Content .. 1750 1751 1752 1753 ..

Opel Frontera UE. Manual - part 1752

SUPPLEMENTAL RESTRAINT SYSTEM

9J–49

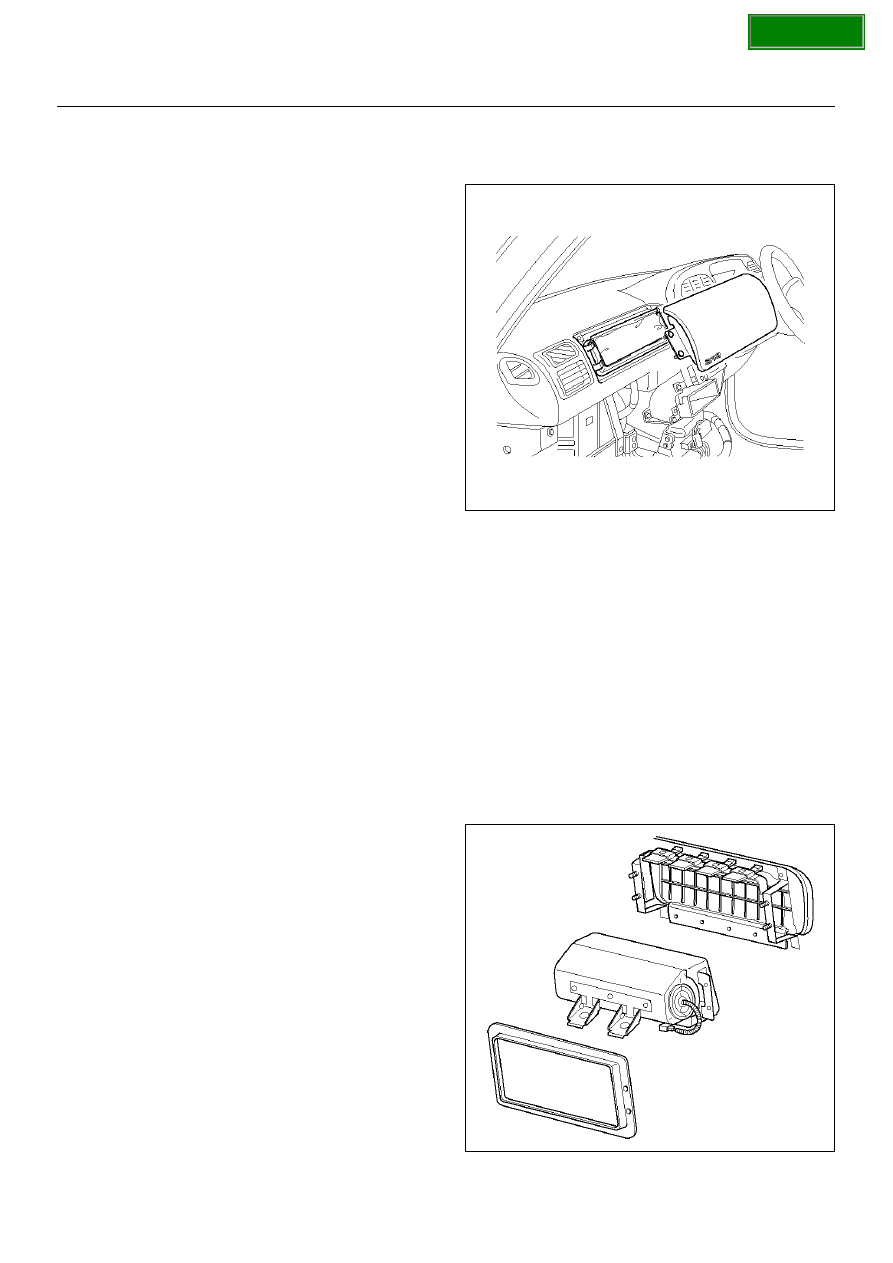

Passenger Air Bag Assembly

Service Precaution

WARNING: SAFETY PRECAUTIONS MUST BE

FOLLOWED WHEN HANDLING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE AIR

BAG ASSEMBLY SURFACE MAY CONTAIN A SMALL

AMOUNT OF SODIUM HYDROXIDE, A BY-PRODUCT

OF THE DEPLOYMENT REACTION, THAT IS

IRRITATING TO THE SKIN AND EYES. MOST OF THE

POWDER ON THE AIR BAG ASSEMBLY IS

HARMLESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH YOUR

HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG AND TRIM

COVER ARE POINTED AWAY FROM YOU. NEVER

CARRY AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE. IN

THE CASE OF AN ACCIDENTAL DEPLOYMENT, THE

BAG WILL THEN DEPLOY WITH MINIMAL CHANCE

OF INJURY. WHEN PLACING A LIVE AIR BAG

ASSEMBLY ON A BENCH OR OTHER SURFACE,

ALWAYS FACE BAG AND TRIM COVER UP, AWAY

FROM THE SURFACE. NEVER REST A STEERING

COLUMN ASSEMBLY ON THE STEERING WHEEL

WITH THE AIR BAG ASSEMBLY FACE DOWN AND

COLUMN VERTICAL. THIS IS NECESSARY SO THAT

A FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY COULD RESULT.

In the event deployment has occurred, inspect coil

assembly wire for any signs of scorching, melting or any

other damage due to excessive heat. If the coil has

been damaged, replace it.

Removal

1. Disable the SRS. (Refer to “Disabling the SRS" in

this section.)

2. Remove glove box assembly.

3. Disconnect passenger air bag assembly harness

connector.

4. Remove air bag assembly fixing bolts and nuts.

5. Remove reinforcement.

6. Remove passenger air bag assembly from glove

box opening of instrument panel.

827RX051

Installation

1. Install passenger air bag assembly from glove box

opening of instrument panel.

2. Install reinforcement from glove box opening of

instrument panel.

3. Install air bag assembly fixing nuts and bolts, and

tighten to specified torque.

Torque: 7.8 N·m (69 lbin)

4. Connect air bag assembly harness connector.

5. Install glove box assembly.

6. Enable the SRS (Refer to “Enabling the SRS" in this

section.)

827RW062