Opel Frontera UE. Manual - part 915

6E2–46

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

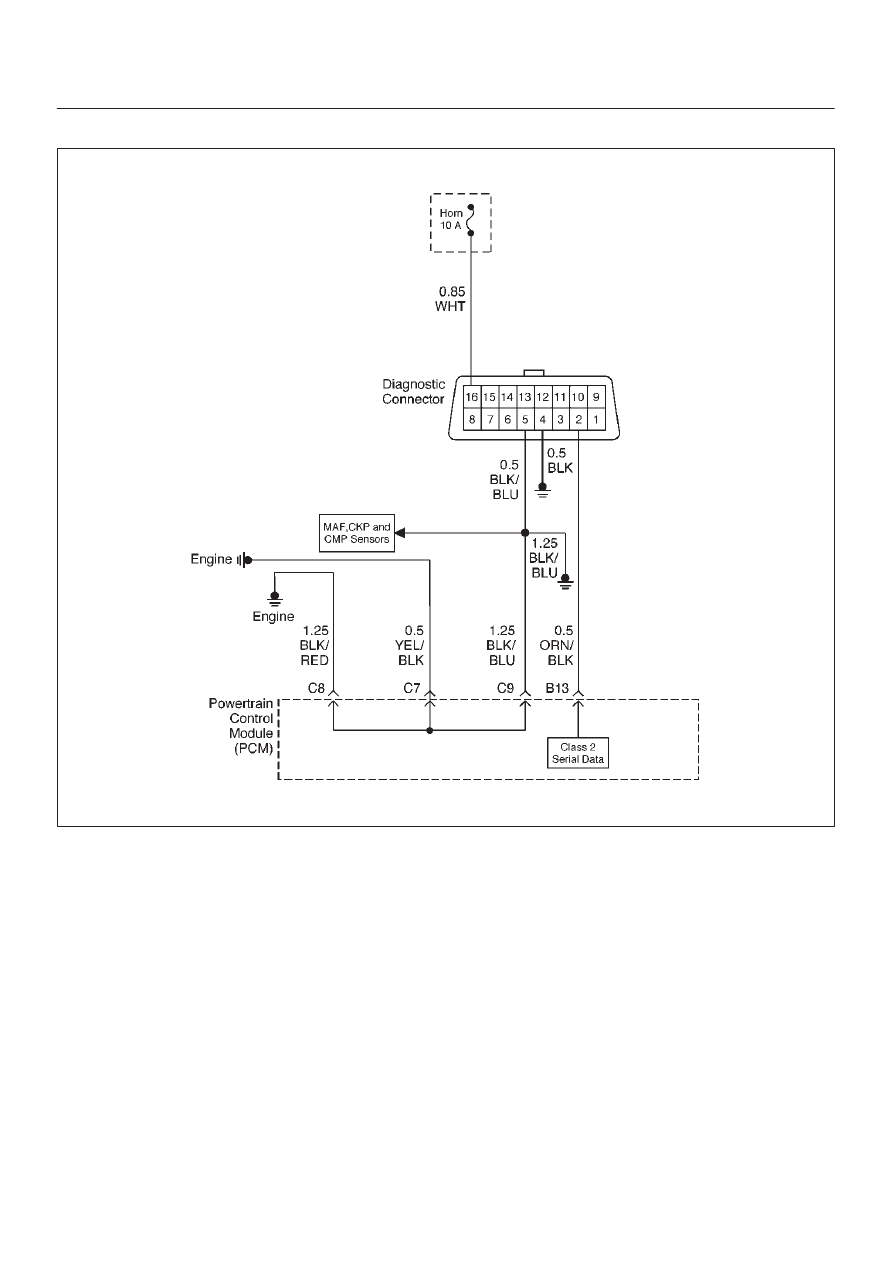

On-Board Diagnostic (OBD) System Check

D06RX010

Circuit Description

The on-board diagnostic system check is the starting

point for any driveability complaint diagnosis. Before

using this procedure, perform a careful visual/physical

check of the PCM and engine grounds for cleanliness and

tightness.

The on-board diagnostic system check is an organized

approach to identifying a problem created by an

electronic engine control system malfunction.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for poor connections or a damaged

harness. Inspect the PCM harness and connector for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

1. The MIL (“Check Engine” lamp) should be “ON”

steady with the ignition “ON”/engine “OFF.” If not,

the “No MIL” chart should be used to isolate the

malfunction.

2. Checks the Class 2 data circuit and ensures that the

PCM is able to transmit serial data.

3. This test ensures that the PCM is capable of

controlling the MIL (“Check Engine” lamp) and the

MIL (“Check Engine” lamp) driver circuit is not

shorted to ground.

4. If the engine will not start, the

Cranks But Will Not

Run chart should be used to diagnose the condition.

7. A Tech 2 parameter which is not within the typical

range may help to isolate the area which is causing

the problem.