Opel Frontera UBS. Manual - part 290

6E–66

ENGINE DRIVEABILITY AND EMISSIONS

D

Poor connection at PCM. Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damage terminals,

and a poor terminal-to-wire connection.

D

Damaged harness. Inspect the wiring harness for

damage. If the harness is not damaged, observe an

affected sensor’s displayed value on the Tech 2 with

the ignition “ON” and the engine “OFF” while you move

the connectors and the wiring harnesses related to the

following sensors:

D

IAT

D

ECT

D

TP

D

MAP

D

EGR

D

TFT

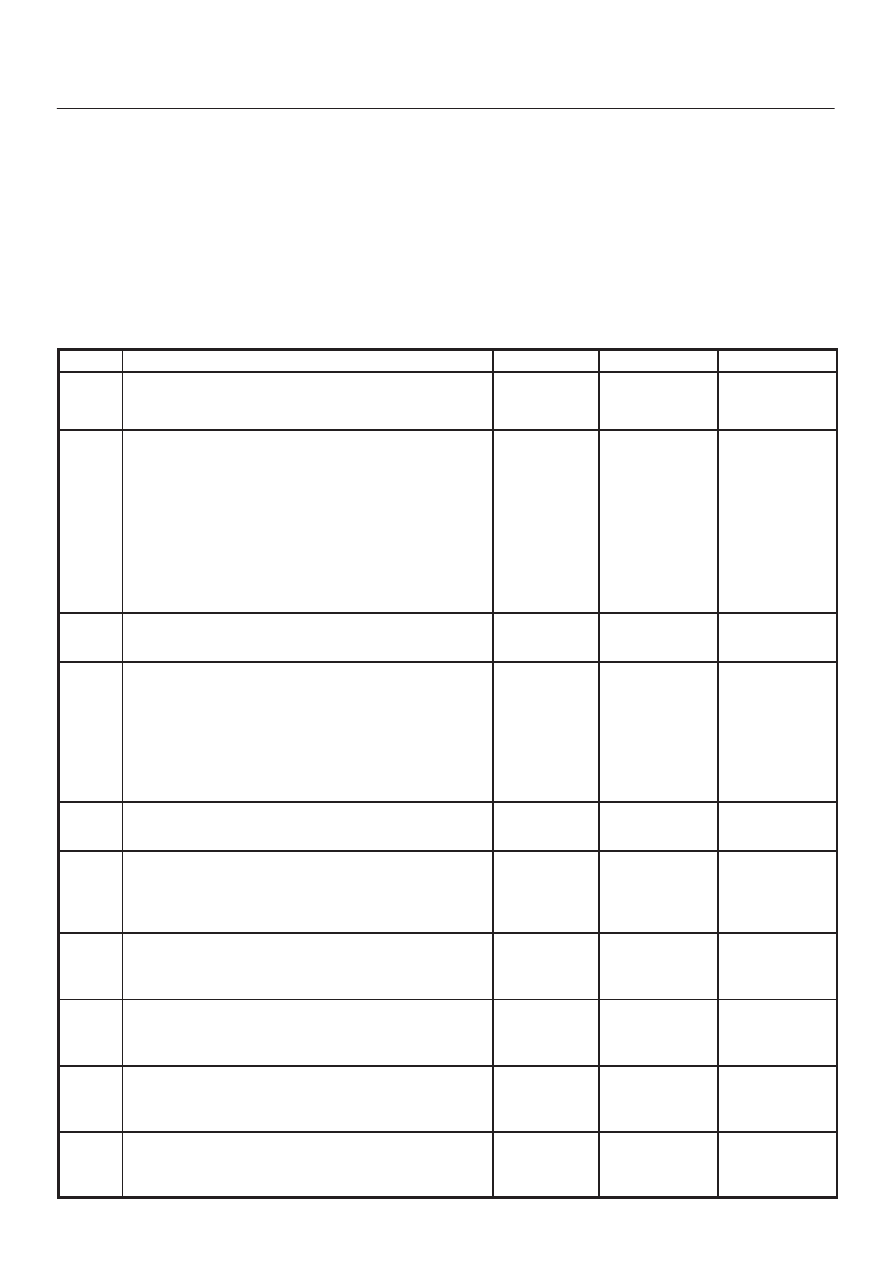

Multiple PCM Information Sensor DTCs Set

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Turn the ignition “OFF,” disconnect the PCM.

2. Turn the ignition “ON,” check the 5 volt reference A

circuit for the following conditions:

D

A poor connection at the PCM.

D

An open between the PCM connector and the

splice.

D

A short to ground.

D

A short to voltage.

Is there an open or short?

—

Go to

Step 3

Go to

Step 4

3

Repair the open or short.

Is the action complete?

—

Verify repair

—

4

Check the sensor ground circuit for the following

conditions:

D

A poor connection at the PCM or the affected

sensors.

D

An open between the PCM connector and the

affected sensors.

Is there an open or a poor connection?

—

Go to

Step 5

Go to

Step 6

5

Repair the open or the poor connection.

Is the action complete?

—

Verify repair

—

6

Measure the voltage between the EGR pintle position

sensor signal circuit at the PCM harness connector and

ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 7

Go to

Step 12

7

Measure the voltage between the MAP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 8

Go to

Step 15

8

Measure the voltage between the TP sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 9

Go to

Step 16

9

Measure the voltage between the IAT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 10

Go to

Step 17

10

Measure the voltage between the ECT sensor signal

circuit at the PCM harness connector and ground.

Does the voltage measure near the specified value?

0 V

Go to

Step 11

Go to

Step 18