Opel Frontera UBS. Manual - part 934

1B–130 AIR CONDITIONING

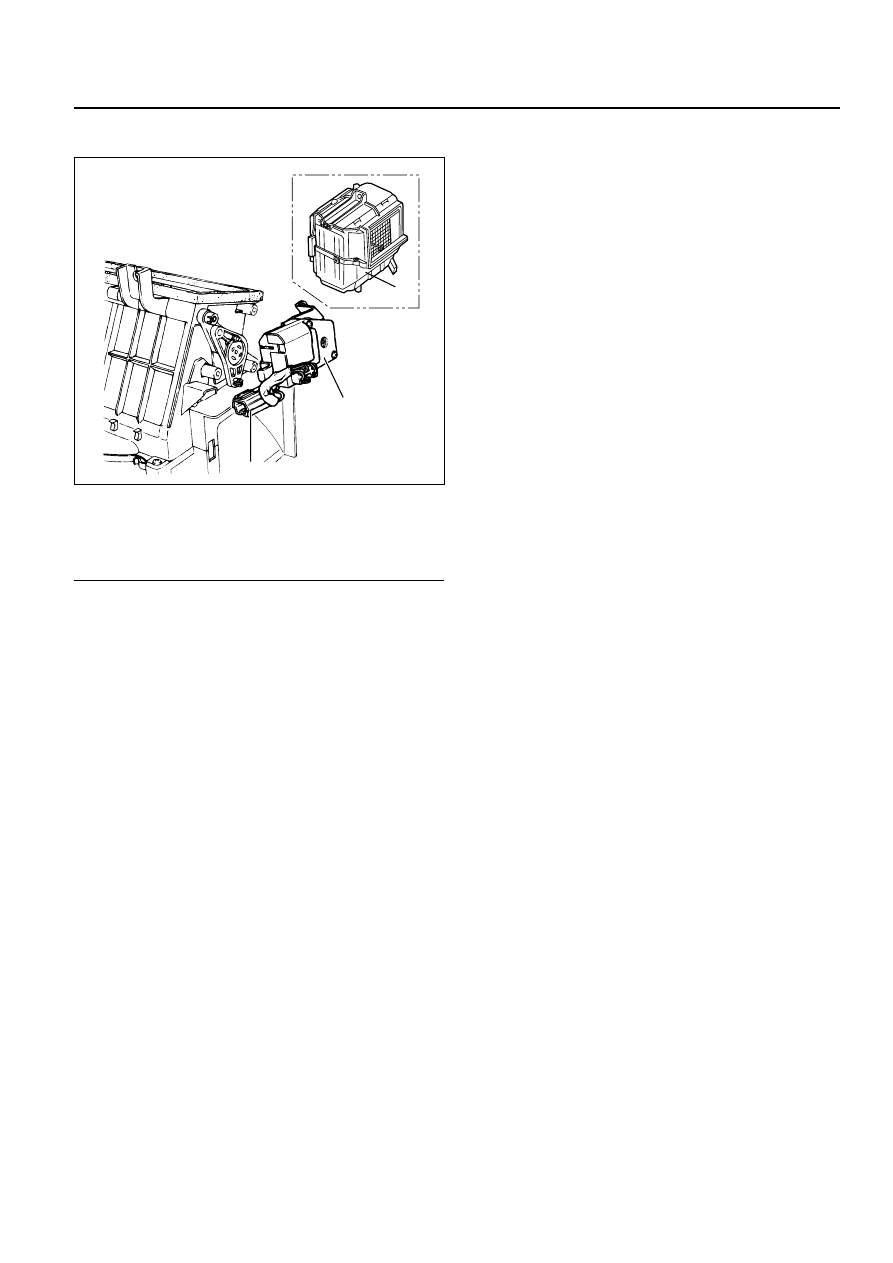

Intake Actuator

Legend

(1)

Evaporator Assembly

(2)

Intake Actuator

(3)

Intake Actuator Connector

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

•

Refer to Refrigerant Recovery in this section.

3. Remove the evaporator assembly.

•

Refer to Eevaporator Assembly section.

4. Disconnect the intake actuator connector.

5. Remove the intake actuator.

Installation

To install, follow the removal step in the reverse

order.

1

2

3

860RX018

This illustration is based on RHD