Content .. 2345 2346 2347 2348 ..

Opel Frontera UBS. Manual - part 2347

6E–424

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

Mass Air Flow, TP sensor 1, TP sensor 2 display on the

Tech 2 while moving connectors and wiring harnesses

related to the sensor.

D

Plugged intake air duct or filter element

D

A wide - open throttle acceleration from a stop should

cause the mass air flow displayed on a Tech 2 to

increase from about 3 – 7 g/s at idle to 100 g/s or

greater at the time of the 1 – 2 shift. If not, check for a

restriction.

A change in the display will indicate the location of

the fault. If DTC P1514 cannot be duplicated, the

information included in the Faillure Records data can

be useful in determined vehicle mileage since the

DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1514 Diagnostic Chart may

isolate the cause of the fault.

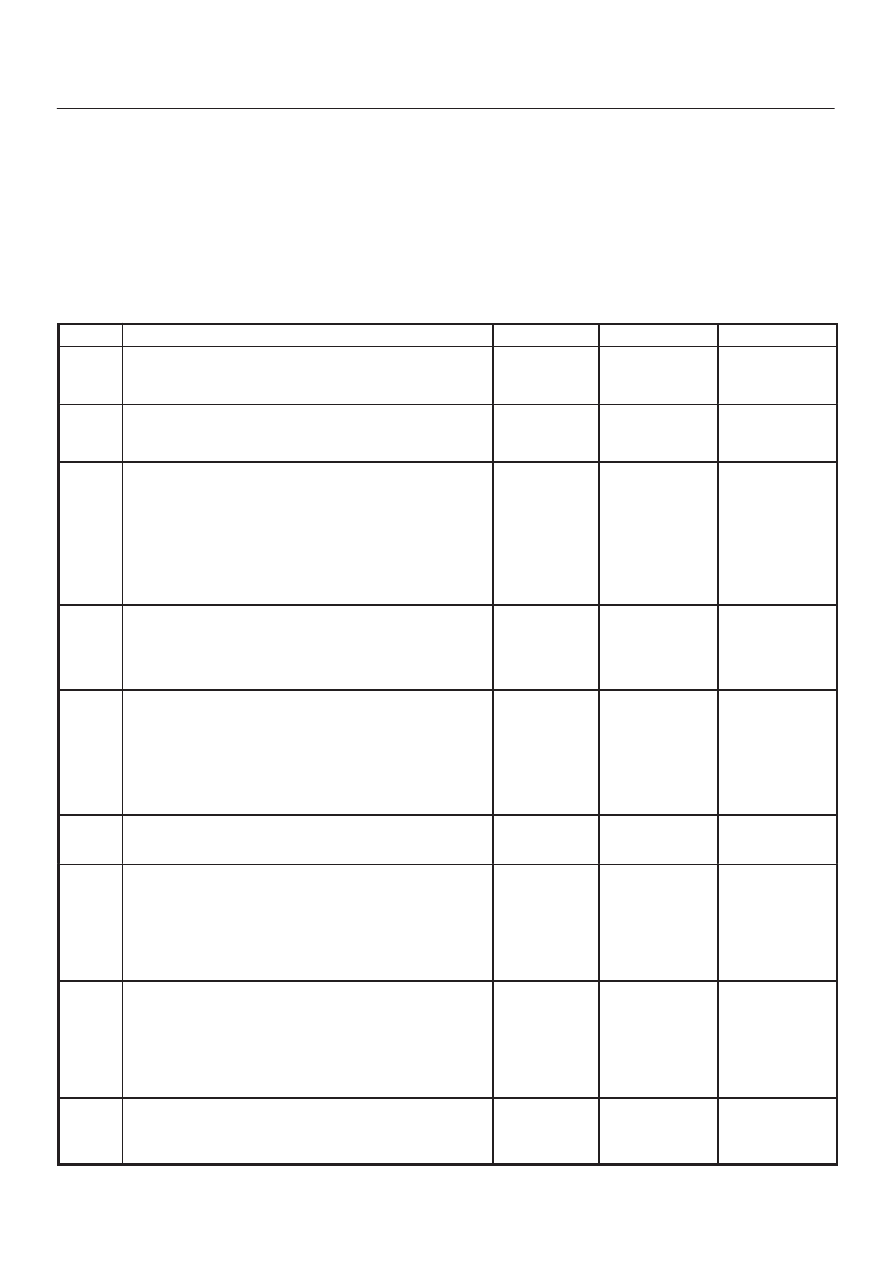

DTC P1514 - TPS-MAF Correlation Error

Step

Action

Value(s)

Yes

No

1

Was the “On-Board (OBD) System Check” performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

Was the “Electric Throttle Control (ETC) System

Check” performed?

—

Go to

Step 3

Go to

ETC

System

Check

3

1. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “DTC” info for DTC P1514.

Does the Tech 2 indicate DTC P1514 failed this

ignition?

—

Go to

Step 4

Check the

procedure.

Refer to

Diagnostic

Aids

4

1. Start the engine.

2. With the engine idling, monitor “MAF Frequency”

display on the Tech 2.

Is the “MAF Frequency” below the specified value?

3

∼

7 g/s

Go to

Step 5

Go to

Step 8

5

1. Ignition “OFF.”

2. Disconnect the MAF sensor connector.

3. Ignition “ON,” engine idling.

4. Using a Tech 2, monitor “MAF Frequency.”

Does the Tech 2 indicate a “MAF Frequency” at the

specified value?

0g/s

Go to

Step 6

Go to

Step 7

6

Replace the MAF sensor.

Is the action complete?

—

Verify repair

—

7

1. Check the MAF harness for incorrect routing near

high voltage components (solenoids, relays,

motors).

2. If incorrect routing is found, correct the harness

routing.

Was a problem found?

—

Verify repair

Go to

Step 8

8

1. With the engine idling, monitor “MAF Frequency.”

display on the Tech 2.

2. Quickly snap open throttle to wide open throttle

while under a road load and record value.

Does the Tech 2 indicate a “MAF Frequency” at

thespecified value?

3

∼

7 g/s

Go to

Step 6

Go to

Step 9

9

1. Ignition“ON”, engine not running.

2. Observe the MAP reading on the Tech 2.

Is the MAP reading less than the specified value?

100 kPa

Go to

Step 10

Go to

Step 13