Content .. 1361 1362 1363 1364 ..

Opel Frontera UE. Manual - part 1363

4D1–28 TRANSFER CASE

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

D

Teeth for wear, scuffs, nicks, burrs or breaks.

D

Keys and springs for wear, cracks or distortion,

replace if these conditions are present.

D

If scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

Block Ring and Insert Clearance

1. Use a vernier caliper to measure the clearance

between the block ring and the insert.

2. If the measured value exceeds the specified limit, the

block ring and the insert must be replaced.

Block ring and insert clearance

Standard : 2.46–2.74 mm (0.097–0.108 in)

Limit : 3.0 mm (0.118 in)

226RS037

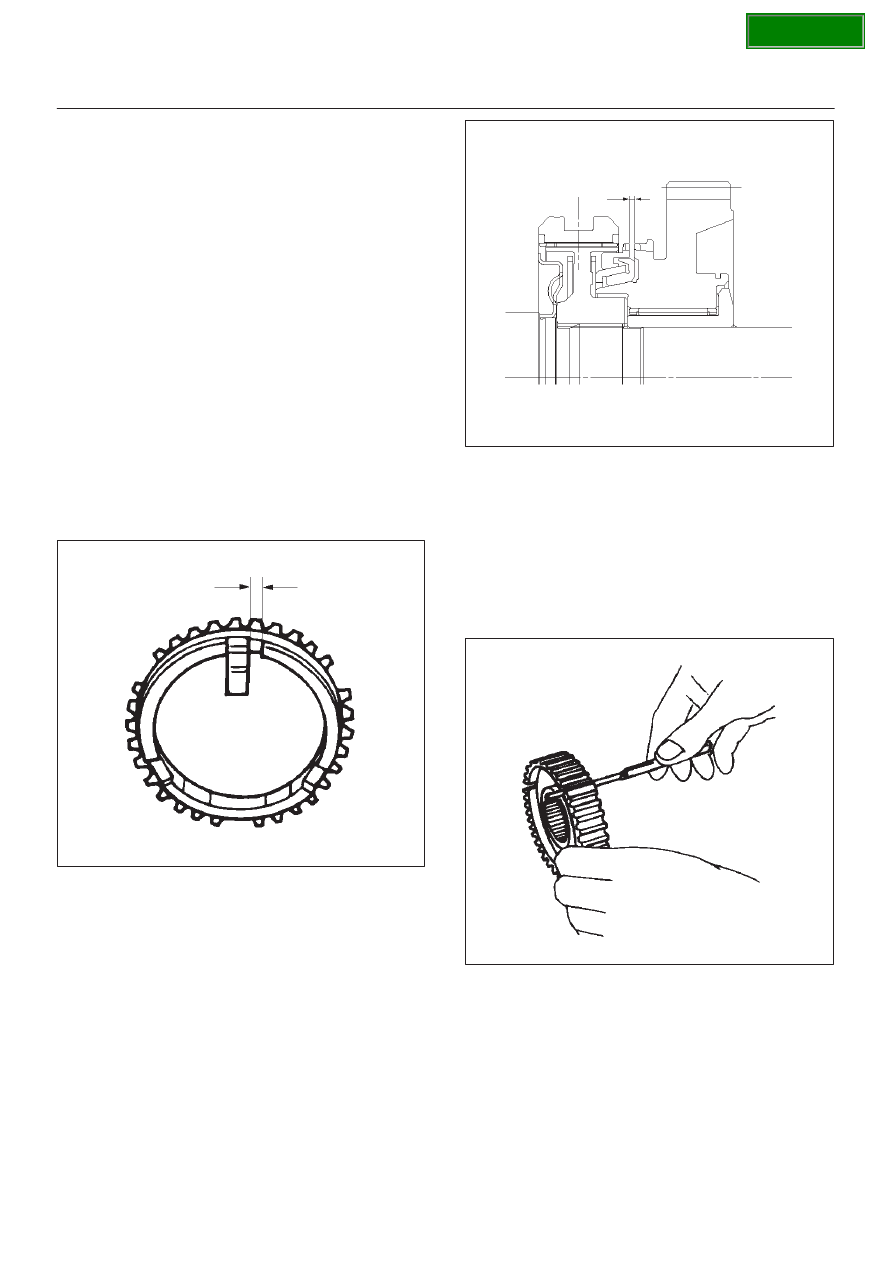

2WD–4WD Synchronizer (3–Cone)

1. Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

2. If the measured value exceeds the specified limit, the

2WD–4WD synchronizer assembly must be

replaced.

Block ring and insert clearance

Standard : 1.5 mm (0.059 in)

Limit : 0.8 mm (0.031 in)

226RW142

Clutch Hub and Insert Clearance

1. Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

2. If the measured value exceeds the specified limit, the

clutch hub and the insert must be replaced.

Clutch hub and insert clearance

Standard : 0.01–0.19 mm (0.0004–0.0075 in)

Limit : 0.3 mm (0.012 in)

226RS038