Opel Frontera UBS. Manual - part 126

4A2B–24

DIFFERENTIAL (REAR 244mm)

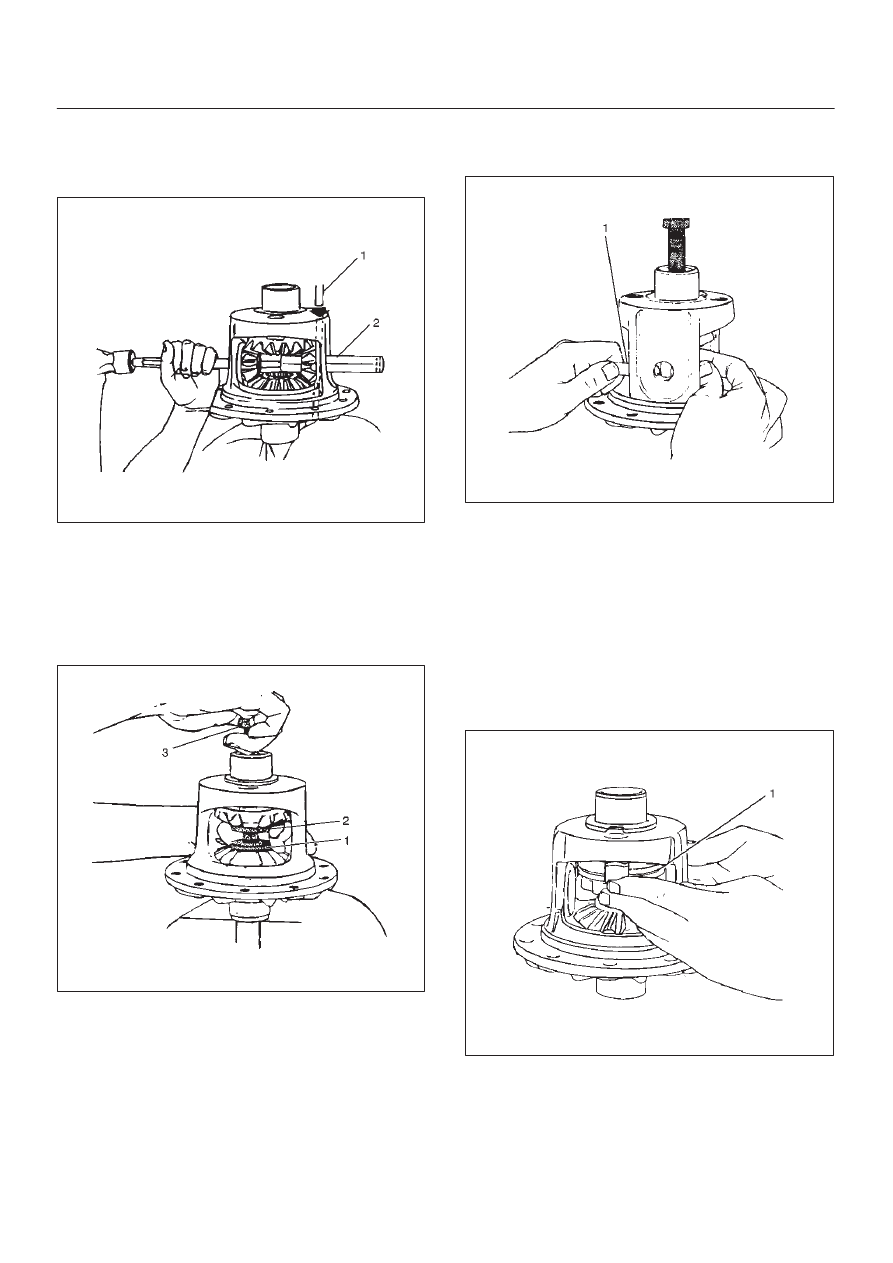

4. Remove Differential shaft (2) using hammer and

punch.

Place shop towel behind case to prevent differential

shaft from dropping out of case.

425RW005

5. Assemble clutch pack unloading tool

5–8840–2586–0 .

a. Install cap (1) to the bottom differential side gear.

b. Install threaded screw cap (2) to top differential

side gear. Thread forcing screws (3) into threaded

screw cap until it becomes centered into the

bottom cap.

425RW064

c. Tighten forcing screw until tight enough to collapse

dished spacers and allow looseness between side

and pinion mate gears.

6. Both pinion mate gear thrust washers using a shim

stock (1) of 0.51 mm (0.020 in.) or equivalent tool to

push out washers.

425RW007

7. Relieve tension of dished spacers by loosening

forcing screw.

NOTE:

D

You may have to adjust the forcing screw slightly to

allow the case to rotate.

8. Insert differential shaft into its hole of case. Pull on

shaft and rotate case until pinion mate gears can be

removed.

9. Remove pinion mate gears.

10. Hold side gear top clutch pack (1) with one hand and

remove positraction unloading tools.

425RW008