Content .. 2215 2216 2217 2218 ..

Opel Frontera UBS. Manual - part 2217

6A–58

ENGINE MECHANICAL (6VE1 3.5L)

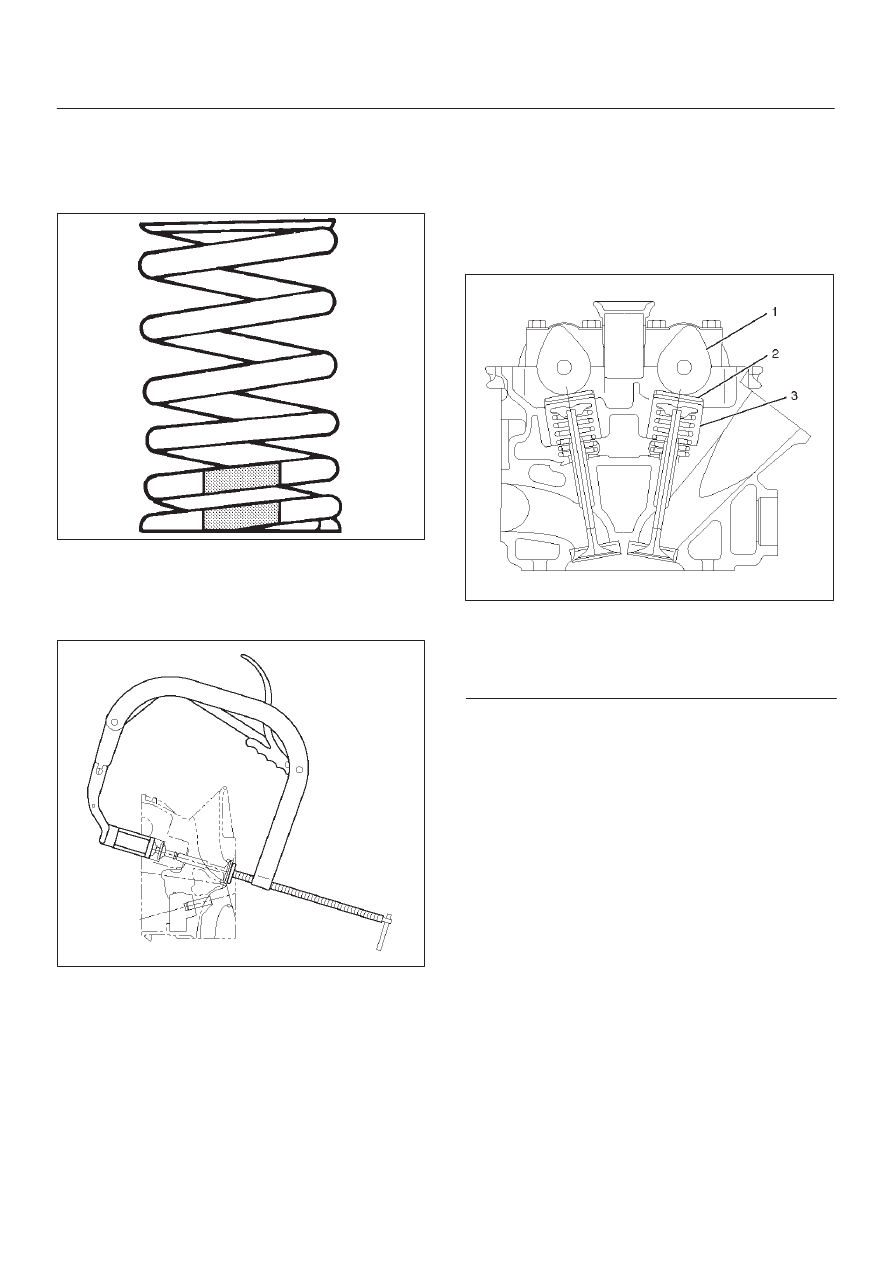

3. Install valve to valve guide. Before installing valve

guide apply engine oil to the outside of the valve stem.

4. Install valve spring to cylinder head. Attach the valve

spring to the lower spring seat. The painted area of

the valve spring should be facing downward.

014RS020

5. Install lower valve spring seat, valve spring and upper

valve spring seat then put split collars on the upper

spring seat, using the 5-8840-2446-0 valve spring

compressor and 5-8840-2547-0 valve spring

compressor adapter to install the split collars.

014RW042

6. Install tappet with shim.

7. Install camshaft assembly.

D

Refer to installation procedure for Camshaft in this

manual.

Valve Clearance Adjustments

NOTE: To adjust valve clearance, apply engine oil to the

cam as well as to the adjusting shim (2) with the cylinder

head built on the cylinder block, give a few turns to the

camshaft by means of timing pulley tightening bolt, and

measure valve clearance when the nose of cam is just

opposite of maximum cam lift (1) as shown in illustration

below.

014RW081

Legend

(1) Cam

(2) Shim

(3) Tappet

Valve Clearance Standard Value (cold)

Intake: 0.23 mm–0.33 mm

(0.0091 in–0.0130 in)

Exhaust: 0.25 mm–0.35 mm

(0.0098 in–0.0138 in)

Selection of Adjusting Shim

Shim to be selected = (Thickness of removed shim) +

(Valve clearance measurement – Standard value)

Based on the above formula, the best suited shim should

be selected from 41 types of shim (differently thick at

0.02mm (0.0008 in) intervals from 2.40mm (0.0945 in)

through 3.2mm (0.1260 in) thick). Install the shim and

check valve clearance.