Opel Frontera UE. Manual - part 811

6E1–127

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

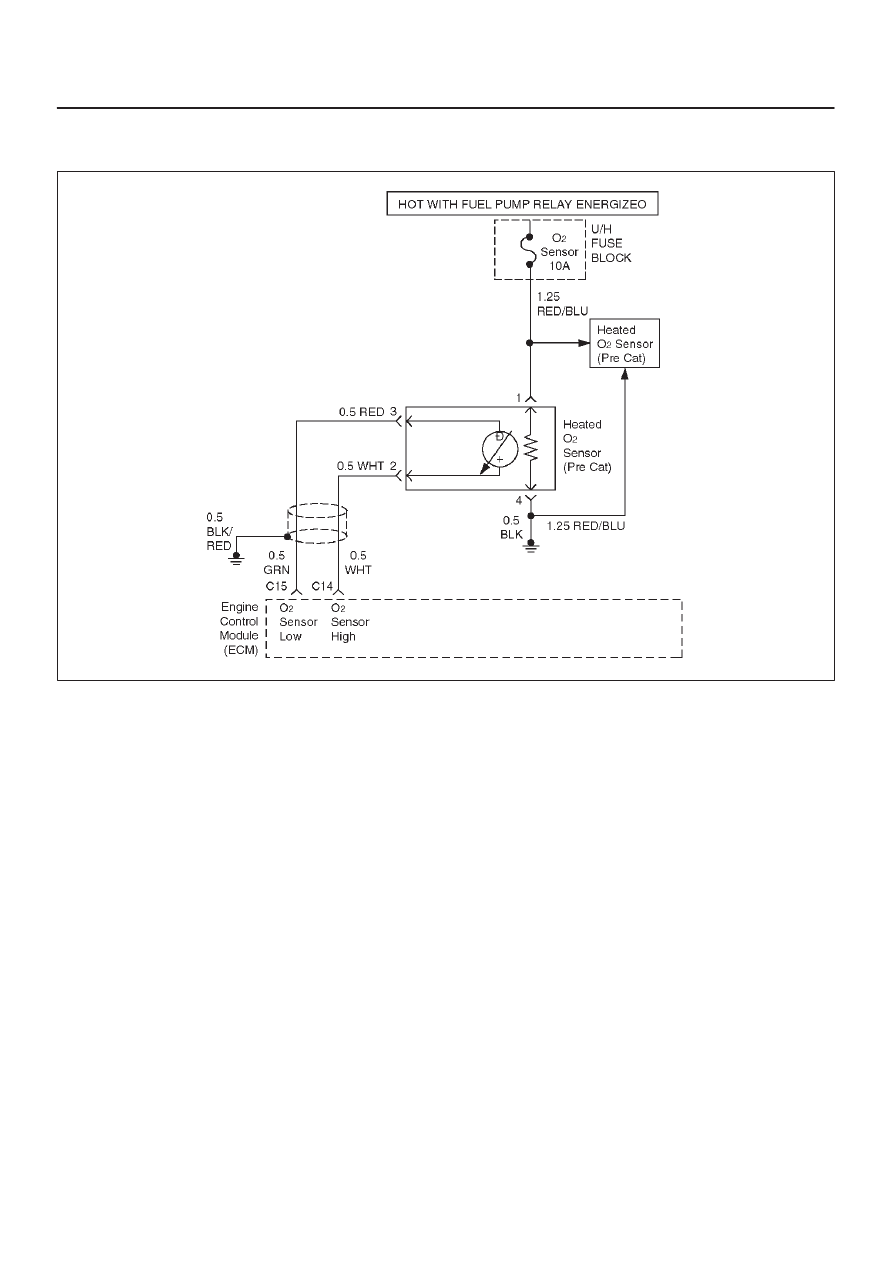

DIAGNOSTIC TROUBLE CODE (DTC) P0135 O2 SENSOR HEATER CIRCUIT

MALFUNCTION

D06RX119

Circuit Description

Heated oxygen sensors are used to minimize the amount

of time required for “Closed Loop” fuel control operation

and to allow accurate catalyst monitoring. The oxygen

sensor heater greatly decreases the amount of time

required for fuel control sensors Bank 1 HO2S 1.

The engine control module (ECM) will run the heater test

only after a cold start (determined by engine coolant and

intake air temperature at the time of start–up) and only

once during an ignition cycle. When the engine is started

the ECM will monitor the HO2S voltage. When the HO2S

voltage indicates a sufficiently active sensor, the ECM

looks at how much time has elapsed since start–up. If the

ECM determines that too much time was required for the

Bank 1 HO2S 1 to become active, a Diagnostic Trouble

Code P0135 will set. DTC P0135 is a type B code.

Conditions for Setting the DTC

D

No related Diagnostic Trouble Codes.

D

Intake air temperature (IAT) is less than 32

°

C (90

°

F)

at start–up.

D

Engine coolant temperature (ECT) is less than 32

°

C

(90

°

F) at start–up.

D

IAT and ECT are within 5

°

C (9

°

F) of each other at

start–up.

D

Ignition voltage is between 11 and 16.6 V.

D

Average calculated air flow is less than 18 g/second

during sample period.

D

Throttle angle is less than 40%.

D

Bank 1 HO2S 1 voltage does not change more than

148 mV from the bias voltage (between 400 mV and

500 mV) for a longer amount of time than it should. The

maximum amount of time to come up to operating

range is 240 seconds. This warm–up time depends on

the engine coolant temperature at start–up and intake

air temperature at start–up.

Action Taken When the DTC Sets

D

The ECM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

D

The ECM will store conditions which were present

when the Diagnostic Trouble Code was set as Freeze

Frame and in the Failure Records data.

Conditions for Clearing the MIL/DTC

D

The ECM will turn the MIL OFF on the third consecutive

trip cycle during which the diagnostic has been run and

the fault condition is no longer present.

D

A history Diagnostic Trouble Code P0135 will clear

after 40 consecutive warm–up cycles have occurred

without a fault.

D

Diagnostic Trouble Code P0135 can be cleared by

using the Scan Tool’s ”Clear Info” function.