Content .. 1056 1057 1058 1059 ..

Opel Frontera UBS. Manual - part 1058

4C–49

DRIVE SHAFT SYSTEM

Removal

1. Jack up the vehicle and support it on the chassis

stands.

2. Gear shift lever should be placed in neutral position

and parking brake released.

NOTE: Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

401RS023

3. Remove bolt, nut and washer (Rear axle side).

4. Remove bolt, nut and washer (Transfer side).

5. Remove rear propeller shaft.

Installation

NOTE: Never install the shaft assembly backwards.

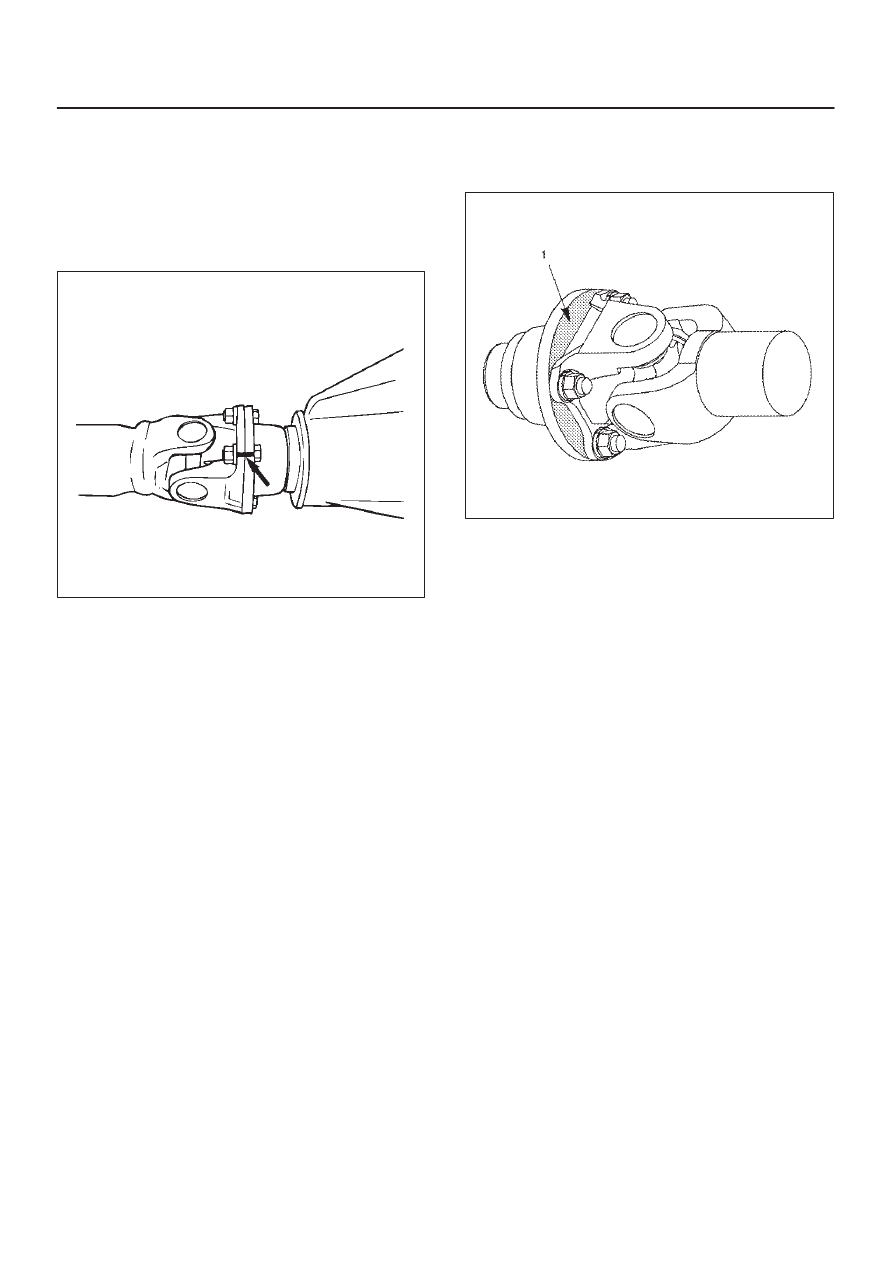

1. Completely remove the black paint from the

connecting surface of flange coupling on each end of

propeller shaft. Clean so that no foreign matter will be

caught in between.

2. Align the mark which is applied at removal .

Install rear propeller shaft and tighten the bolts to the

specified torque.

Torque: 63 N·m (6.4 kg·m/46 lb ft)

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS022