Opel Frontera UE. Manual - part 208

6E1–130

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

DIAGNOSTIC TROUBLE CODE (DTC) P0171 SYSTEM TOO LEAN (BANK 1)

D06RX119

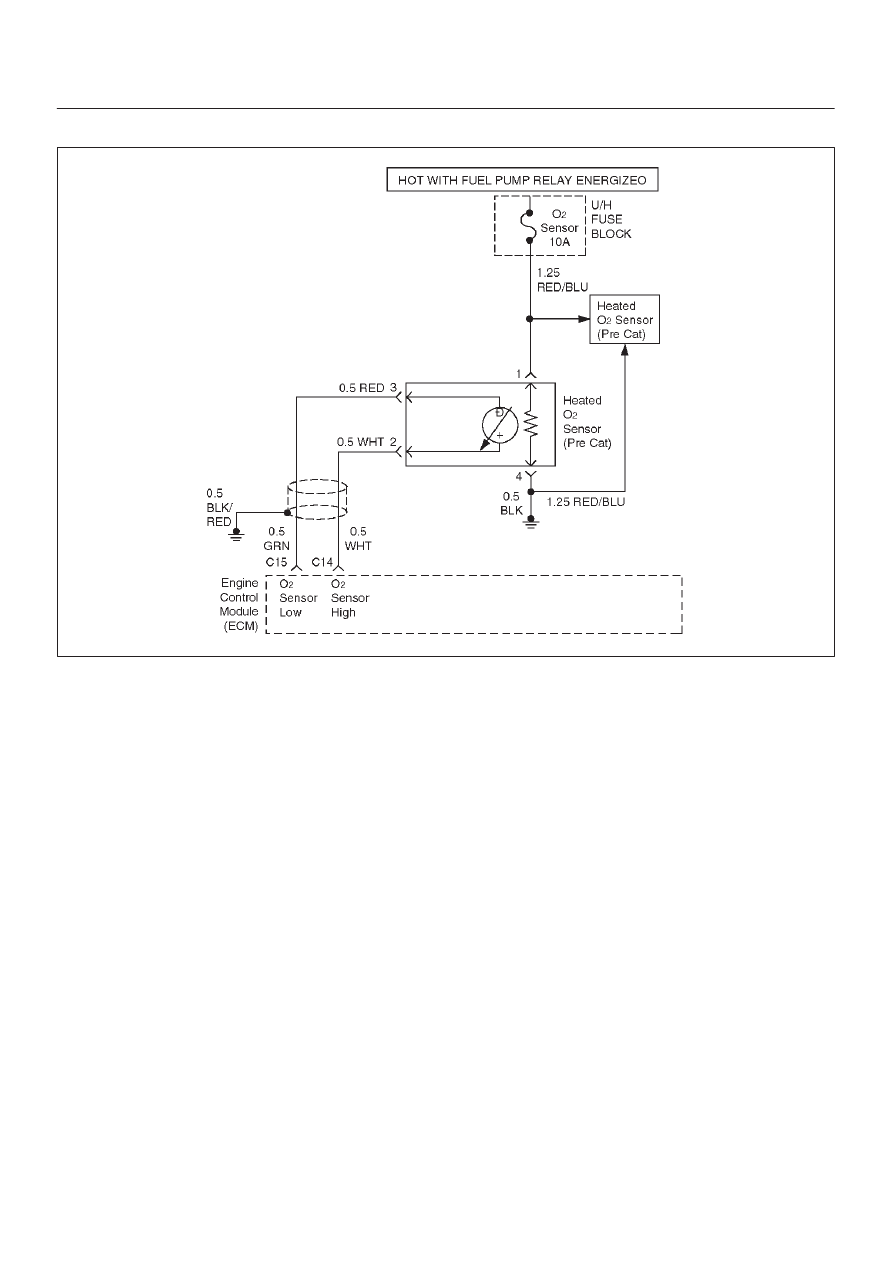

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a ”Closed Loop”

air/fuel metering system is used. While in ”Closed Loop”,

the engine control module (ECM) monitors the Bank 1

HO2S 1 signal and adjusts fuel delivery based upon the

HO2S signal voltage. A change made to fuel delivery will

be indicated by the long and short term fuel trim values

which can be monitored with a Tech 2. Ideal fuel trim

values are around 0%; if the HO2S signal indicates a lean

condition the ECM will add fuel, resulting in fuel trim

values above 0%. If a rich condition is detected, the fuel

trim values will be below 0%, indicating that the ECM is

reducing the amount of fuel delivered. If an excessively

lean condition is detected on Bank 1, the ECM will set

Diagnostic Trouble Code P0171. DTC P0171 is a type B

code.

The ECM’s maximum authority to control long term fuel

trim allows a range between –14% and +20%. The ECM

monitors fuel trim under various engine speed/load fuel

trim cells before determining the status of the fuel trim

diagnostic.

Conditions for Setting the DTC

D

No Tech 2 test is being run.

D

None of the following: EGR Diagnostic Trouble Codes,

HO2S Diagnostic Trouble Codes, (response,

transition, open, low volts, no activity), TP sensor

Diagnostic Trouble Codes, MAP Diagnostic Trouble

Codes, IAT Diagnostic Trouble Codes, canister purge

Diagnostic Trouble Codes, EVAP Diagnostic Trouble

Codes, injector circuit Diagnostic Trouble Codes, or

misfire Diagnostic Trouble Codes.

D

Engine coolant temperature is between 65

°

C (149

°

F)

and 104

°

C (219

°

F).

D

Intake air temperature is between –40

°

C (–40

°

F) and

120

°

C (248

°

F).

D

Manifold absolute pressure is between 23.75 kPa and

99 kPa.

D

Engine speed is between 400 and 6000 RPM.

D

Barometric pressure is greater than 72.3 kPa.

D

System voltage is greater than 9.5v.

D

Engine is operating in ”Closed Loop”.

D

The average of the short term fuel trim samples is

greater than 0.97 and the average of adaptive index

multiplier samples is greater than 1.21.

Action Taken When the DTC Sets

D

The ECM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

D

The ECM will store conditions which were present

when the Diagnostic Trouble Code was set as Freeze

Frame and in the Failure Records data.