Opel Frontera UBS. Manual - part 168

4C–29

DRIVE SHAFT SYSTEM

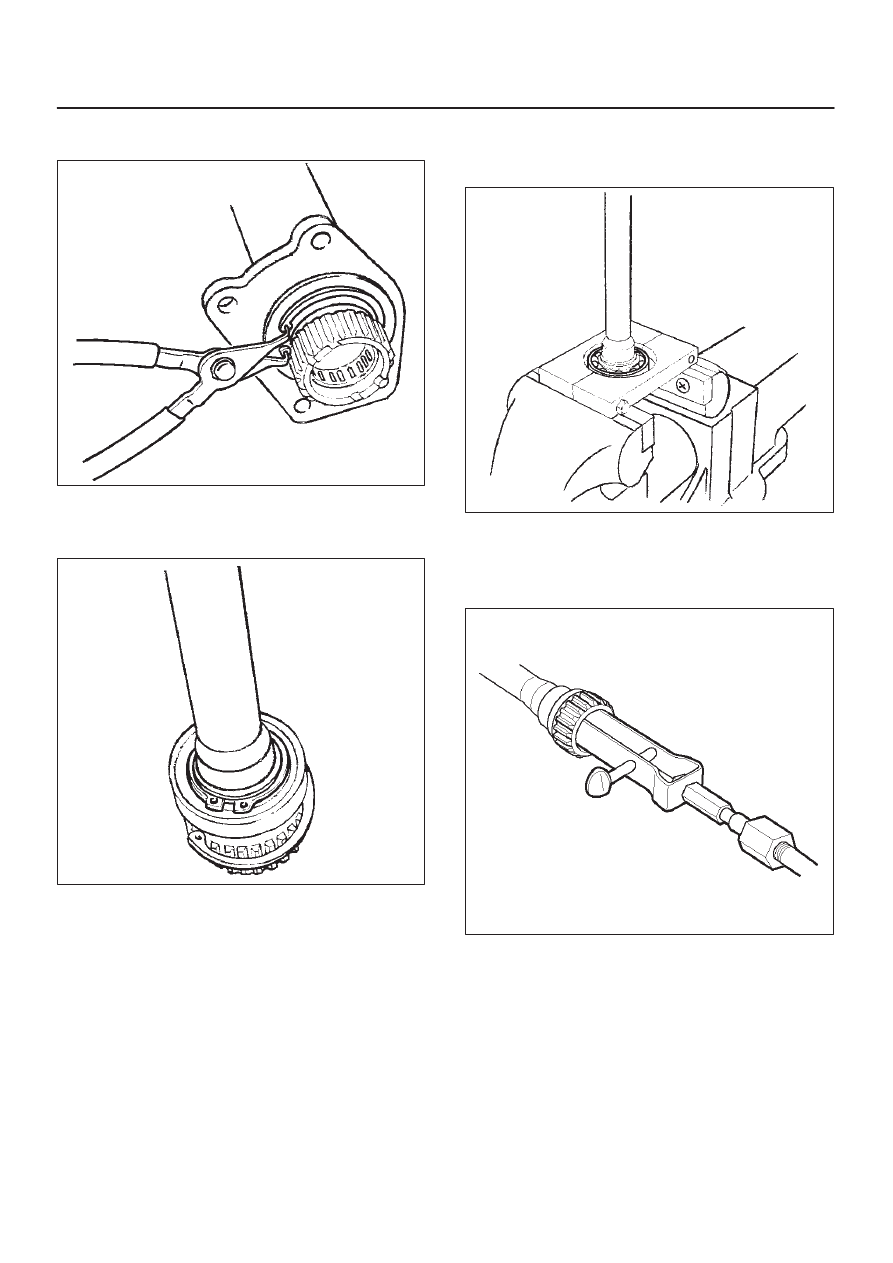

7. Remove snap ring from front axle case by using snap

ring pliers.

412RW017

8. Take out inner shaft from front axle case.

9. Remove snap ring from inner shaft by using snap ring

pliers.

412RW016

10. Remove inner shaft bearing by using a remover

5–8840–2197–0 and press.

NOTE: Be careful not to damage the shaft.

412RW015

11. Remove needle bearing from inner shaft by using a

remover 5–8840–0027–0 and sliding hammer

5–8840–0084–0.

NOTE: Be careful not to damage the shaft.

412RS045

12. Remove oil seal from front axle case.

NOTE: Be careful not to damage the front axle case.