Content .. 1420 1421 1422 1423 ..

Opel Frontera UE. Manual - part 1422

6A–65

ENGINE MECHANICAL (6VD1 3.2L)

Camshaft

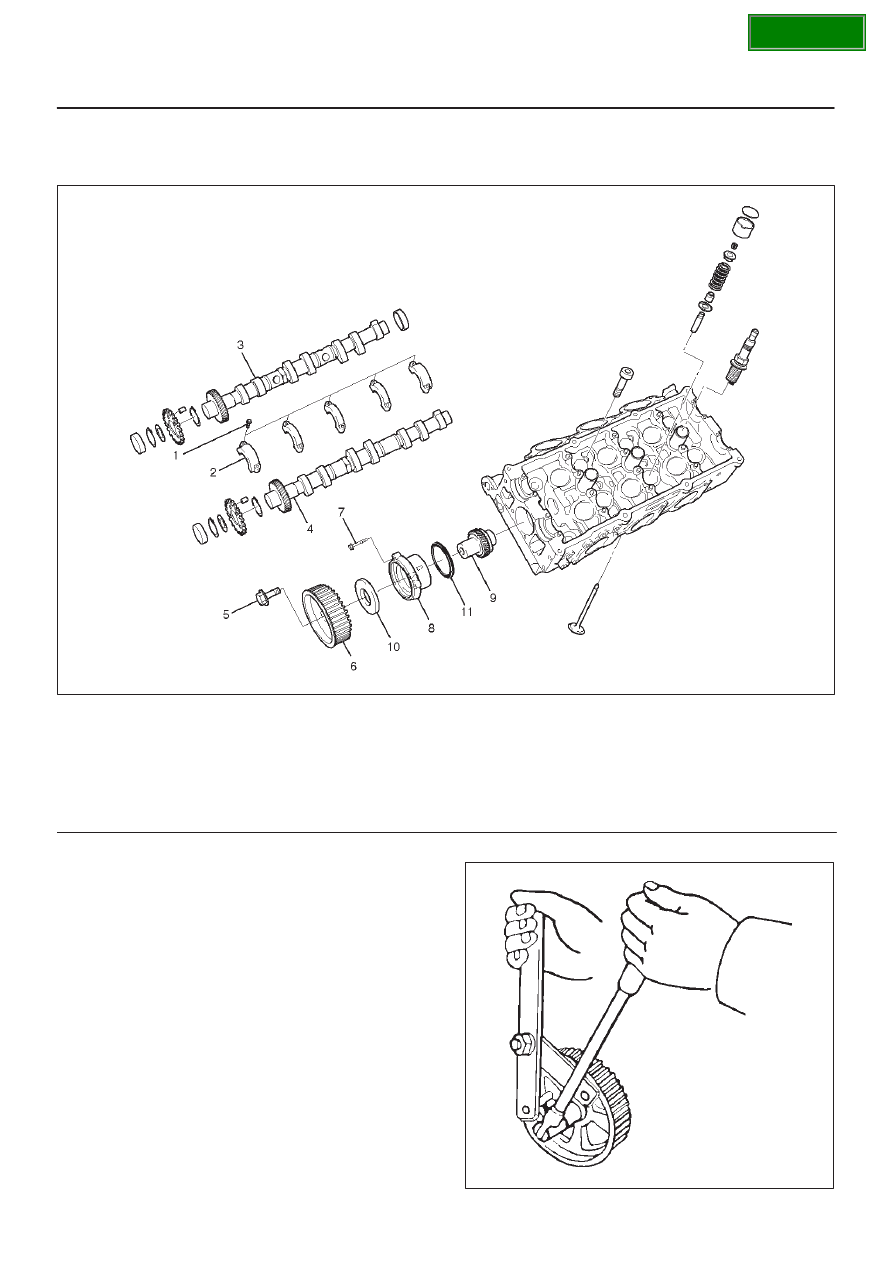

Camshaft and Associated Parts

014R100028

Legend

(1) Camshaft Bracket Fixing Bolt

(2) Camshaft Bracket

(3) Camshaft Assembly Intake

(4) Camshaft Assembly Exhaust

(5) Pulley Fixing Bolt

(6) Camshaft Drive Gear Pulley

(7) Retainer Fixing Bolt

(8) Retainer

(9) Camshaft Drive Gear

(10) Oil Seal

(11) O–ring

Disassembly

1. Remove fixing bolt (5) for camshaft drive gear pulley

using the 5–8840–2447–0 universal holder.

014RW060