Content .. 2273 2274 2275 2276 ..

Opel Frontera UBS. Manual - part 2275

6E–136

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

D

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P0106 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1107 Diagnostic Chart may isolate

the cause of the fault.

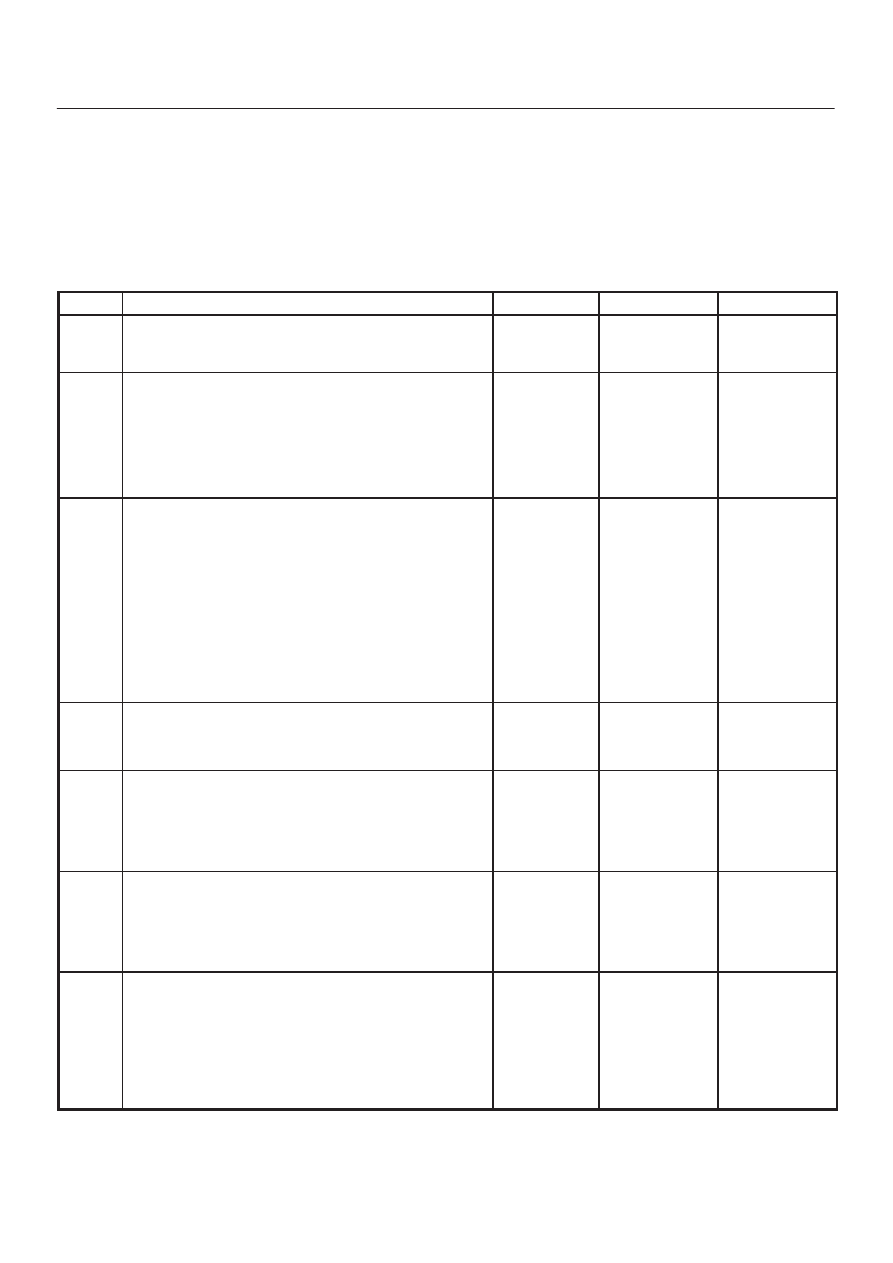

DTC P0106 – MAP System Performance

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “ON”, engine “OFF”.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “DTC” info for DTC P0106.

Does the Tech 2 indicate DTC P0106 failed?

—

Go to

Step 4

Go to

Step 3

3

1. Check for the following conditions:

D

Vacuum hoses disconnected, damaged, or

incorrectly routed

D

Intake manifold vacuum leaks

D

Vacuum leaks at throttle body

D

Vacuum leaks at EGR valve flange and pipes

D

Crankcase ventilation valve faulty, missing or

incorrectly installed.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Check the

Procedure

Refer to

Diagnostic

Aids

4

1. Disconnect the MAP sensor electrical connector.

2. Observe the MAP value displayed on the Tech 2.

Is the MAP value near the specified value?

11 kPa

Go to

Step 5

Go to

Step 13

5

1. Connect a test light between B+ and the MAP

sensor signal circuit at the MAP sensor harness

connector.

2. Observe the MAP value displayed on the Tech 2.

Is the MAP value near the specified value?

100 kPa

Go to

Step 6

Go to

Step 9

6

1. Jumper the 5 volt reference circuit and the MAP

signal circuit together at the MAP sensor harness

connector.

2. Observe the MAP value displayed on the Tech 2.

Is the MAP value near the specified value?

100 kPa

Go to

Step 7

Go to

Step 8

7

1. Ignition “OFF”.

2. Disconnect the PCM and check the sensor ground

circuit for high resistance, an open between the

PCM and the MAP sensor, or for a poor connection

at the PCM.

3. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 11