Content .. 2049 2050 2051 2052 ..

Opel Frontera UBS. Manual - part 2051

5C – 16 POWER ASSISTED BRAKE SYSTEM

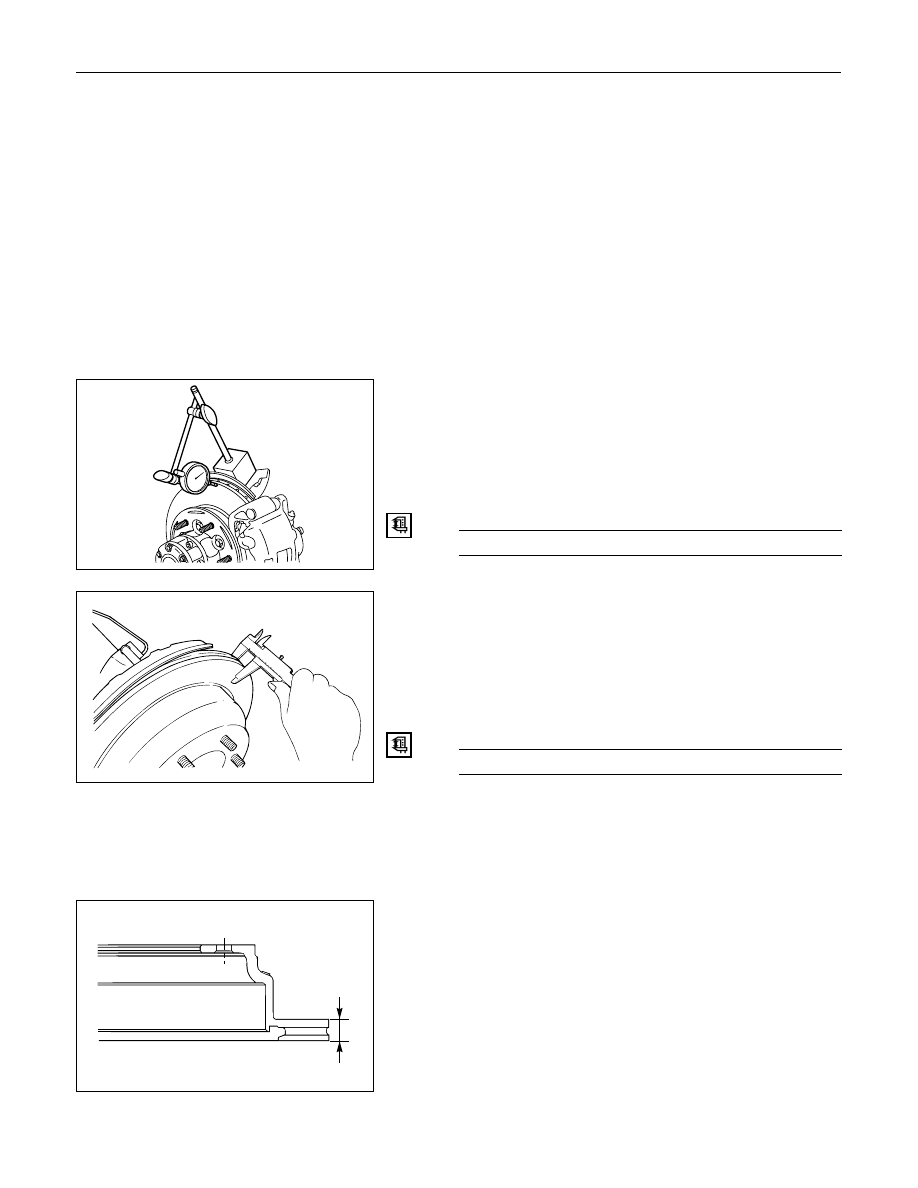

PARALLELSIM

Parallelism is the measurement of the thickness of the

rotor at four or more points around the circumference

of the rotor. All measurements must be made at 22 mm

(0.87 in) from the edge of the rotor.

The rotor thickness must not vary more than 0.010

mm (0.0004 in) from point to point.

Maximum Parallelism Variation

mm (in)

0.010 (0.0004)

REPLACING REAR BRAKE ROTORS

When installing new brake rotors, do not refinish the

surfaces. These parts are at the correct level of surface

finish.

REFINISHING REAR BRAKE ROTORS

Accurate control of the rotor tolerances is necessary

for proper performance of the disc brakes. Machining

of the rotor should be done only with precision

equipment. All brake rotors have a minimum

thickness dimension cast into them. This dimension is

the minimum wear dimension and not a refinish

dimension. The minimum wear dimension is 16.60

mm (0.654 in). The refinish dimension is 16.97 mm

(0.668 in).

When refinishing rotors, always use sharp cutting

tools or bits. Dull or worn tools leave a poor surface

finish which will affect initial braking performance.

SERVICING THE REAR BRAKE ROTOR

In the manufacturing of the rear brake rotor, all the

tolerances regarding surface finish, parallelism and

lateral runout are held very closely. The maintenance

of these tolerances provide the surface necessary to

assure smooth brake operation.

LATERAL RUNOUT

Lateral runout is the movement of the rotor from side

to side as it rotates on the spindle. This could also be

referred to as “rotor wobble”.

This movement causes the piston to be knocked back

into its bore. This results in additional pedal travel and

a vibration during braking.

CHECKING LATERAL RUNOUT

1. Attach a dial indicator to some portion of the

suspension so that the stem contacts the rotor

face about 22 mm (0.87 in) from the rotor edge.

2. Move the rotor one complete rotation.

•

The lateral runout should not exceed 0.13 mm

(0.005 in).

Maximum Runout

mm (in)

0.13 (0.005)

t