Opel Frontera UE. Manual - part 802

6E1–91

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

DTC P0106 MAP Circuit/Range Performance Problem

(Cont'd)

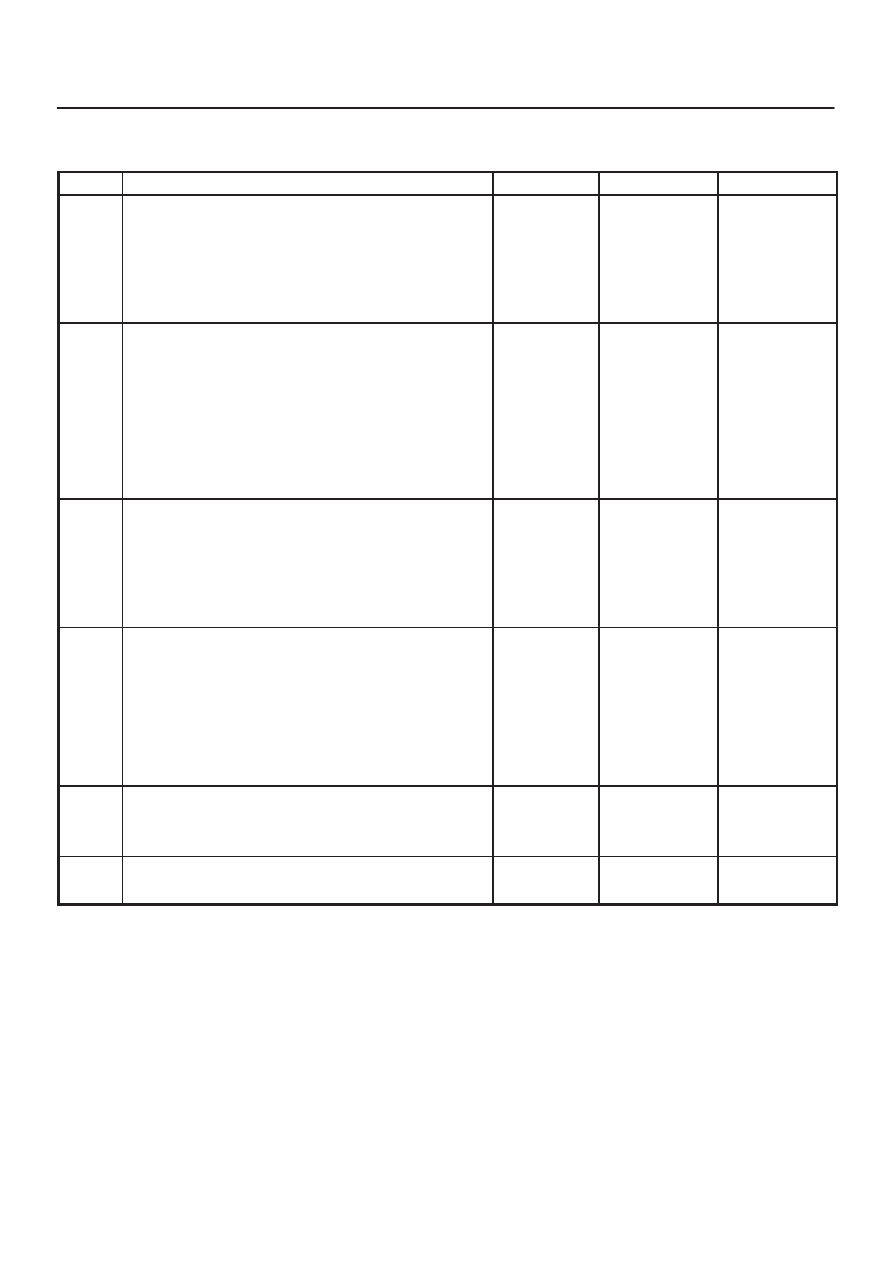

Step

No

Yes

Value(s)

Action

7

Check the 5 volt signal circuit, between the MAP

sensor and the ECM, for the following conditions:

D

An open circuit

D

A short to ground

D

A short to voltage

Was the problem found?

—

Verify repair

Go to Step 8

8

1. Ignition OFF.

2. Place a fused jumper between the MAP sensor

circuit and the 5 volt signal circuit, both at the wiring

harness’ MAP sensor connector.

3. Ignition ON, engine OFF.

4. Observe the MAP value displayed on the Tech 2?

Does the Tech 2 read the following value? (if no, start

with the diagnosis chart for other sensors in the circuit

and see if 5V returns.)

5 volts 104

kPa

Go to Step 9

Go to Step 12

9

Check the MAP sensor ground circuit, between the

MAP sensor and the ECM, for the following conditions:

D

An open circuit

D

A short to ground

D

A short to voltage

Was the problem found?

—

Verify repair

Go to Step 10

10

1. Ignition OFF.

2. Place a Digital Multimeter (DVM), set to measure

voltage, between the ground circuit and the 5 volt

signal circuit, both at the wiring harness’ MAP

sensor connector.

3. Ignition ON, engine OFF.

5 volts

Does the DVM read the following value?

—

Go to Step 11

Go to Step 12

11

Replace the MAP sensor.

Verify repair.

—

—

—

12

Replace the ECM.

—

—

—