Opel Frontera UE. Manual - part 775

IGNITION SYSTEM (X22SE 2.2L)

6D2–3

Possible causes:

• Too lean mixture

• Improper heat value

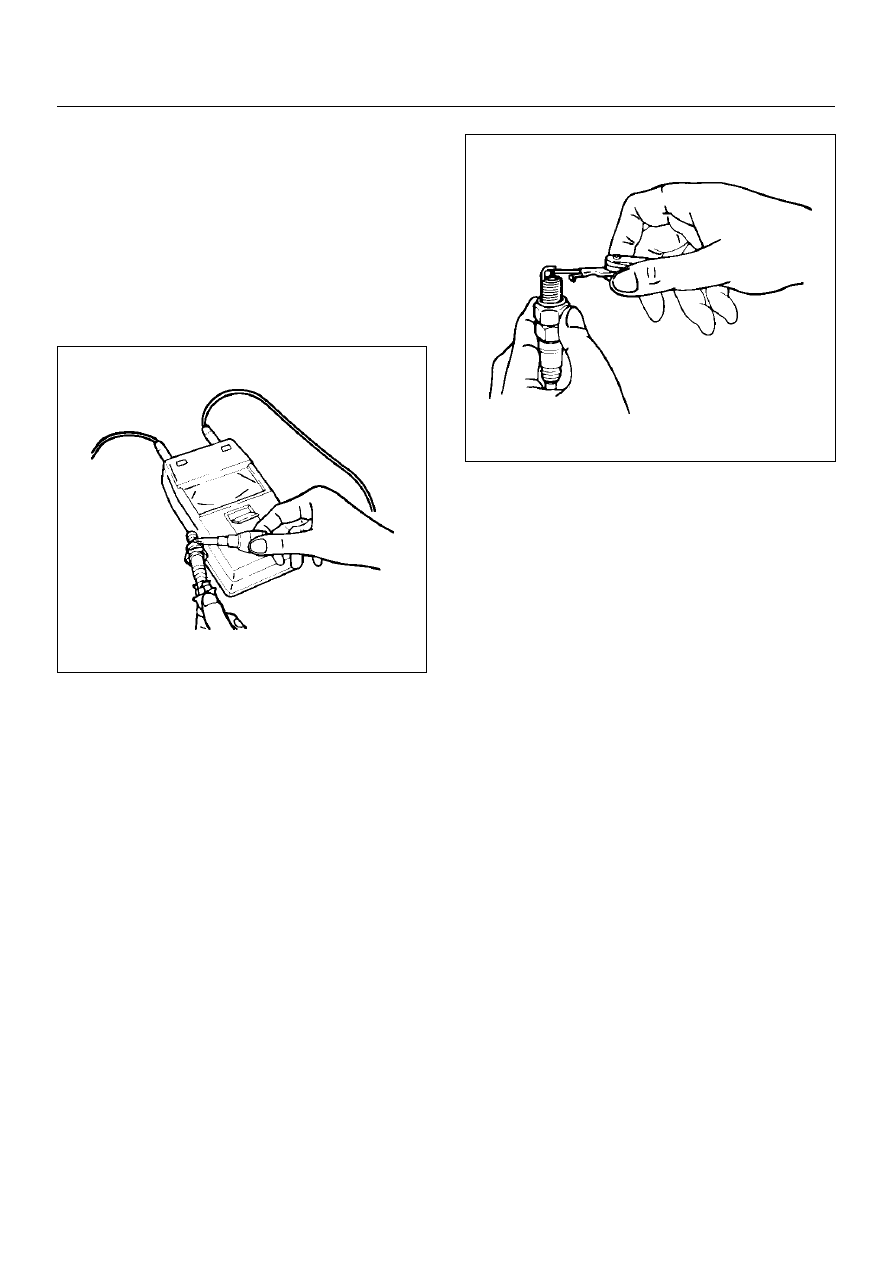

Measuring Insulation Resistance

• Measure insulation resistance using a 500 volt

megaohm meter.

• Replace spark plugs if measured value is out of

standard.

Insulation resistance: 50 M

Ω

Ω

Ω

Ω

or more

011RS010

Cleaning Spark Plugs

• Clean spark plugs with a spark plug cleaner.

• Raise the ground electrode to an angle of 45 to 60

degrees. if electrode is wet,dry it before cleaning.

• After spark plug is thoroughly cleaned,check insulator

for presence of cracks.

• Clean threads and metal body with a wire brush.

• File the electrode tip if electrode is extremely worn.

• Bend the ground electrode to adjust the spark plug

gap.

011RS011

Installation

1. Spark plugs

• Tighten spark plugs to the specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb ft)