Content .. 1550 1551 1552 1553 ..

Opel Frontera UE. Manual - part 1552

6E–423

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the IAT sensor into the grommet in the intake

air duct.

2. Correct the IAT electrical connector.

TS23741

3. Install the engine cover.

4. Connect the negative battery cable.

ION Sensing Module

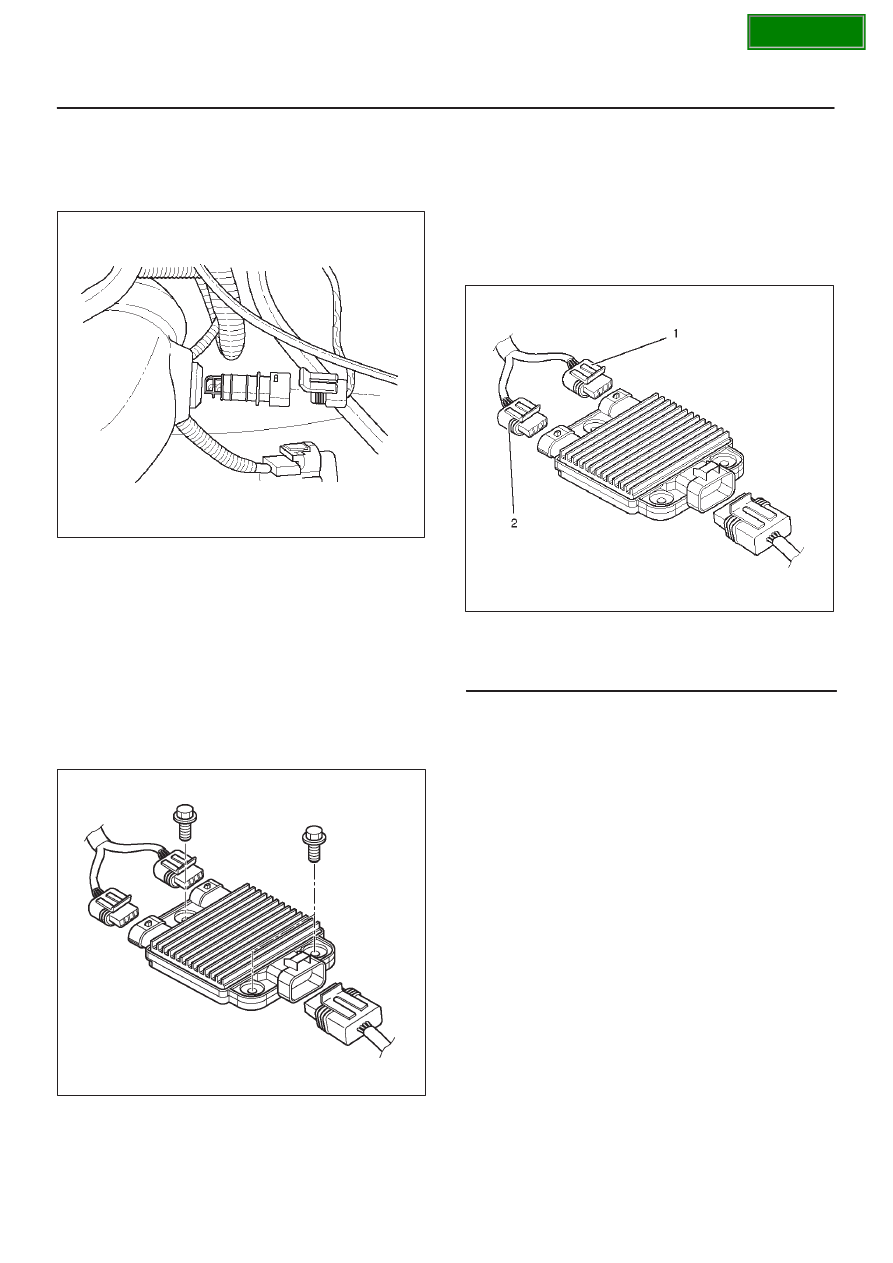

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the ION sensing module connector.

3. Remove the bolts and the ION sensing module from

the common chamber.

060R100143

Installation Procedure

1. Install the ION sensing module on the common

chamber with the bolts.

Tighten

D

Tighten the ION sensing module to 4 N·m (35 lb

in.).

2. Connect the ION sensing module connectors as

shown in the illustration.

060RY00003

Legend

(1) Green (Light Blue) Color Connector

(2) Blue Color Connector

3. Connect the negative battery cable.