Content .. 2214 2215 2216 2217 ..

Opel Frontera UBS. Manual - part 2216

6A–54

ENGINE MECHANICAL (6VE1 3.5L)

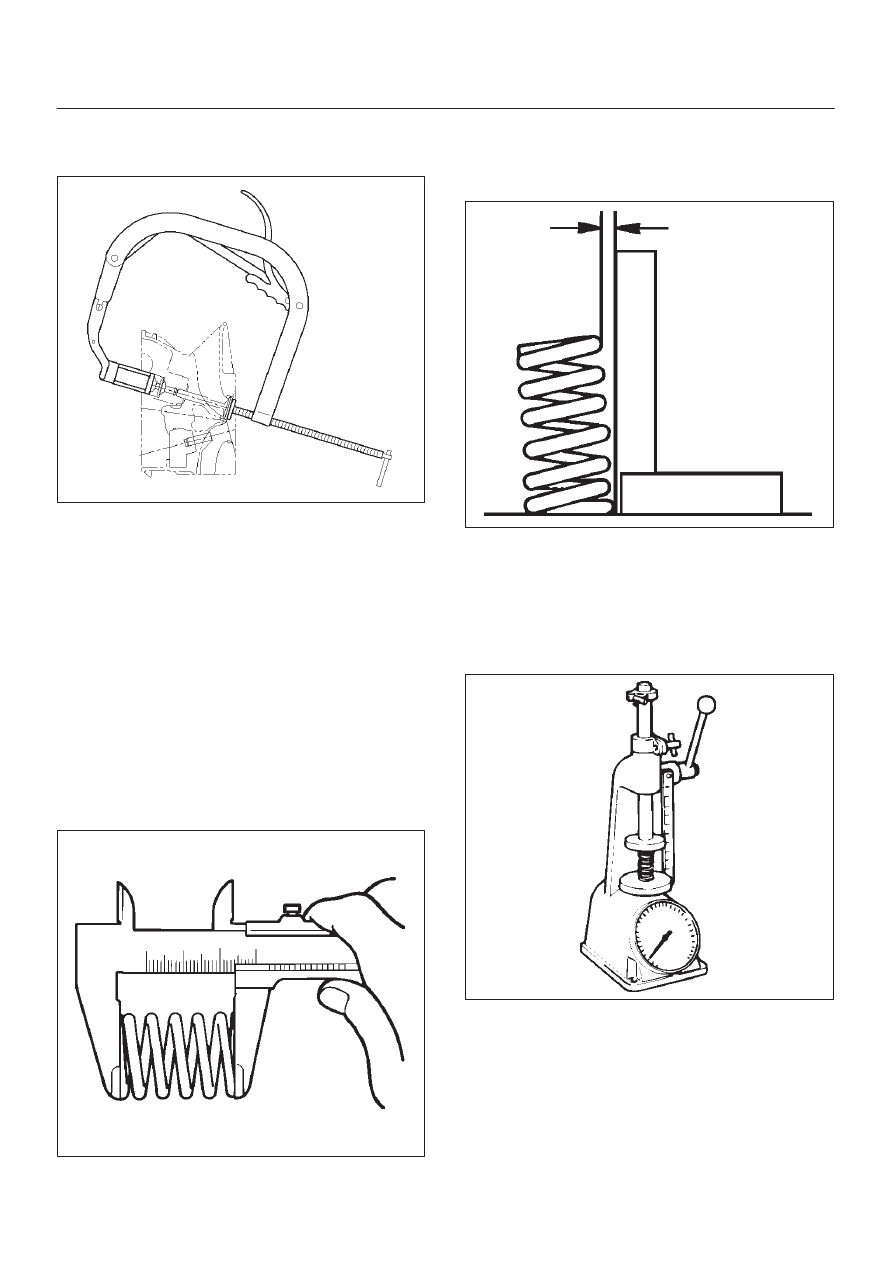

5. Use the 5-8840-2446-0 valve spring compressor and

5-8840-2547-0 valve spring compressor adapter to

remove split collar.

014RW042

6. Remove valve spring.

7. Remove valve.

8. Remove oil controller and spring lower seat.

9. Remove the valve guide using the 5-8840-2442-0

valve guide replacer.

Inspection and Repair

Valve Spring

CAUTION: Visually inspect the valve springs and

replace them if damage or abnormal wear is evident.

1. Measure the free height of the springs. The springs

must be replaced if the free height is below the

specified limit.

Standard : 44.6 mm (1.756 in)

Limit : 43.6 mm (1.717 in)

014RS004

2. Measure the valve spring squareness with a steel

square and replace the valve springs if the measured

value exceeds the specified limit.

Limit : 2 mm (0.079 in)

014RS005

3. Using a spring tester to compress the springs to the

installed height, measure the compressed spring

tension, and replace the springs if the measured

tension is below the specified limit.

At installed height: 35.0 mm (1.38 in)

Standard: 196 N (20.0 kgf/44 lb)

Limit: Less than 181 N (18.5 kgf/41 lb)

014RS006

Valve Guide

CAUTION: Take care not to damage the valve seat

contact surface, when removing carbon adhering to

the valve head. Carefully inspect the valve stem for

scratches or abnormal wear. If these conditions are

present, the valve and the valve guide must be

replaced as a set.