Opel Frontera UE. Manual - part 243

6E1–270

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

Engine Control Module (ECM)

Electrostatic Discharge (ESD)

Damage

Electronic components used in the control system are

often designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to same electronic

components. By comparison, it takes as much as 4000

volts for a person to even feel the zap of a static

discharge. There are several way for a person to become

statically charged. The most common methods of

charging are by friction and by induction. An example of

charging by friction is a person sliding across a car seat.

Charging by induction occurs when a person with well

insulated shoes stands near a highly charged object and

momentarily touches ground. Charge of the same polarity

are drained off leaving the person highly charged with

opposite polarity. Static charge can cause damage,

therefore, it is important to use care when handling and

testing electronic components.

NOTE: To prevent possible Electrostatic Discharge

damage, follow these guidelines:

D

Do not touch the control module connector pins or

soldered components on the control module circuit

board.

D

Do not open the replacement part package until the

part is ready to be installed.

D

Before removing the parts from the package, ground

the package to a known good ground on the vehicle.

D

If the parts been handled while sliding across the

seat, or while sitting from standing position, or walking

a distance, touch a known good ground before

installing the parts.

014RX002

NOTE: To prevent internal ECM damage, the ignition

must be OFF position in order to disconnect or reconnect

power to the ECM (for example: battery cable. pig tail,

ECM fuse, jumper cable, etc.).

IMPORTANT:

When replacing the production ECM

with a service ECM, it is important to transfer the

broadcast code and production ECM number to the

service ECM label. This will allow positive identification of

ECM parts throughout the service life of the vehicle. Do

not record this information on ECM metal cover.

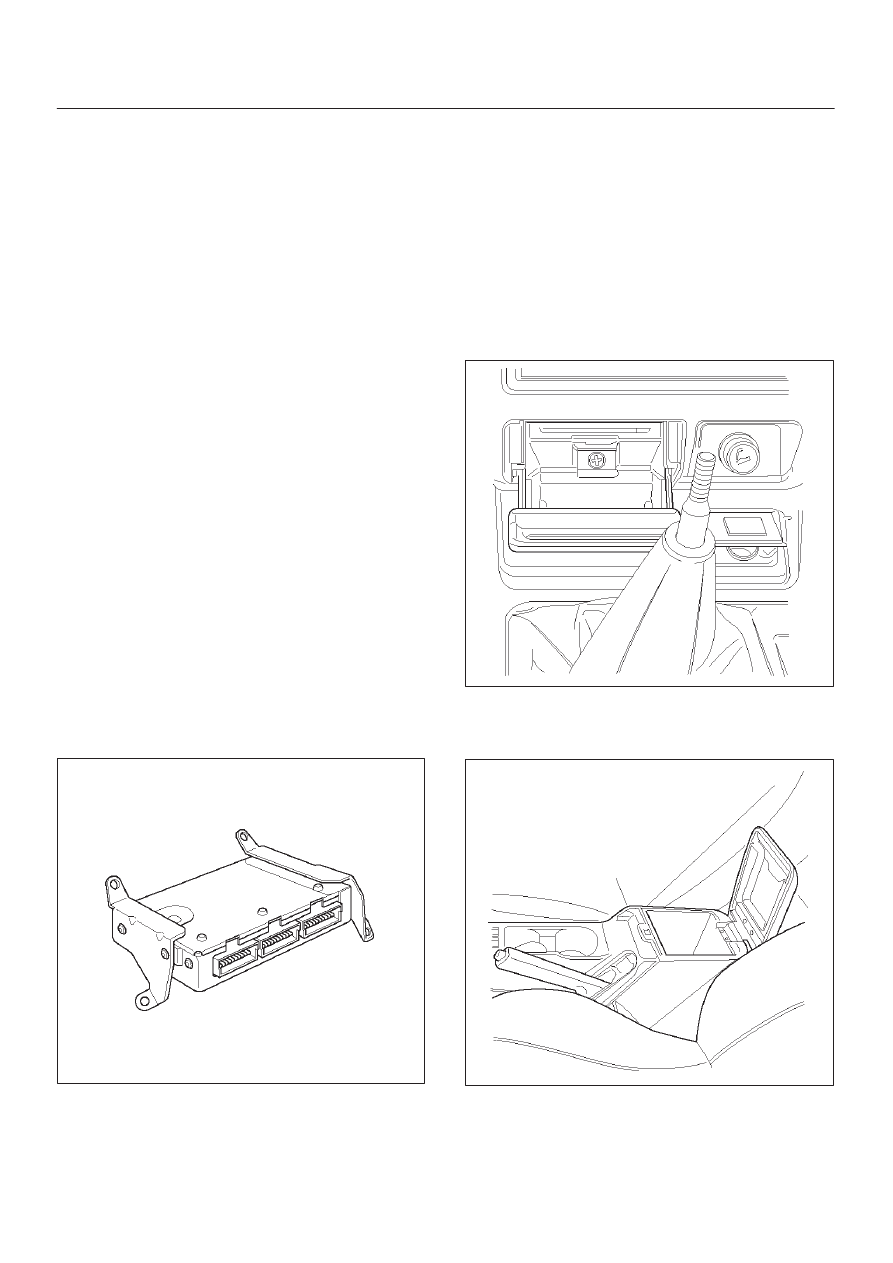

Removal Procedure

1. Disconnect the negative battery cable.

2. Block the wheels.

3. Remove ashtray inner.

4. Remove a screw located behind ashtray.

014RX014

5. Pull out Face trim of console.

6. Remove two screws located inside of center console

storage box and pull up rear part of center console.

014RX015

7. Unscrew the shift knob.

8. Remove four screw holding front part of the console

and pull the console up.