Content .. 1743 1744 1745 1746 ..

Opel Frontera UE. Manual - part 1745

SUPPLEMENTAL RESTRAINT SYSTEM

9J–21

827RW050

Legend

EndOFCallout

9. Notify all people in the immediate area of your

intention to deploy the passenger air bag assembly.

The deployment will be accompanied by a

substantial noise which may startle the uninformed.

WARNING: DEPLOYED HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE AIR BAG IS TO BE DEPLOYED.

THE AIR BAG ASSEMBLY WILL IMMEDIATELY

DEPLOY THE AIR BAG WHEN A CONNECTING THE

DEPLOYMENT HARNESS TO THE POWER SOURCE

SHOULD ALWAYS BE THE LAST STEP IN THE AIR

BAG ASSEMBLY DEPLOYMENT PROCEDURE.

FAILURE TO FOLLOW PROCEDURES IN THE

ORDER LISTED MAY RESULT IN PERSONAL

INJURY.

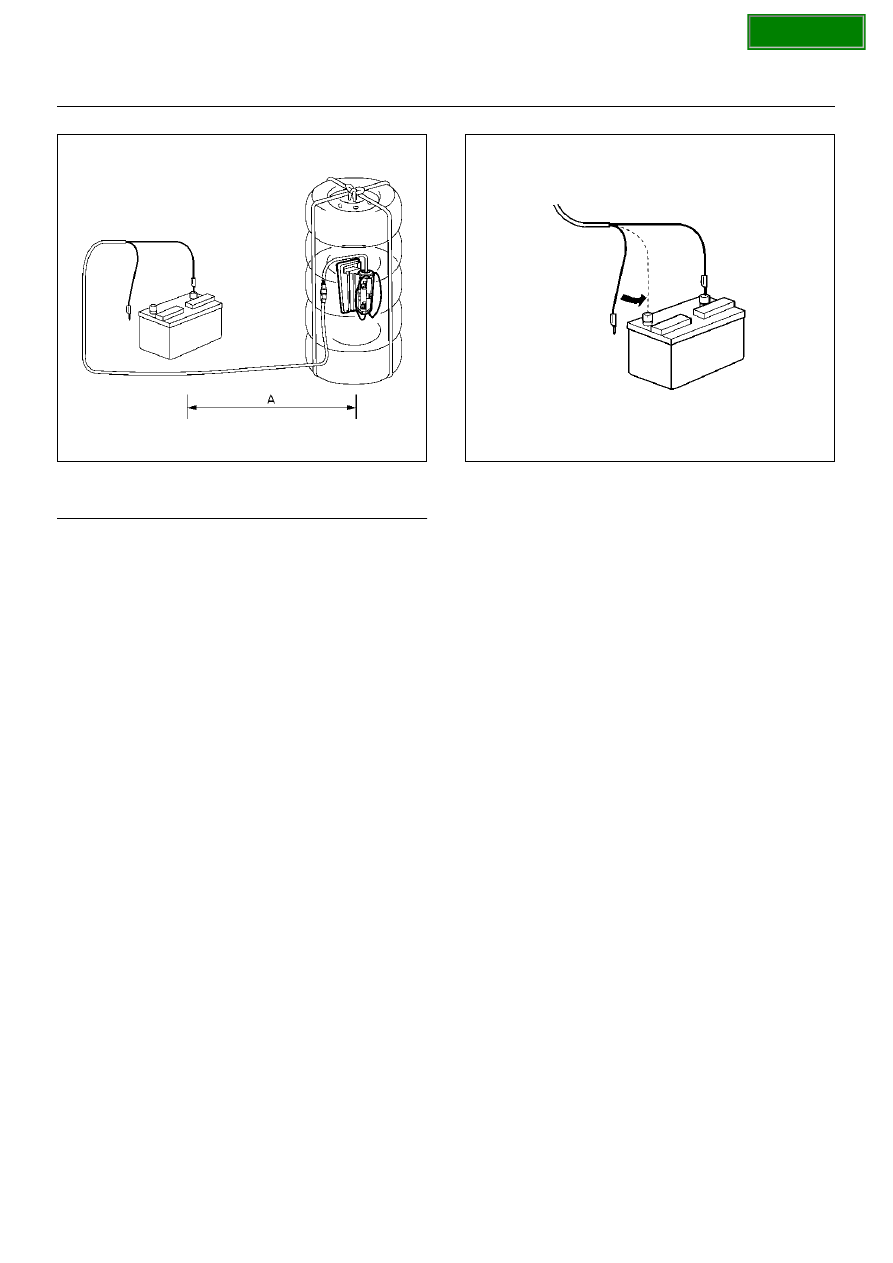

10. Connect the Supplemental Restraint System (SRS)

deployment harness wires to the power source to

immediately deploy the air bag assembly.

Recommended application : 12 volts minimum, 2

amps minimum. A vehicle battery is suggested.

827LW011

WARNING: SAFETY PRECAUTIONS MUST BE

OBSERVED WHEN HANDING A DEPLOYED AIR

BAG ASSEMBLY. AFTER DEPLOYMENT, THE METAL

SURFACES OF THE AIR BAG ASSEMBLY WILL BE

VERY HOT. ALLOW THE AIR BAG ASSEMBLY TO

COOL BEFORE HANDLING ANY METAL PORTION

OF IT. DO NOT PLACE THE DEPLOYED INFLATOR

MODULE NEAR ANY FLAMMABLE OBJECTS.

FAILURE TO FOLLOW PROCEDURES MAY RESULT

IN FIRE OR PERSONAL INJURY. AFTER AN AIR

BAG ASSEMBLY HAS BEEN DEPLOYED, THE

METAL CANISTER AND SURROUNDING AREAS OF

THE AIR BAG ASSEMBLY WILL BE HOT. DO NOT

TOUCH THE METAL AREAS OF THE AIR BAG

ASSEMBLY FOR ABOUT THIRTY MINUTES AFTER

DEPLOYMENT. IF THE DEPLOYED AIR BAG

ASSEMBLY MUST BE MOVED BEFORE IT IS COOL,

WEAR GLOVES AND HANDLE BY THE AIR BAG IT

SELF.

11. Disconnect the pigtail adapter from the air bag

assembly as soon after deployment as possible to

avoid damage to the pigtail adapter or SRS

deployment harness from contacting the hot air bag

assembly canister. The pigtail adapter and SRS

deployment harness are designed to be reused.

They should, however, be inspected for damage

after each deployment and replaced if necessary.

12. Dispose of the deployed air bag assembly through

normal refuse channels after it has cooled for at

least 30 minutes.

13. Wash your hands with mild soap and water

afterward.

NOTE: The remaining steps are to be followed in the

unlikely event that the air bag assembly did not deploy

after following the above procedures.

14. Ensure that the SRS deployment harness has been

disconnected from the power source and that its two

banana plugs have been shorted together by fully

(A) 10 m (33 feet) or more