Content .. 1237 1238 1239 1240 ..

Opel Frontera UBS. Manual - part 1239

6E–322

ENGINE DRIVEABILITY AND EMISSIONS

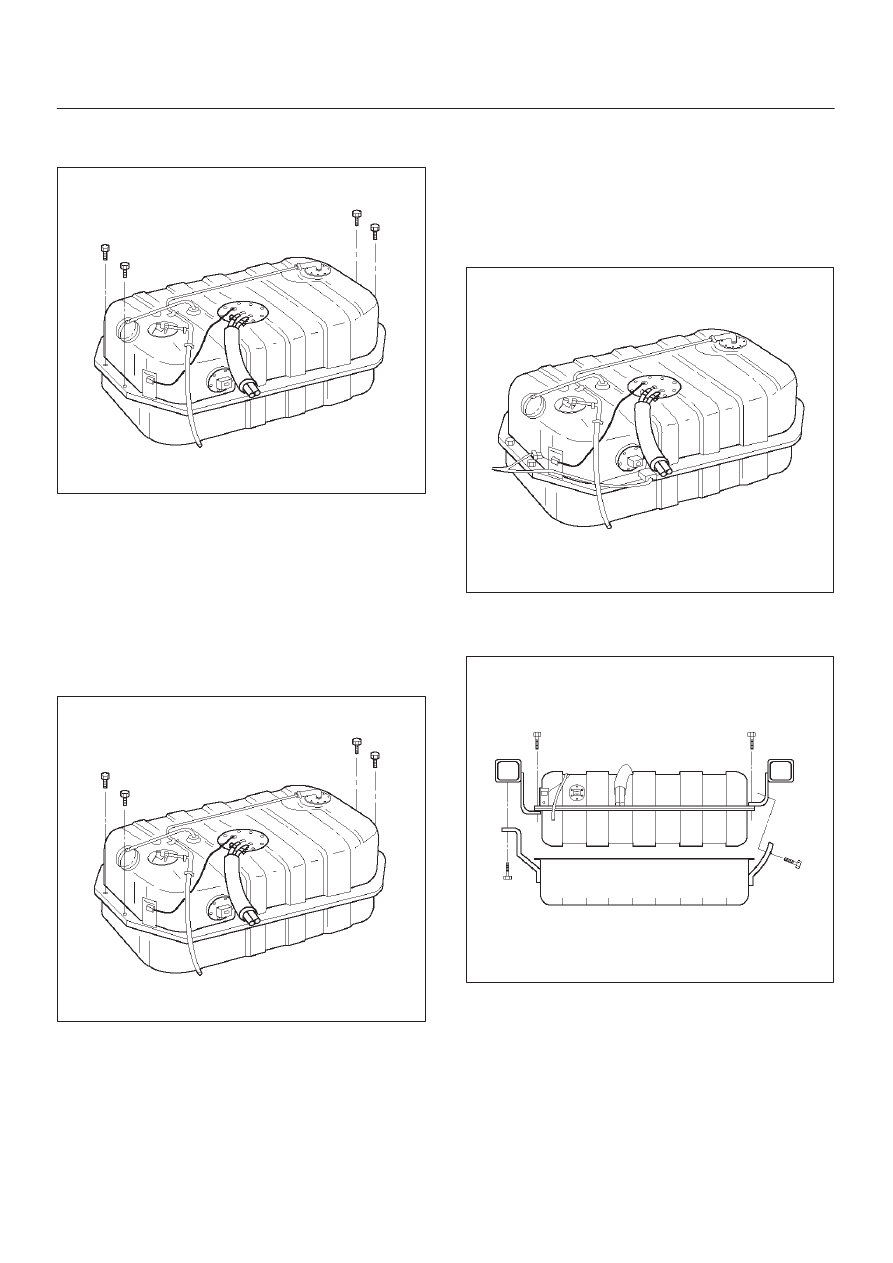

15. Remove the fuel tank retaining bolts on both sides.

16. Remove the fuel tank.

TS23770

Installation Procedure

1. Install the fuel tank.

D

Place the flanges on the left and right side of the

tank on the bracket.

2. Install the fuel tank retaining bolts.

Tighten

D

Tighten the fuel tank retaining bolts to 36 N·m (27 lb

ft.).

TS23770

3. Connect the fuel return hose.

4. Connect the fuel supply hose.

5. Connect the EVAP vapor hose.

6. Connect the wiring connector for the fuel gauge unit.

7. Connect the fuel gauge wiring connector to the

bracket.

8. Connect the wiring connector for the fuel pump.

TS23769

9. Install the undercover.

10. Secure the undercover with the retaining bolts.

TS23797