Opel Frontera UBS. Manual - part 942

00 – 6 SERVICE INFORMATION

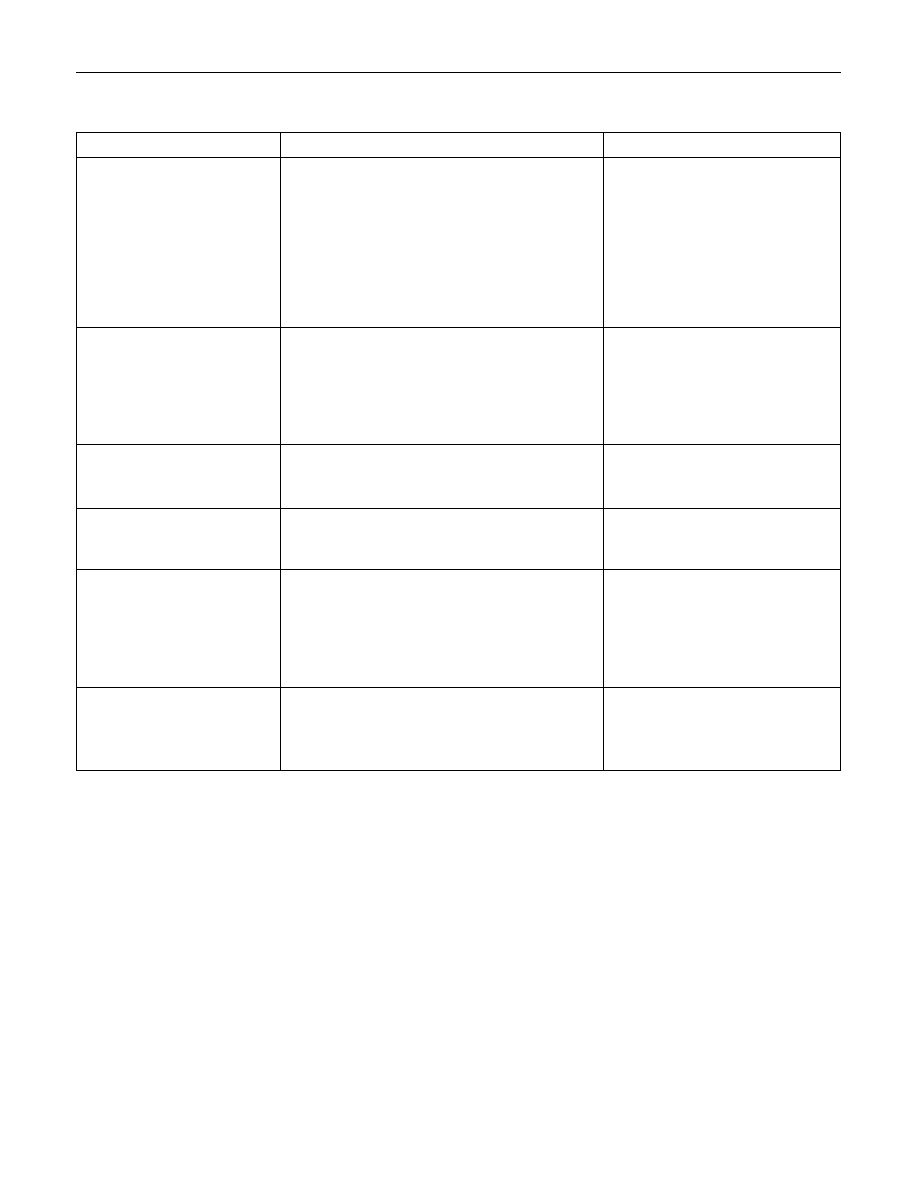

Problem

Possible Cause

Correction

GENERAL TROUBLESHOOTING (CONT.)

Wandering or Poor

Steering Stability

Erratic Steering When

Bracking

Low or Uneven Trim

Height

Suspension Bottoms

Body Leans

Cupped Tires

1. Mismatched or unevenly worn tires.

2. Loose steering linkage ball joints.

3. Faulty shock absorbers.

4. Loose stabilizer bar.

5. Broken or sagging springs.

6. Steering gear misadjustment.

7. Improper wheel alignment.

1. Worn wheel bearings.

2. Broken or sagging springs.

3. Leaking caliper.

4. Warped discs.

5. Badly worn brake pads.

6. Tires are inflated unequally.

1. Broken or sagging springs.

2. Vehicle overloaded.

3. Incorrect springs.

1. Vehicle overloaded.

2. Faulty shock absorber.

3. Incorrect, broken or sagging springs.

1. Loose stabilizer bar.

2. Faulty shock absorbers, struts or

mounting.

3. Broken or sagging springs.

4. Vehicle overloaded.

1. Worn wheel bearings.

2. Excessive tire or wheel runout.

3. Worn ball joints.

4. Tire out of balance.

Replace tire or inflate tires to

proper pressure.

Replace ball joints.

Replace shock absorber.

Tighten or replace stabilizer bar

or bushings.

Replace spring (pairs).

Check or adjust steering gear.

Adjust wheel alignment.

Replace wheel bearings.

Replace spring (pairs).

Repair or replace caliper.

Replace brake disc.

Replace brake pads.

Inflate tires to proper pressure.

Replace springs (In pairs)

Reduce load.

Adjust or replace torsion bar.

Reduce load.

Replace shock absorber.

Replace springs.

Tighten stabilizer bar bolts or

replace bushings.

Replace shock absorber.

Replace springs (In pairs)

Reduce load.

Replace wheel bearings.

Replace tire or wheel.

Replace ball joints.

Adjust tire balance.