Content .. 1519 1520 1521 1522 ..

Opel Frontera UE. Manual - part 1521

6E–299

6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

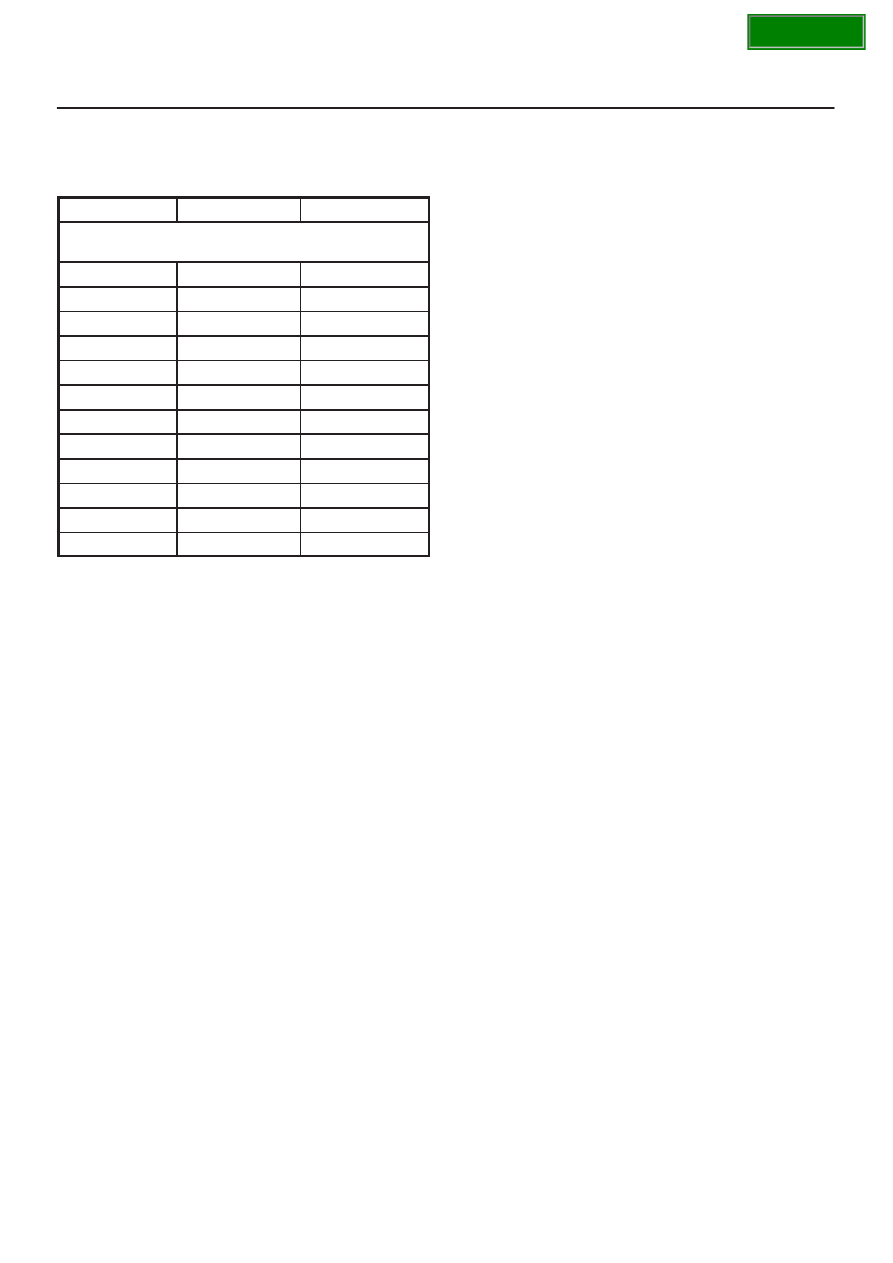

Engine Coolant Temperature Sensor

°

C

°

F

OHMS

Temperature vs. Resistance Values

(approximate)

100

212

177

80

176

332

60

140

667

45

113

1188

35

95

1802

25

77

2796

15

59

4450

5

41

7280

–5

23

12300

–15

5

21450

–30

–22

52700

–40

–40

100700