Opel Frontera UE. Manual - part 889

6B–4

ENGINE COOLING (6VD1 3.2L)

B06RW002

D

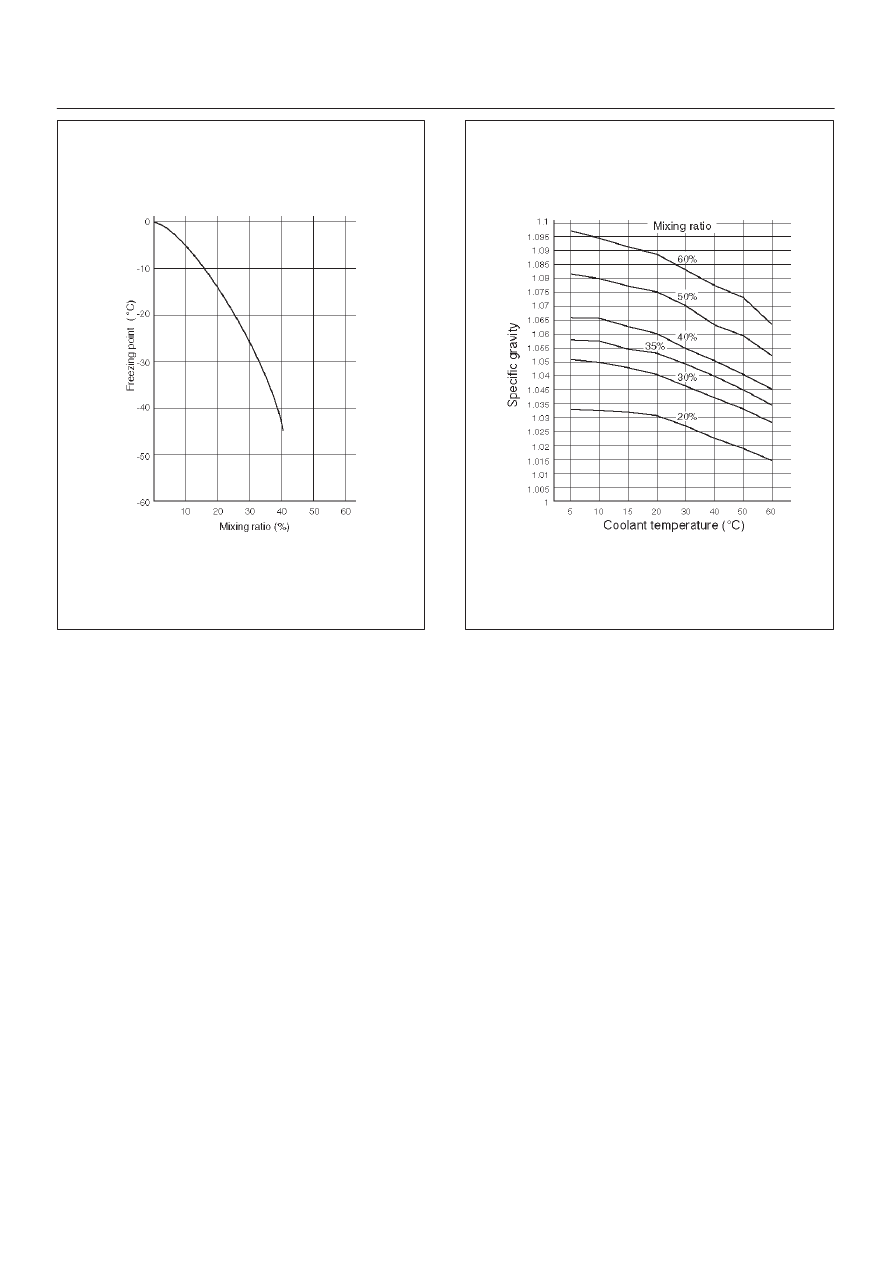

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system temperature ranges from 0

°

C to 50

°

C

using a suction type hydrometer, then determine the

density of the engine coolant by referring to the table.

NOTE:

1. Even in the areas where the atmospheric

temperature is higher than 0

°

C, be sure not to use

antifreeze solution at a mixing ratio lower than 20% so

that the inside of the engine may not be corroded.

2. If antifreeze solution is used at a mixing ratio higher

than 60%, the specific heat of the coolant falls and the

engine may be overheated. Moreover, antifreeze

performance drop and the coolant may be frozen.

The density of the solution must be adjusted as

occasion calls.

Antifreeze solution lower than 20% may not have

sufficient anticorrosive performance, and therefore,

please never fail to adjust as occasion demands within

the range of 20% to 60%.

B06RW003