Opel Frontera UE. Manual - part 817

6E1–151

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

2. If the conditions for the test as described above are

met, a Diagnostic Trouble Code P0325 will set and

MIL will illuminate.

4. If the engine has an internal knock or audible noise

that causes a knocking type noise on the engine

block, the knock sensor may be responding to the

noise.

6. The Tech 2 displays knock sensor activity in counts,

approximately 20–50 at idle. The counts should

increase when engine speed is increased and the

counts should decrease when engine speed is

decreased.

7. Any circuitry, that is suspected as causing the

complaint, should be thoroughly checked for backed

out terminals, improper mating, broken locks,

improperly formed or damaged terminals, poor

terminal to wiring connections or physical damage

to the wiring harness.

8. If the KS module was previously replaced and the

Diagnostic Trouble Code resets, a malfunctioning

ECM is indicated.

9. Checking the internal resistance of the knock sensor

verifies if the knock sensor or the wiring to the

knock sensor is OK.

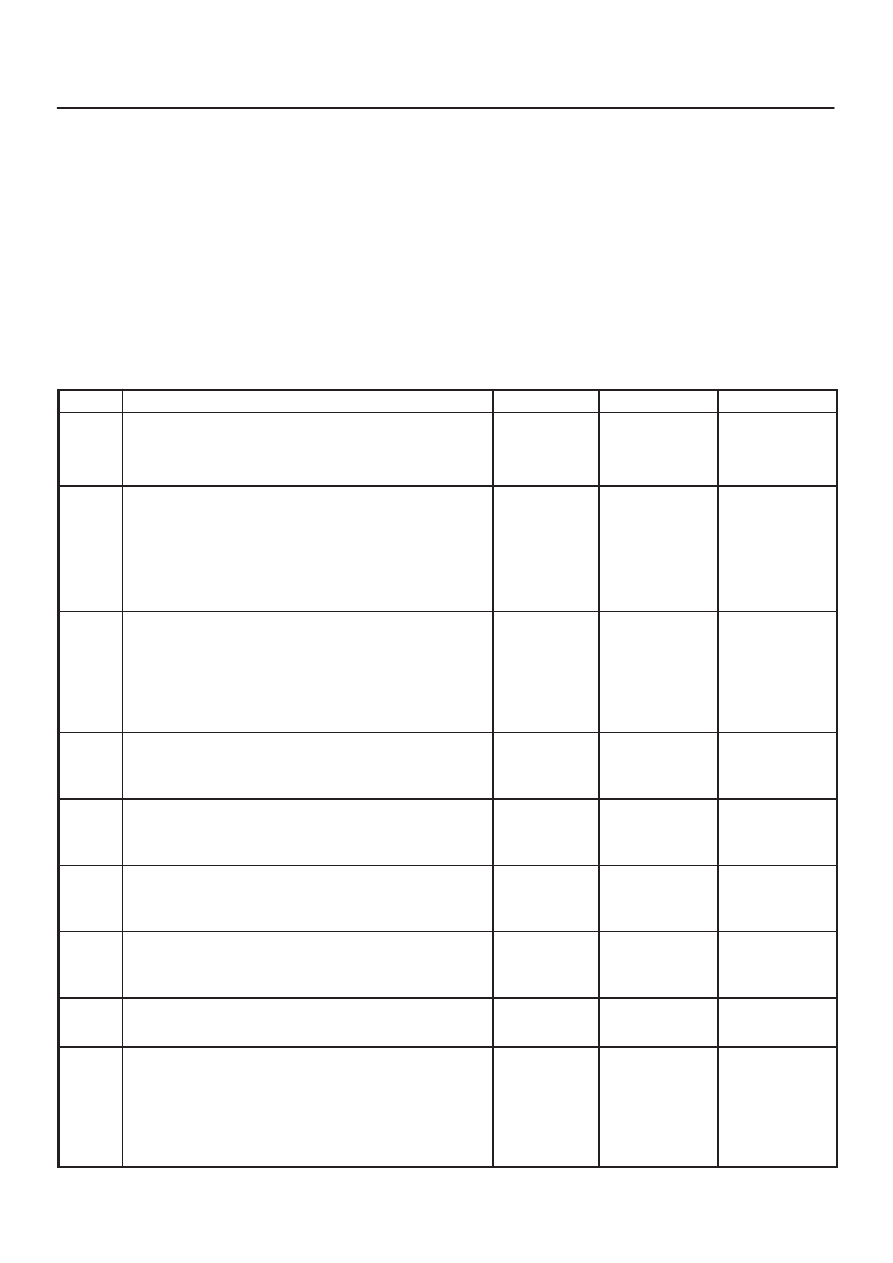

DTC P0325 KS Circuit Malfunction

Step

Action

Value(s)

Yes

No

1

Was the Powertrain ”On–Board Diagnostic (OBD)

System Check” performed?

—

—

Go to Step 2

Go to

Powertrain

OBD System

Check

2

1. Start the engine.

2. Install a Tech 2.

3. Clear the Diagnostic Trouble Codes.

4. Run the engine at slightly more than 10% throttle

angle.

Does the Malfunction Indicator Lamp (MIL) illuminate?

—

Go to Step 4

Go to Step 3

3

1. Turn the ignition switch ON, with engine OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Conditions and

Conditions for Setting the DTC as noted.

Does the Malfunction Indicator Lamp (MIL) illuminate?

—

Go to Step 4

Go to Step

13

4

Listen to the engine while raising and lowering the

engine speed.

Is a knock or audible noise present?

—

Go to Step 5

Go to Step 6

5

Repair the mechanical engine problem or a loose

bracket or component.

Is the action complete?

—

Go to Step

13

—

6

Slowly increase the engine speed to the specified

value.

Does the KS Activity increase with the engine speed?

2500 RPM

Go to Step 7

Go to Step

11

7

Check for a poor connection at the ECM connector,

Knock sensor signal circuit and repair as necessary.

Was a repair necessary?

—

Go to Step

13

Go to Step 8

8

Replace the ECM.

Is the action complete?

—

Go to Step

13

—

9

1. Turn the ignition switch OFF.

2. Disconnect the ECM connectors at the ECM.

3. With a Digital Voltmeter (DVM) connected to

ground, measure the resistance of the knock

sensor through the knock sensor signal circuit.

Is the measured value within the specified value?

90K – 110K

W

Go to Step 7

Go to Step

10