Content .. 1274 1275 1276 1277 ..

Opel Frontera UBS. Manual - part 1276

ENGINE MECHANICAL 6A – 37

•

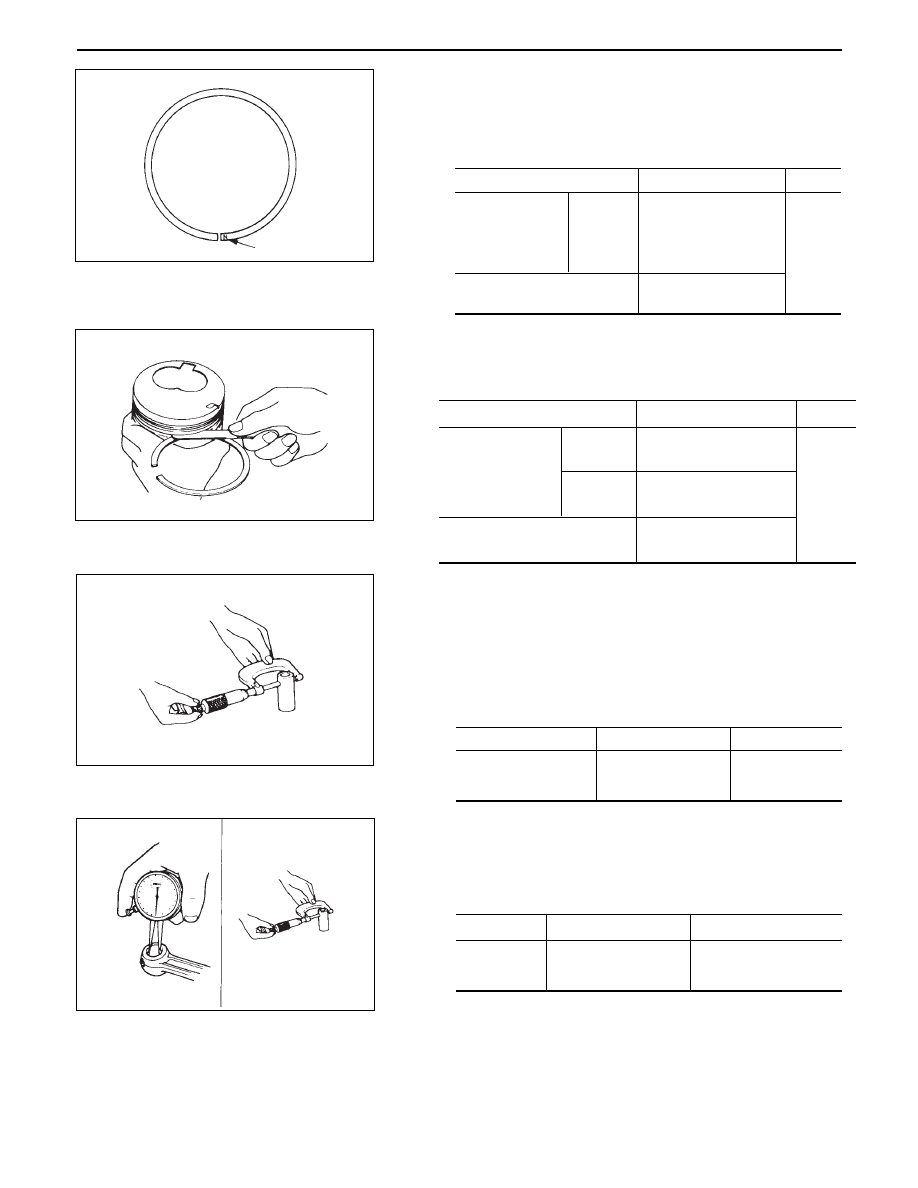

Push the ring by the piston, at a right angle to the

wall, into the point at which the cylinder bore

diameter is the smallest.

•

Measure the ring end gap.

Standard

Compression

ring

Limit

1st/2nd

0.20-0.35

(0.0079-0.0138)

1.5

(0.0591)

0.10-0.30

(0.0039-0.0118)

Oil ring

mm(in)

2.

Measure the clearance between the piston ring groove

and the piston ring with a feeler gauge. If the piston ring

groove/piston ring clearance exceeds the specified limit,

the piston must be replaced.

Standard

Compression

ring

Limit

Top

0.05-0.09

(0.0020-0.0035)

2nd

0.05-0.09

(0.0020-0.0035)

0.15

(0.0059)

0.03-0.07

(0.0012-0.0028)

Oil ring

mm(in)

Piston pin

Visually inspect the piston pin for cracks, flaws, and other

damage and replace if necessary.

1.

Use a micrometer to measure the piston pin outside

diameter in both directions at three different

positions. If the measurement exceed the specified

limit, the piston pin must be replaced.

Standard

Piston pin outside

diameter

Limit

33.995-34.000

(1.3384-1.3386)

33.970

(1.3374)

mm (in)

2.

Measure the inside diameter of the connecting rod

small end. If the clearance between the small end

and pin does not conform to the specified value, the

connecting rod or bushing and pin must be replaced.

Standard

Limit

0.008 ~ 0.020

(0.0003 ~ 0.0008)

0.05

(0.0020)

Clearance

mm (in)