Content .. 2000 2001 2002 2003 ..

Opel Frontera UBS. Manual - part 2002

4C–32

DRIVE SHAFT SYSTEM

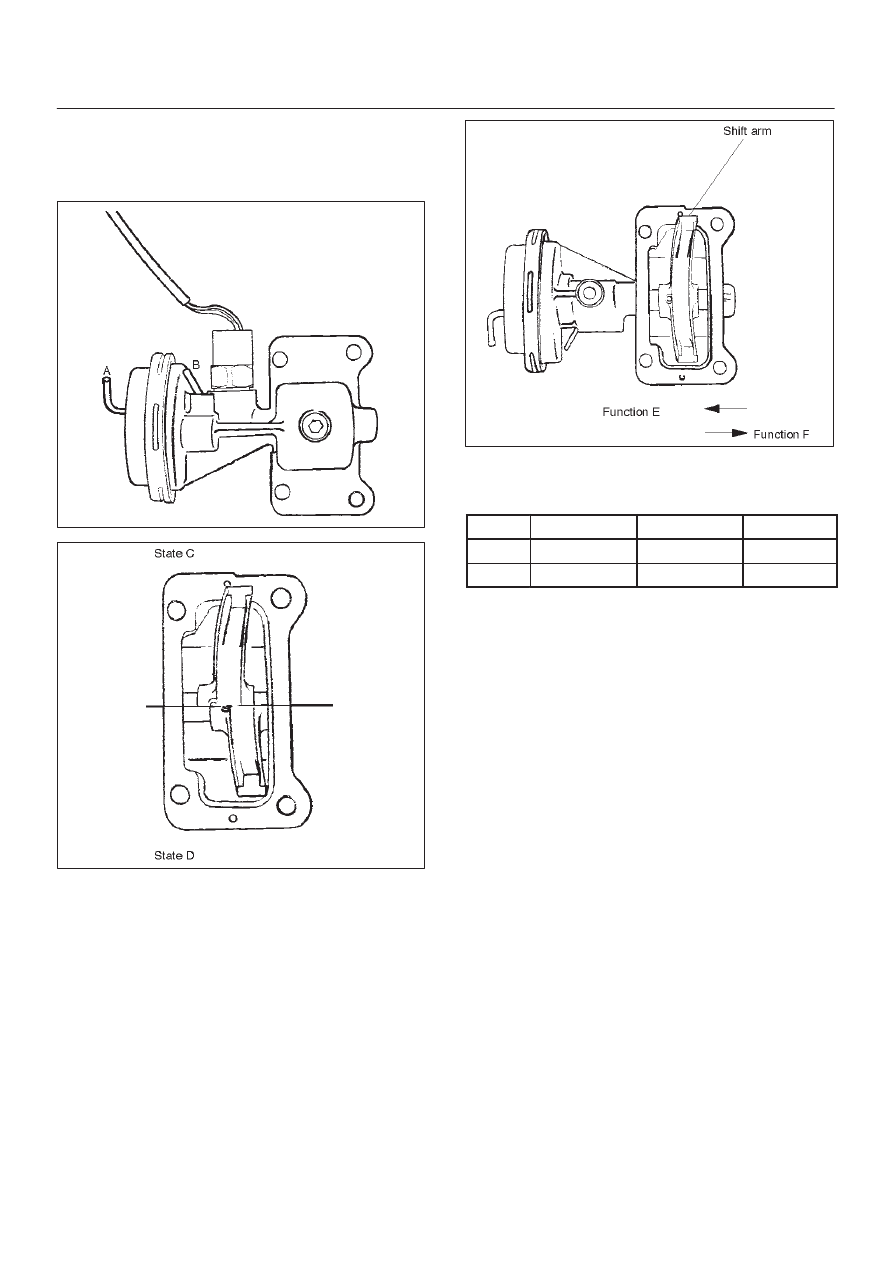

Actuator

Check and see that there is no damage, cracking, or other

abnormality.

Functional Check

412RW021

412RW013

412RW007

Disconnect the shift position switch and make sure of

function with a vacuum of –400 mmHg applied to Ports A

and B, in accordance with the table below.

State

Port A

Port B

Function

C

–400 mmHg

A/P

E

D

A/P

–400 mmHg

F

If there is an abnormality, replace the actuator as an

assembly.

NOTE:

1. If the actuator works under –400mmHg or less, there

is no functional problem.

2. Be careful not to permit the entry of water or dust into

the ports of the actuator.

Dimensional Check

Measure illustrated sizes 1, 2, and 3.

Limit

1=64.3 mm (2.53 in) max.

2=6.7 mm (0.26 in) min.

3=6.7 mm (0.26 in) min.