Opel Frontera UBS. Manual - part 288

6E–58

ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

(Cont'd)

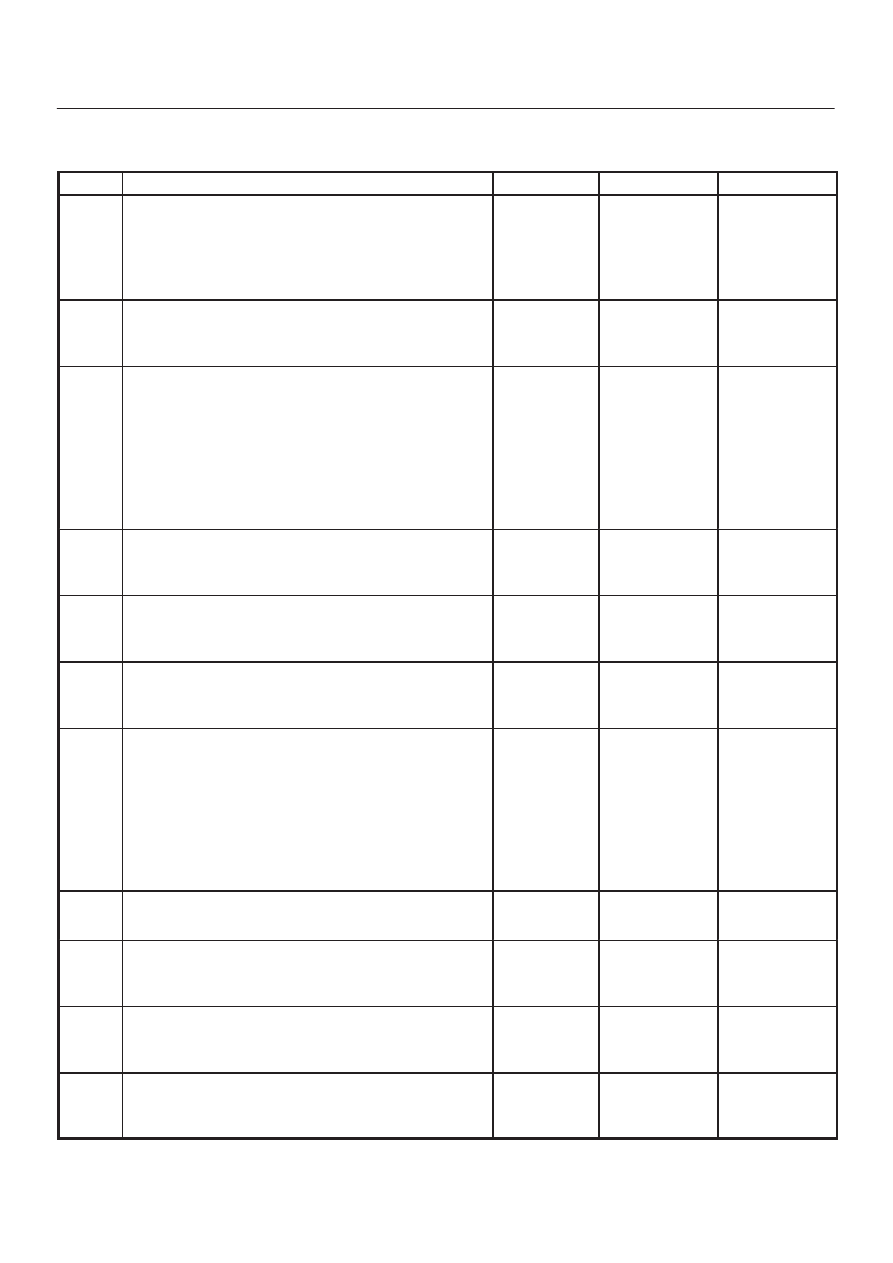

Step

No

Yes

Value(s)

Action

34

1. Remove the A/C compressor relay.

2. Ignition “ON.”

3. Use a DVM to check voltage at both of the BRN

wires at the A/C compressor relay socket.

Is the voltage equal to the specified value?

+B

Go to

Step 36

Go to

Step 35

35

Repair the faulty BRN wire between the A/C fuse and

the A/C compressor relay .

Is the action complete?

—

Verify repair

—

36

1. A/C compressor relay removed.

2. Engine idling.

3. A/C “ON.”

4. Blower “ON.”

5. Use a DVM to measure voltage between the

GRN/BLK wire at the A/C compressor relay socket

and battery

±

.

Did the DVM indicate the specified value?

+B

Go to

Step 40

Go to

Step 37

37

Check for an open GRN/BLK wire between PCM

terminal B-14 and the A/C compressor relay.

Was the wire open?

—

Go to

Step 38

Go to

Step 39

38

Repair the open GRN/BLK wire between the PCM and

the A/C compressor relay.

Is the action complete?

—

Verify repair

—

39

Check for a damaged pin or terminal at B-14 of the

PCM.

Was a damaged pin or a terminal found?

—

Go to

Step 32

Go to

Step 33

40

1. A/C compressor relay removed.

2. Connect a fused jumper at the A/C compressor

relay socket between either BRN wire and the

BRN/YEL wire.

3. Engine idling.

4. A/C “ON.”

5. Blower “ON.”

Did the compressor magnetic clutch engage?

—

Go to

Step 41

Go to

Step 42

41

Repair the A/C compressor relay.

Is the action complete?

—

Verify repair

—

42

Check for an open circuit between the A/C compressor

relay and the A/C clutch.

Was an open circuit found?

—

Go to

Step 43

Go to

Step 44

43

Repair the open circuit between the compressor Clutch

and the A/C compressor relay.

Is the action complete?

—

Verify repair

—

44

Service the compressor clutch or replace the

compressor due to a faulty internal overheat switch.

Is the action complete?

—

Verify repair

—