Opel Frontera UE. Manual - part 187

6E1–46

X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

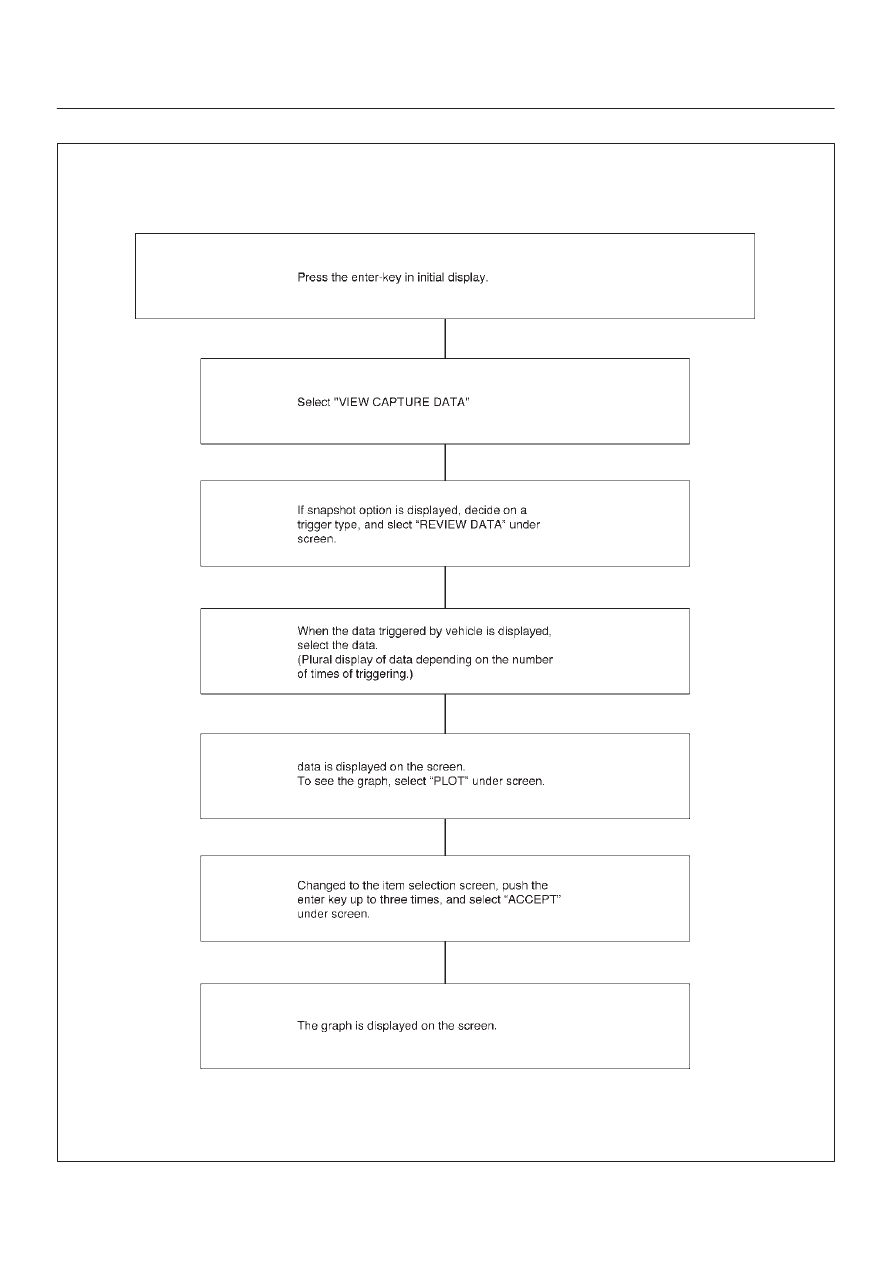

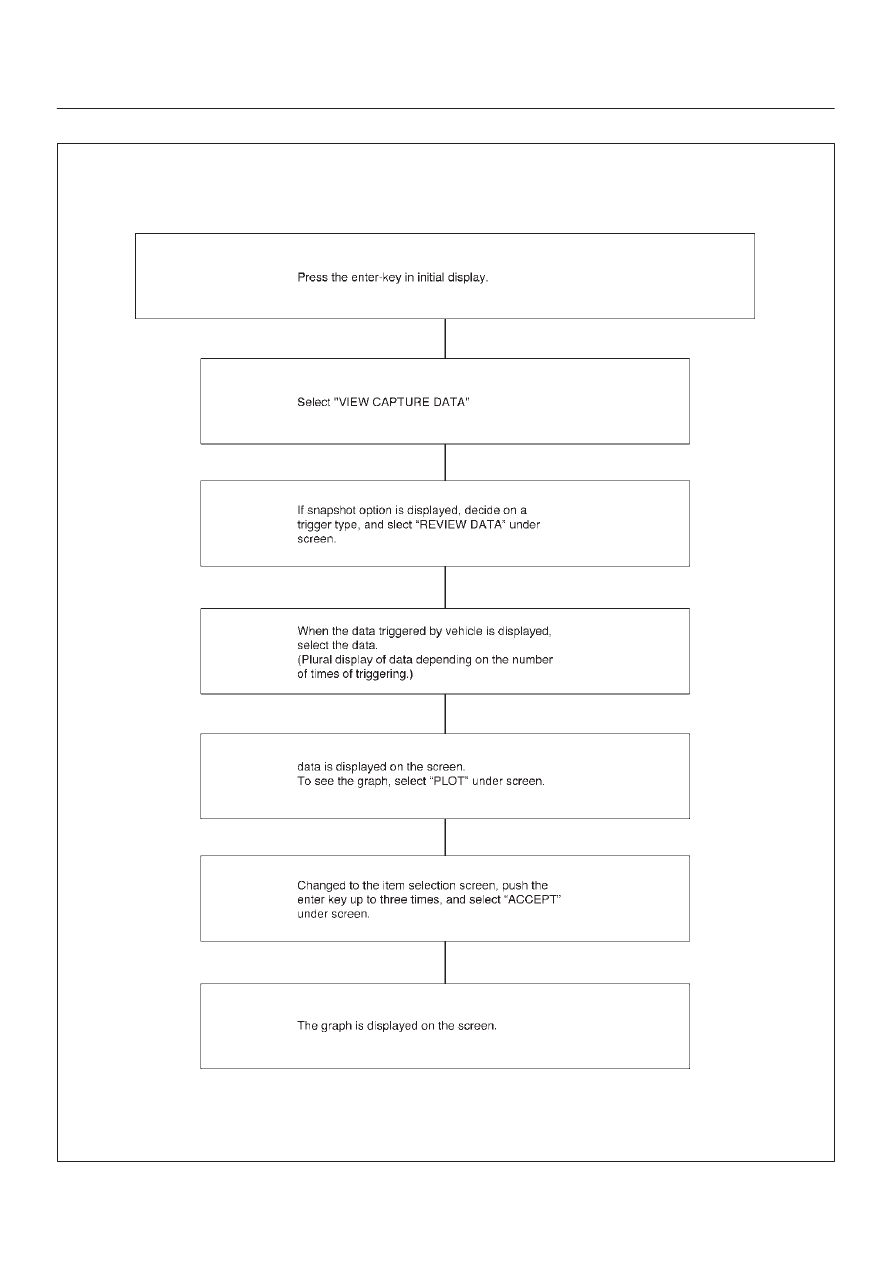

Flow Chart for Snapshot Replay (Plotting Graph)

060RX040

|

|

|

6E1–46 X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION Flow Chart for Snapshot Replay (Plotting Graph) 060RX040 |