Content .. 2220 2221 2222 2223 ..

Opel Frontera UBS. Manual - part 2222

6A–78

ENGINE MECHANICAL (6VE1 3.5L)

015RS026

D

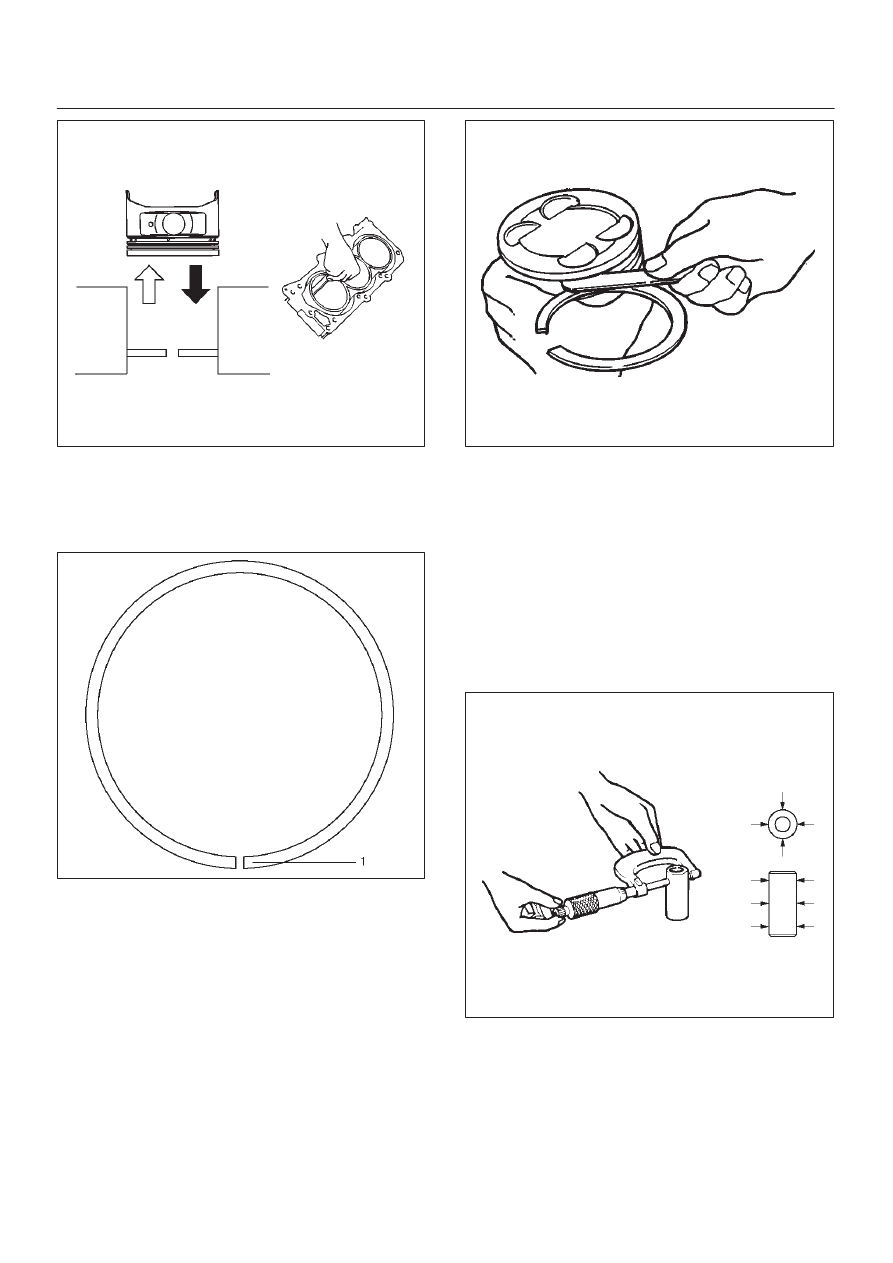

Positioning mark (1) is painted as shown in the

illustration.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

015RS027

2. Measure the clearance between the piston ring

groove and the piston ring with a feeler gauge. If the

piston ring groove / piston ring clearance exceeds the

specified limit, the piston must be replaced.

Compression Ring Clearance

Standard : 0.025 mm–0.065 mm

(0.0006 in.–0.0015 in)

Limit : 0.1mm (0.0059 in)

015RS028

Piston Pin

NOTE: Do not reuse the old piston pin.

1. Use a micrometer to measure the new piston pin

outside diameter in both directions at three different

positions.

2. Measure the inside diameter of the connecting rod

small end. If the fitting interference between the small

end and pin does not conform to the specified value,

the connecting rod must be replaced.

Standard : 0.023 mm–0.038 mm (0.0009

in–0.0015 in)

015RS029