Opel Frontera UBS. Manual - part 223

POWER ASSISTED BRAKE SYSTEM 5C – 37

INSTALLATION

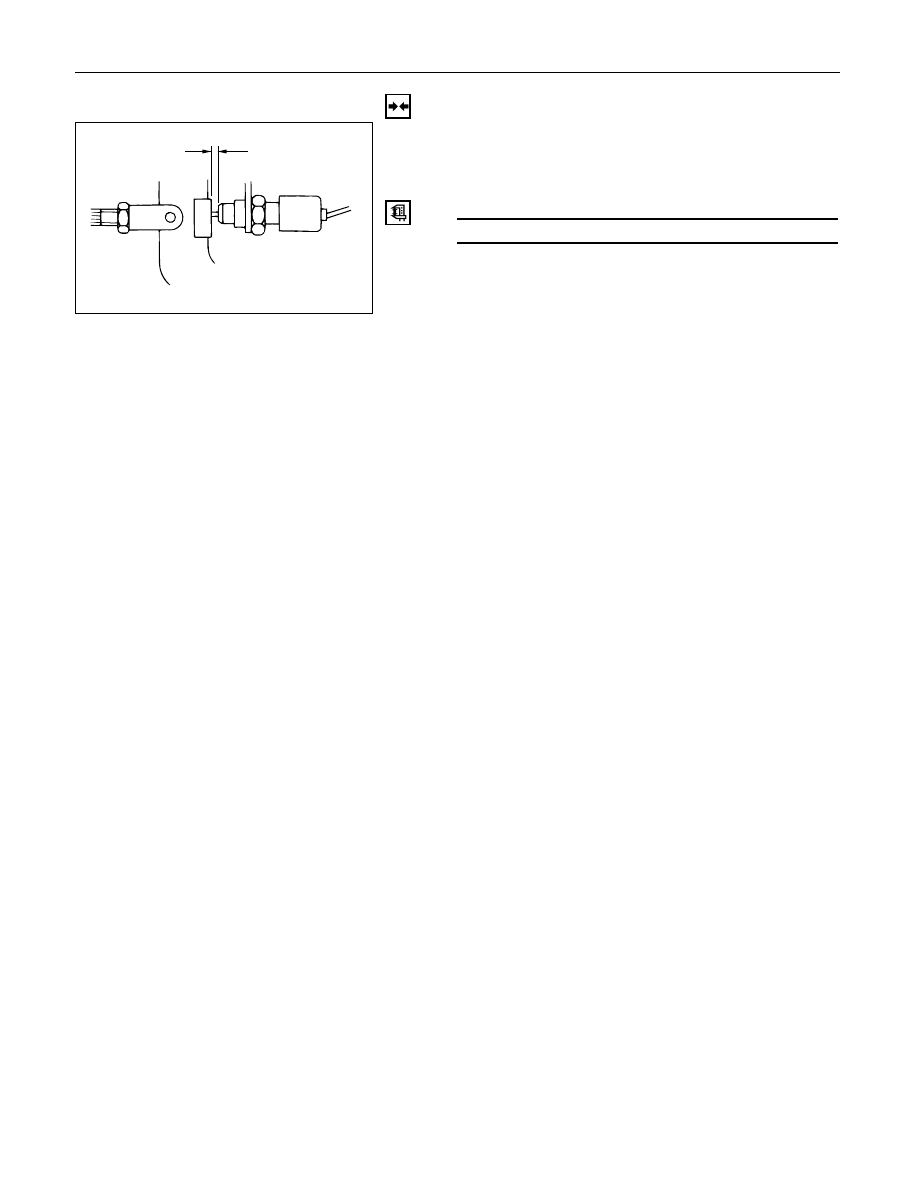

7. Switch

•

Adjust the stoplight switch to the specified

clearance (between switch housing and brake

pedal) by rotating the switch housing.

Clearance

mm (in)

0 – 0.2 (0 – 0.008)

NOTE:

While adjusting the installation of the stoplight

switch, make sure that the threaded part of the

stoplight switch does not push the brake pedal.

6. Lock Nut

5. Stoplight Switch Connector

4. Instrument Panel Driver Lower Cover Assembly

3. Lower Cluster Assembly

2. Front Console Assembly

1. Shift Knob

(A)