Opel Frontera UBS. Manual - part 644

8D–6

WIRING SYSTEM

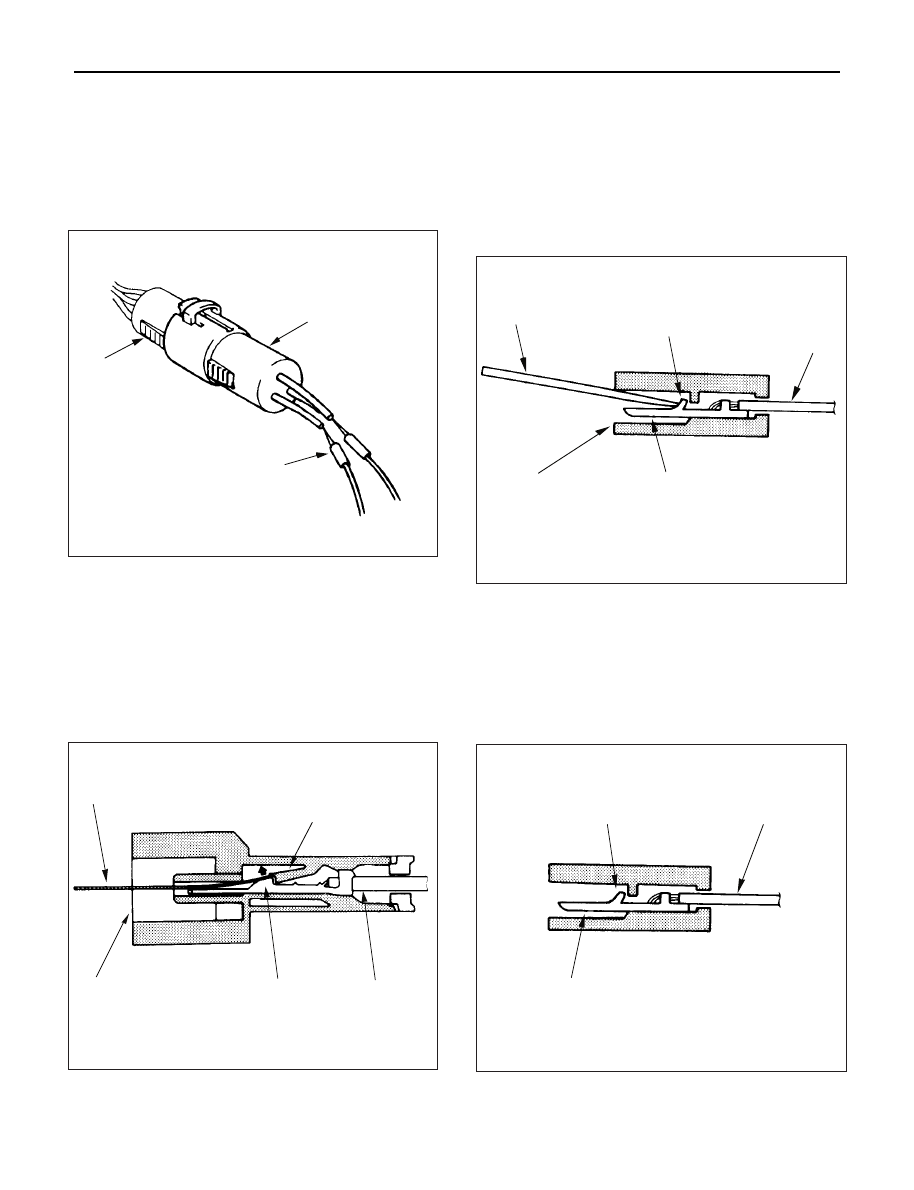

Waterproof Connector Inspection

It is not possible to insert the test probes (2) into the

connector wire side of a waterproof connector.

Use one side of a connector (1) with its wires cut to make

the test. Connect the test connector to the connector to

be tested (3). Connect the test probes to the cut wires to

check the connector continuity.

Connector Pin Removal – Connector

Housing Tang Lock Type

1. Insert a slender shaft (1) into the connector housing

open end (5).

2. Push the tang lock (2) up (in the direction of the arrow

in the illustration).

Pull the wire (3) with pin (4) free from the wire side of

the connector.

Connector Pin Removal – Pin Tang Lock

Type

1. Insert a slender shaft (1) into the connector housing

open end (5).

2. Push the tang lock (2) flat (toward the wire (3) side of

the connector.

Pull the wire with pin (4) free from the wire side of the

connector.

Connector Pin Insertion

1. Check that the tang lock (1) is fully up.

2. Insert the pin (3) from the connector wire (2) side.

Push the pin in until the tang lock closes firmly.

3. Gently pull on the wires to make sure that the

connector pin is firmly set in place.

1

3

2

1

2

3

5

4

1

2

3

4

5

1

2

3