Opel Frontera UBS. Manual - part 390

ENGINE MECHANICAL 6A – 33

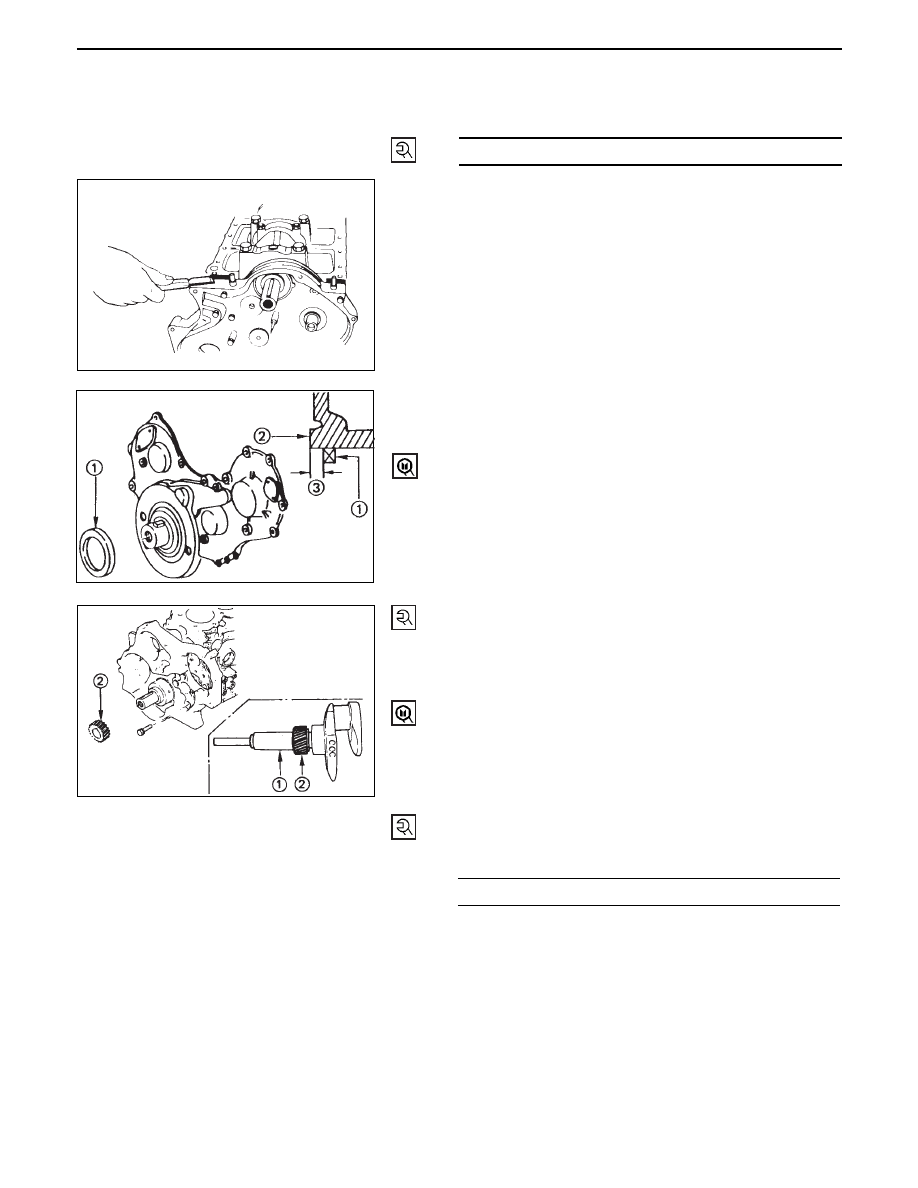

2) Tighten the timing gear case bolt together with

the timing gear case gasket to the specified

torque.

19 (1.9/14)

N·m(kg·m/lb·ft)

3) Cut away the gasket protruding above the fitting

surfaces (as shown in the illustration).

4.

Crankshaft Front Oil Seal

•

Use the installer to install the front oil seal 1 to

the gear case cover 2.

Oil Seal Installer: 5-8840-2061-0

Note the oil seal installation depth 3 shown in

the illustration.

Depth 3 = 1 mm (0.0394 in.)

3.

Crankshaft Timing Gear

Use the crankshaft timing gear installer 1 to install the

timing gear 2.

The crankshaft timing mark (“X – X”) must be facing

outward.

Crankshaft Timing Gear Installer: 5-8522-0024-0

2.

Camshaft Timing Gear

•

Tighten the fixing bolt to the specified torque.

64 (6.5/47)

N·m(kg·m/lb·ft)

1.

Cylinder Head

•

Refer to “Cylinder head” in Section 6A2.