Opel Frontera UE. Manual - part 771

ENGINE FUEL (X22SE 2.2L)

6C–5

Inspection

After installation, start engine and check for fuel leak

age.

In–Tank Fuel Filter

The filter is located on the lower end of the fuel pickup

tube in the fuel tank. It prevents dirt from entering the

fuel pipe and also stops water unless the filter is

completely submerged in the water. It is a self cleaning

type, not requiring scheduled maintenance. Excess

water and sediment in the tank restricts fuel supply to

the engine, resulting in engine stop. In such a case, the

tank must be cleaned throughly.

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks.

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe

and hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3. Insert the hose from fuel feed pipe into a clean

container, and check for fuel pump flow rate.

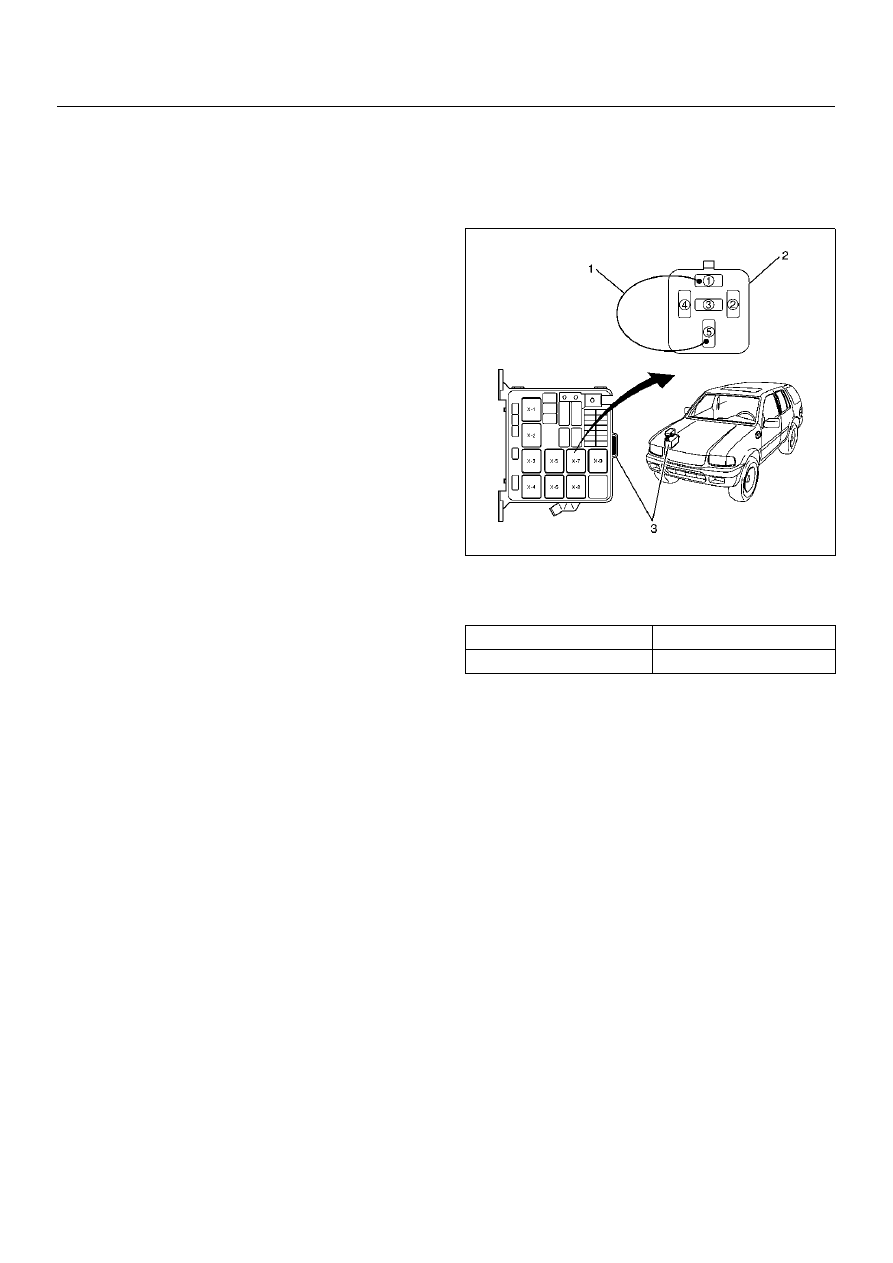

4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to

measure delivery.

140RW015

CAUTION: Never generate sparks when connecting

a jumper wire.

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System".

Delivery

Delivery

15 seconds

0.38 liters minimum