Content .. 2179 2180 2181 2182 ..

Opel Frontera UBS. Manual - part 2181

6E–297

ENGINE DRIVEABILITY AND EMISSIONS

Mass Air Flow (MAF) Sensor

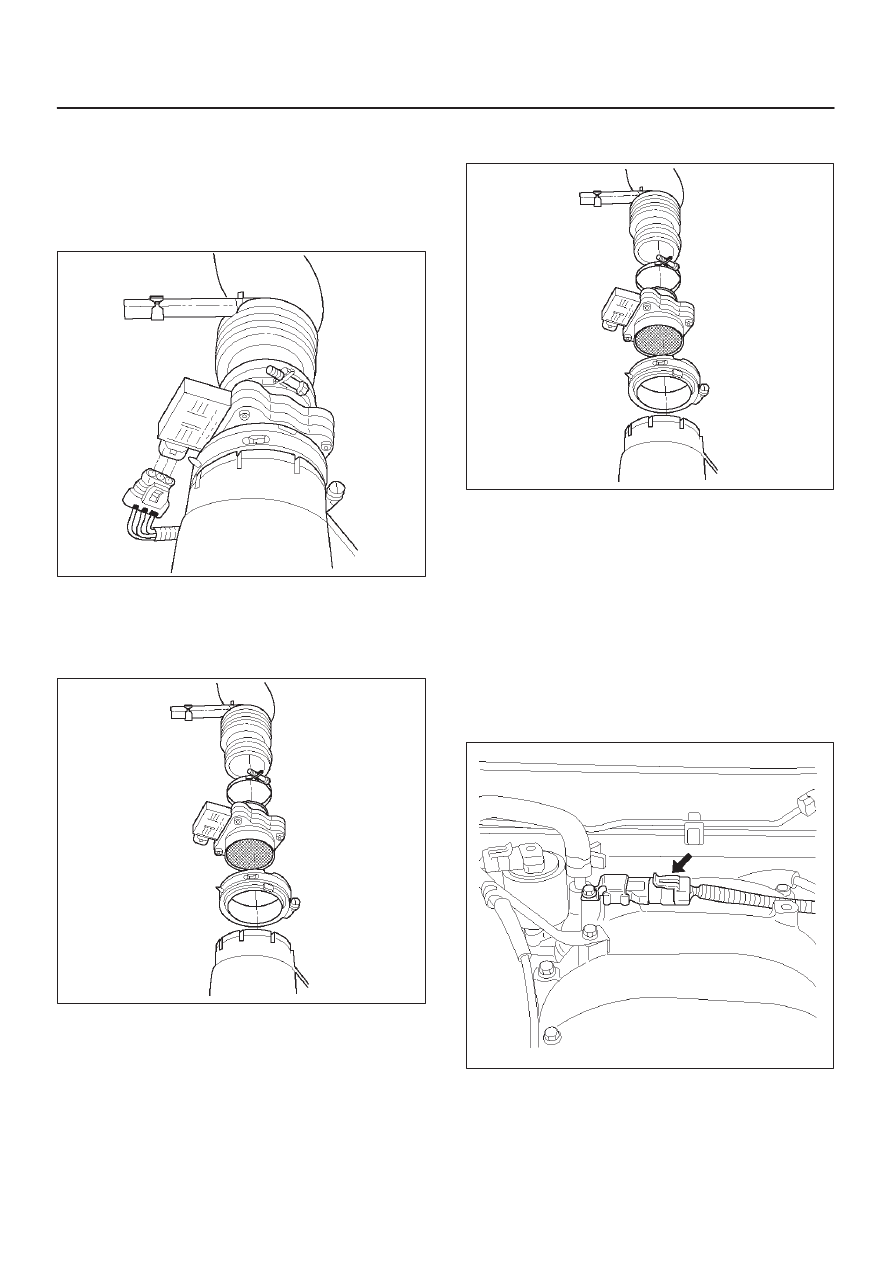

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the MAF

sensor.

TS23740

3. Loosen the clamps which secure the intake air duct

and the air cleaner to the MAF sensor.

4. Remove the intake air duct from the MAF sensor.

5. Remove the MAF sensor from the air cleaner.

TS23781

Installation Procedure

1. Install the MAF sensor on the air cleaner with the

clamp.

2. Install the intake air duct and the clamp on the MAF

sensor.

TS23781

3. Tighten the clamps to secure the MAF sensor to the

intake air duct and the air cleaner.

4. Connect the MAF electrical connector.

5. Connect the negative battery cable.

Manifold Absolute Pressure

(MAP) Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the MAP

sensor.

055RW005

3. Remove the bolt securing the MAP sensor to the

mounting bracket on the common chamber.