Opel Frontera UE. Manual - part 882

6A–77

ENGINE MECHANICAL (6VD1 3.2L)

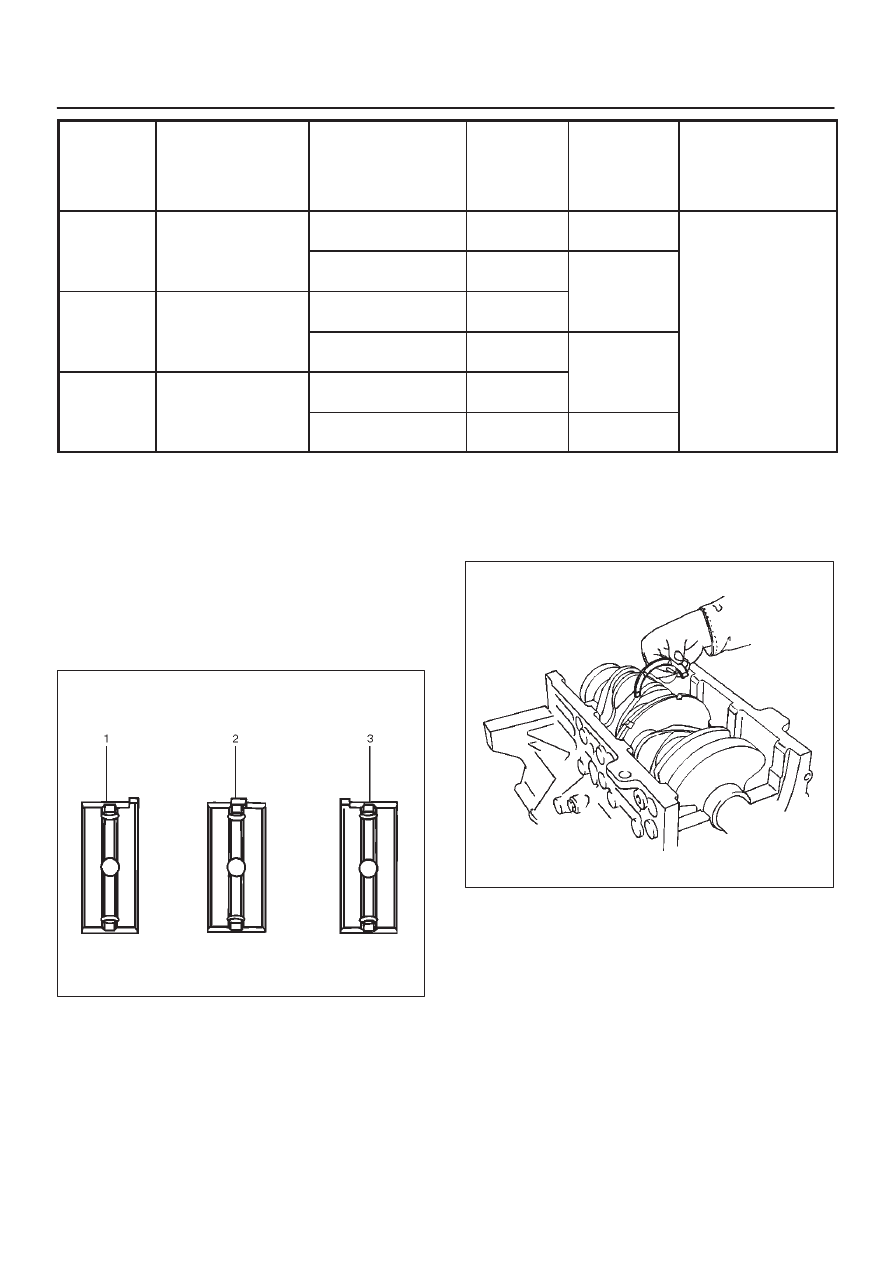

Main

Bearing

Grade Mark

On Cylinder

Block

Main Bearing Bore

Diameter

mm (in)

Crank Shaft Main

Journal Diameter

mm (in)

Crankshaft

Bearing

Grade Mark

On

Crankshaft

Crankshaft

Bearing Size

Mark (collor

indicator)

Oil Clearance

(Reference)

mm (in)

1

68.994-69.000

63.918-63.925

(2.5165-2.5167)

2

Blue

1

(2.7163-2.7165)

63.926-63.933

(2.5168-2.5170)

1

Brown

2

68.987-68.993

63.918-63.925

(2.5165-2.5167)

2

Brown

0.019–0.043

2

(2.7160-2.7163)

63.926-63.933

(2.5168-2.5170)

1

Green

(0.0007–0.0017)

3

68.980-68.986

63.918-63.925

(2.5165-2.5167)

2

Green

3

(2.7157-2.7160)

63.926-63.933

(2.5168-2.5170)

1

Yellow

Reassembly

1. Crankshaft

D

Install the main bearings to the cylinder block and

the main bearing caps.

D

Be sure that they are positioned correctly.

D

Apply new engine oil to the upper and lower main

bearing faces.

NOTE: Do not apply engine oil to the main bearing back

faces.

015RS012

D

Carefully mount the crankshaft.

D

Apply engine oil to the thrust washer.

D

Assemble the thrust washer to the No.3 bearing

journal. The oil grooves must face the crankshaft.

015R100033

2. Rear oil seal

D

Remove the oil from the cylinder block and the

retainer mounting surface.

D

Apply sealant (TB–1207B or equivalent) to the

retainer mounting surface, following the pattern

shown in the illustration.

The retainer must be installed within 5 minutes

after sealant application befor the sealant hardens.