Content .. 1359 1360 1361 1362 ..

Opel Frontera UBS. Manual - part 1361

6E–38

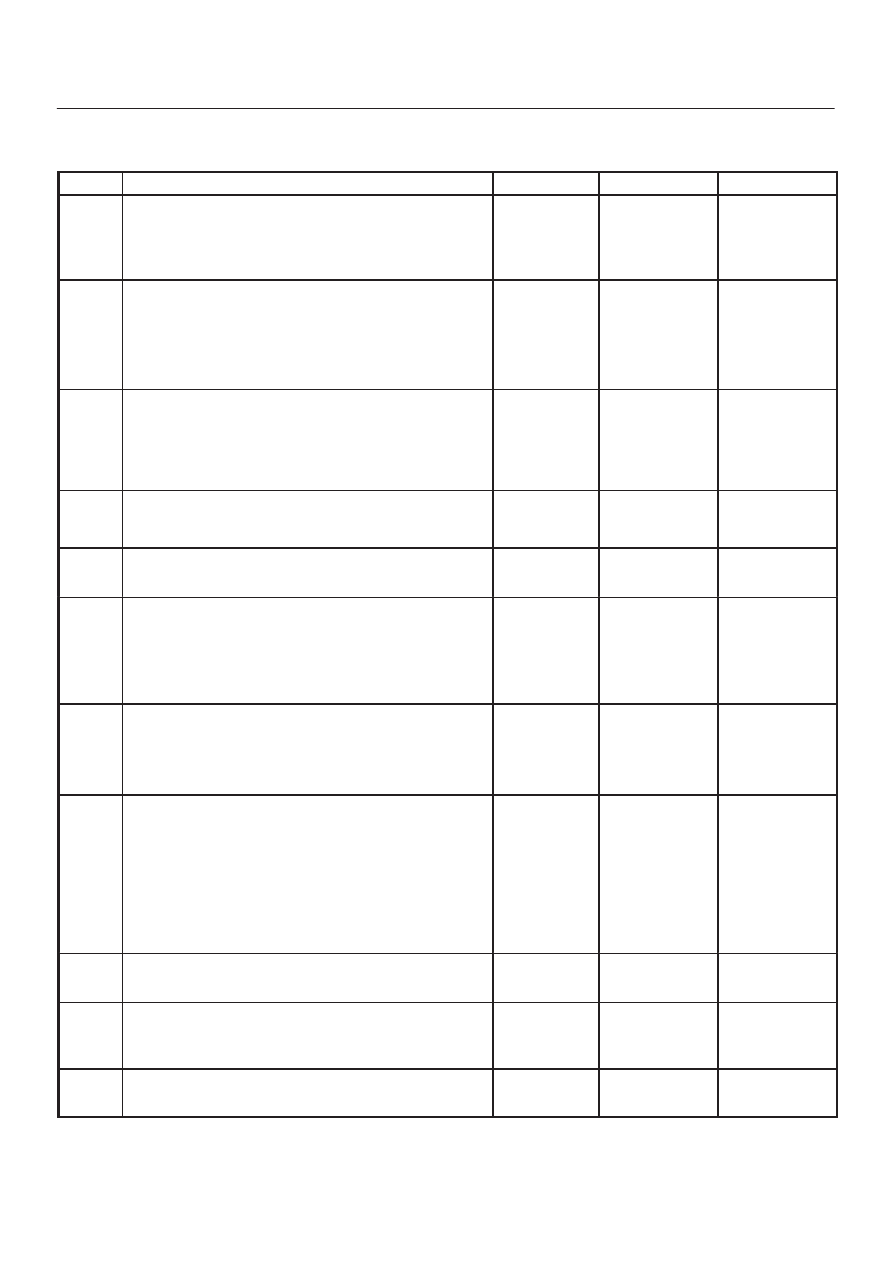

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

On- Board Diagnostic (OBD) System Check

Step

Action

Value(s)

Yes

No

1

1. Ignition “ON,” engine “OFF.”

2. Observe the malfunction indicator lamp (MIL or

“Check Engine” lamp).

Is the MIL (“Check Engine” lamp)“ON?”

—

Go to

Step 2

Go to

No MIL

(“Check

Engine” lamp)

2

1. Ignition “OFF.”

2. Install a Tech 2.

3. Ignition “ON.”

4. Attempt to display ECM engine data with the Tech 2.

Does the Tech 2 display ECM data?

—

Go to

Step 3

Go to

Step 8

3

1. Using the Tech 2 output tests function, select MIL

(“Check Engine” lamp) dash lamp control and

command the MIL (“Check Engine” lamp) “OFF.”

2. Observe the MIL (“Check Engine” lamp).

Did the MIL (“Check Engine” lamp) turn “OFF?”

—

Go to

Step 4

Go to

MIL

(“Check

Engine” lamp)

On Steady

4

Attempt to start the engine.

Did the engine start and continue to run?

—

Go to

Step 5

Go to

Cranks

But Will Not

Run

5

Select “Display DTCs” with the Tech 2.

Are any DTCs stored?

—

Go to

Step 6

Go to

Step 7

6

Are two or more of the following DTCs stored?

A Group; P0337, P0342, P1193, P1404, P1405,

P1488

B Group; P0337, P0342

C Group; P0112, P0117, P0182, P0197

D Group; P0107, P0405, P1194, P1485

—

Go to

Chart,

“Multiple

ECM

Information

Sensor DTCs

Set”

Go to

applicable

DTC table

7

Compare ECM data values displayed on the Tech 2 to

the typical engine scan data values.

Are the displayed values normal or close to the typical

values?

—

Go to

Step 8

Refer to

indicated

Component

System

Checks

8

1. Ignition “OFF,” disconnect the ECM.

2. Ignition “ON,” engine “OFF.”

3. Check the Class 2 data circuit for an open, short to

ground, or short to voltage. Also, check the DLC

ignition feed circuit for an open or short to ground

and the DLC ground circuit for an open.

4. If a problem is found, repair as necessary.

Was a problem found?

—

Go to

Step 2

Go to

Step 9

9

Check the Tech 2 on other vehicle.

Was Tech 2 abnormal?

—

Go to

Step 11

Go to

Step 10

10

Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—

Go to

Step 2

—

11

Repair the Tech 2 or prepare another Tech 2.

Is the action complete?

—

Go to

Step 2

—