Content .. 2219 2220 2221 2222 ..

Opel Frontera UBS. Manual - part 2221

6A–74

ENGINE MECHANICAL (6VE1 3.5L)

6. Cylinder block side bolts (6)

D

Tighten all the bolts to the specified torque in the

order shown.

NOTE: Do not apply engine oil to the crank case side

bolts.

Torque: 39 N·m (4.0 kg·m/29 lb ft)

012RS001

7. Install oil pump assembly (5), refer to “Oil pump” in

this manual.

8. Install oil strainer and O-ring (4).

9. Install oil pipe and O-ring (3) and tighten the bolts.

Torque: 25 N·m (2.6 kg·m/18 lb ft)

10. Install crankcase with oil pan (2).

1. Completely remove all residual sealant, lubricant

and moisture from the sealing surfaces. The

surfaces must be perfectly dry.

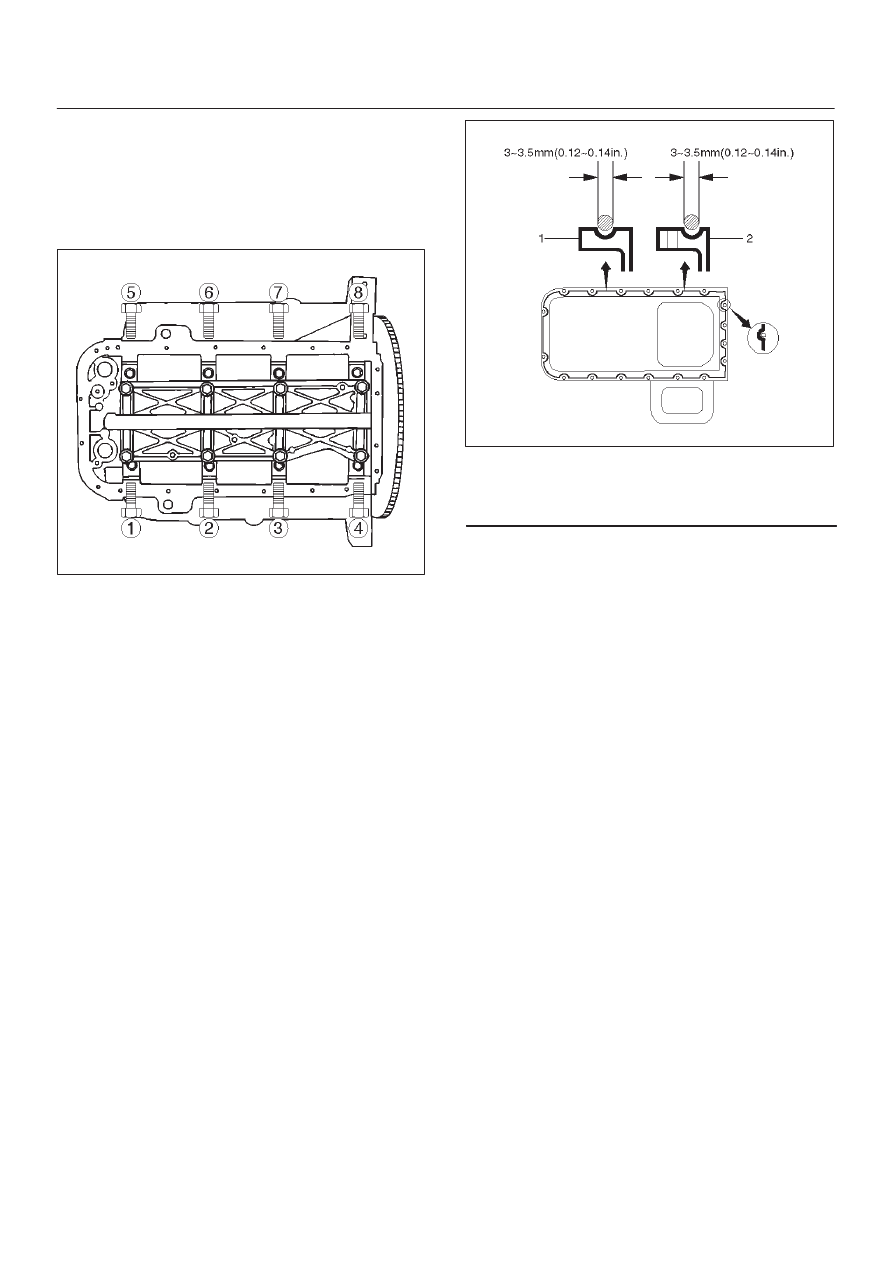

2. Apply a correct width bead of sealant (TB—

1207C or its equivalent) to the contact surfaces of

the oil pan. There must be no gaps in the bead.

3. The crankcase assembly must be installed within

5 minutes after sealant application.

4. Tighten the bolts and nuts to the specified torque.

Torque : 10 N·m (1.0 kg·m/87 lb in)

013RW010

Legend

(1) Portion Between Bolt Holes

(2) Bolt Hole Portion

11. Install cylinder head assembly, refer to “Cylinder

head” in this manual.