Opel Frontera UBS. Manual - part 523

6E–222

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

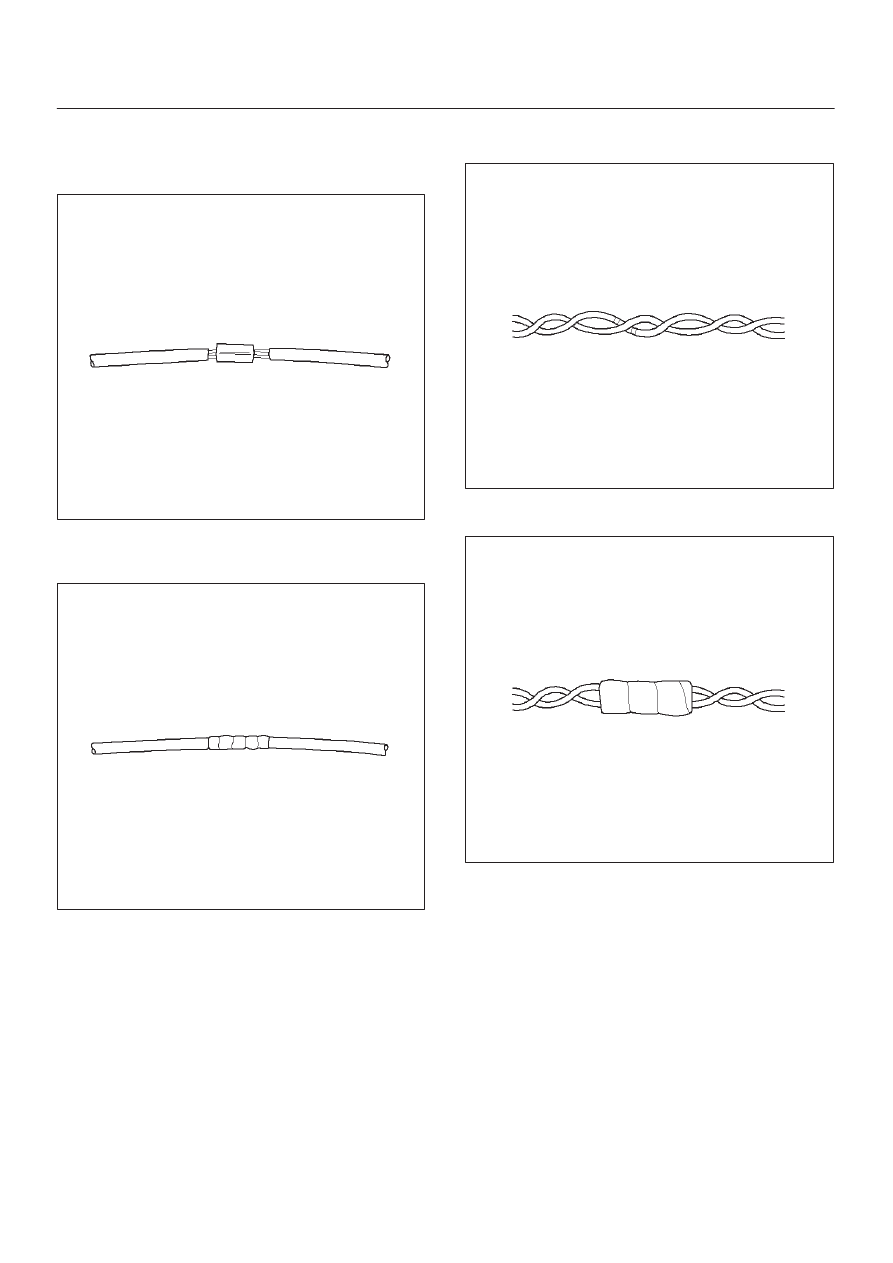

1. Use splice clips and rosin core solder in order to splice

the two wires together.

052

2. Cover the splice with tape in order to insulate it from

the other wires.

053

3. Twist the wires as they were before starting this

procedure.

054

4. Tape the wires with electrical tape. Hold in place.

055