Opel Frontera UBS. Manual - part 626

7C–18

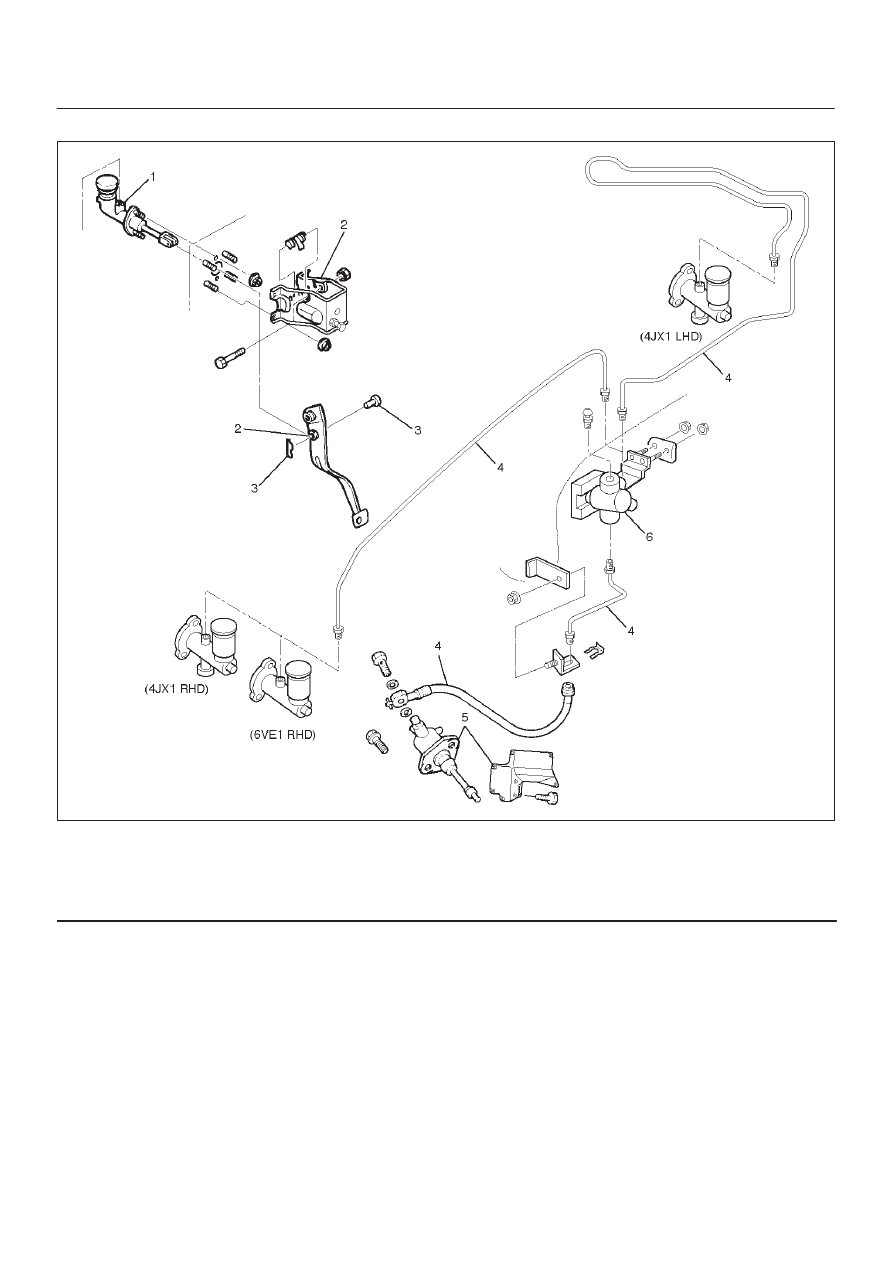

CLUTCH

(Except 6VE1 LHD)

203RW009

Legend

(1) Master Cylinder Assembly

(2) Pedal Assembly

(3) Pin and Joint Pin

(4) Oil Line Pipe

(5) Slave Cylinder Assembly and Heat Protector

(6) Damper Cylinder Assembly

Removal

1. Remove pin and jaw joint pin.

2. Remove pedal assembly.

3. Remove oil line pipe.

4. Remove slave cylinder assembly and heat protector.

5. Remove master cylinder assembly.

6. Remove damper cylinder assembly (except V6 LHD).

Inspection and Repair

Make necessary adjustments, repairs, and part

replacement if wear, damage or other problems are

discovered during inspection.