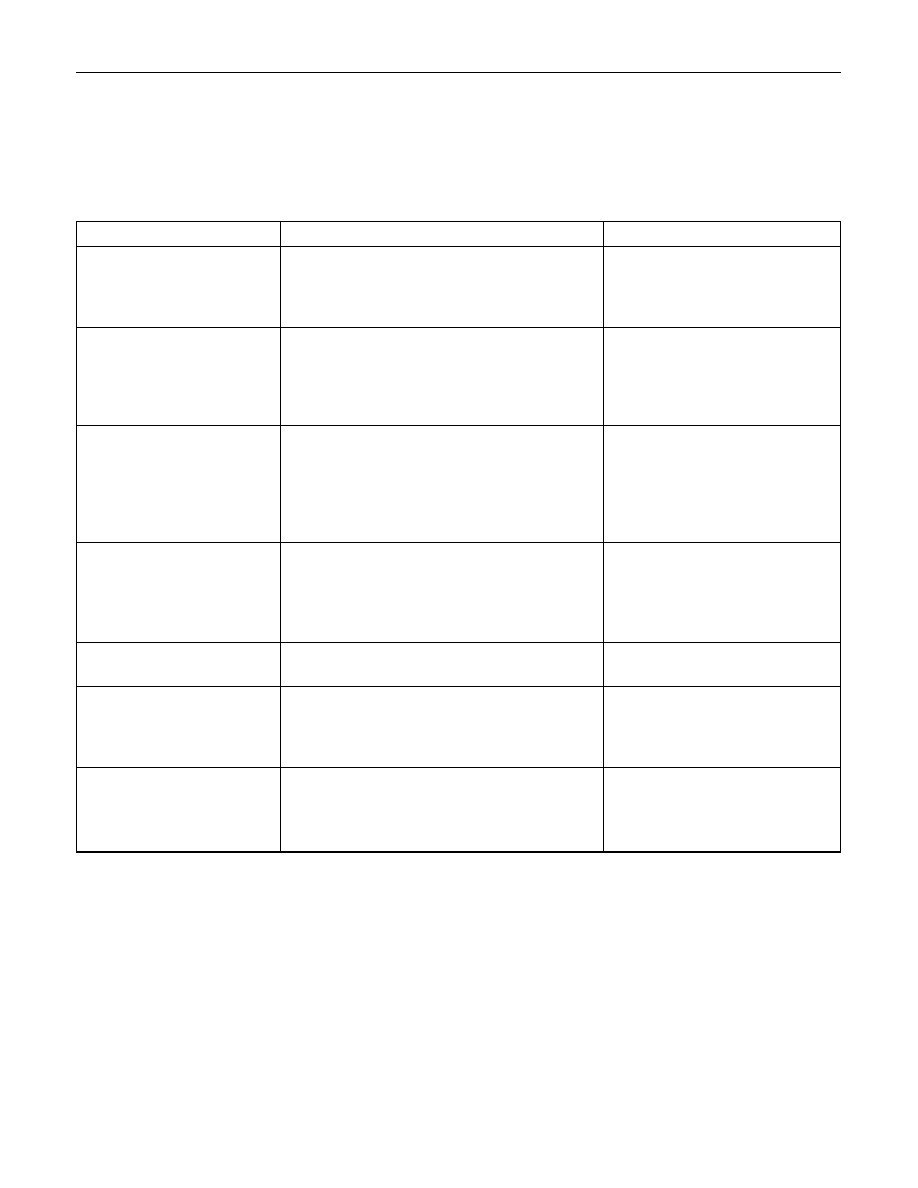

Problem

Possible Cause

Correction

STEERING COLUMN (CONT.)

TURN SIGNAL SWITCH

This troubleshooting covers mechanical problems only. See Section 8 for turn signal switch electrical

diagnosis.

Turn Signal Will Not Stay

in Turn Position

Turn Signal Will Not

Cancel

Turn Signal Difficult to

Operate

Turn Signal Will Not

Indicate Lane Change

Hezard Switch Cannot Be

Turned Off

No Turn Signal Lights

Front or Rear Turn Signal

Lights Not Flashing

1. Foreign material or loose parts

preventing movement of yoke.

2. Broken or missing detent or canceling

spring.

1. Loose switch mounting screws.

2. Switch or anchor bosses broken.

3. Broken, missing or out of position

detent, return or canceling spring.

4. Worn canceling cam.

1. Turn signal switch arm loose.

2. Yoke broken or distorted.

3. Loose or misplaced springs.

4. Foreign parts and/or material.

5. Loose turn signal switch mounting

screws.

1. Broken lane change pressure pad or

spring hanger.

2. Broken, missing or misplaced lane

change spring.

3. Base of wire damaged.

1. Foreign material between hazard

switch to turn signal switch body.

1. Electrical failure in chassis harness.

2. Inoperative turn signal flasher unit.

3. Loose chassis harness connector.

1. Burned-out damaged turn signal bulb.

2. High resistance connection to ground

at bulb socket.

3. Loose chassis harness connector.

Repair or replace signal switch.

Replace signal switch.

Tighten mounting screws.

Replace turn signal switch.

Replace turn signal switch.

Replace turn signal switch.

Tighten arm screw.

Replace turn signal switch.

Replace turn signal switch.

Repair turn signal switch.

Tighten mounting screws.

Replace turn signal switch.

Replace turn signal switch.

Replace turn signal switch.

Repair or replace hazard

switch.

Refer to Section 8 “Electrical

Troubleshooting”.

Replace flasher unit.

Repair loose connector.

Replace bulb.

Repair bulb socket.

Repair loose connector.