Content .. 1360 1361 1362 1363 ..

Opel Frontera UE. Manual - part 1362

4D1–24 TRANSFER CASE

(32) Bearing Snap Ring

(33) Counter Gear Assembly

(34) Snap Ring

(35) Ball Bearing

(36) Snap Ring

(37) Ball Bearing

(38) Spacer

(39) Belleville Spring

(40) Sub–Gear (anti–lash plate)

(41) Counter Gear

(42) Transfer Case (with oil seal)

Disassembly

1. Use a pair of snap ring pliers to remove the snap ring

(1).

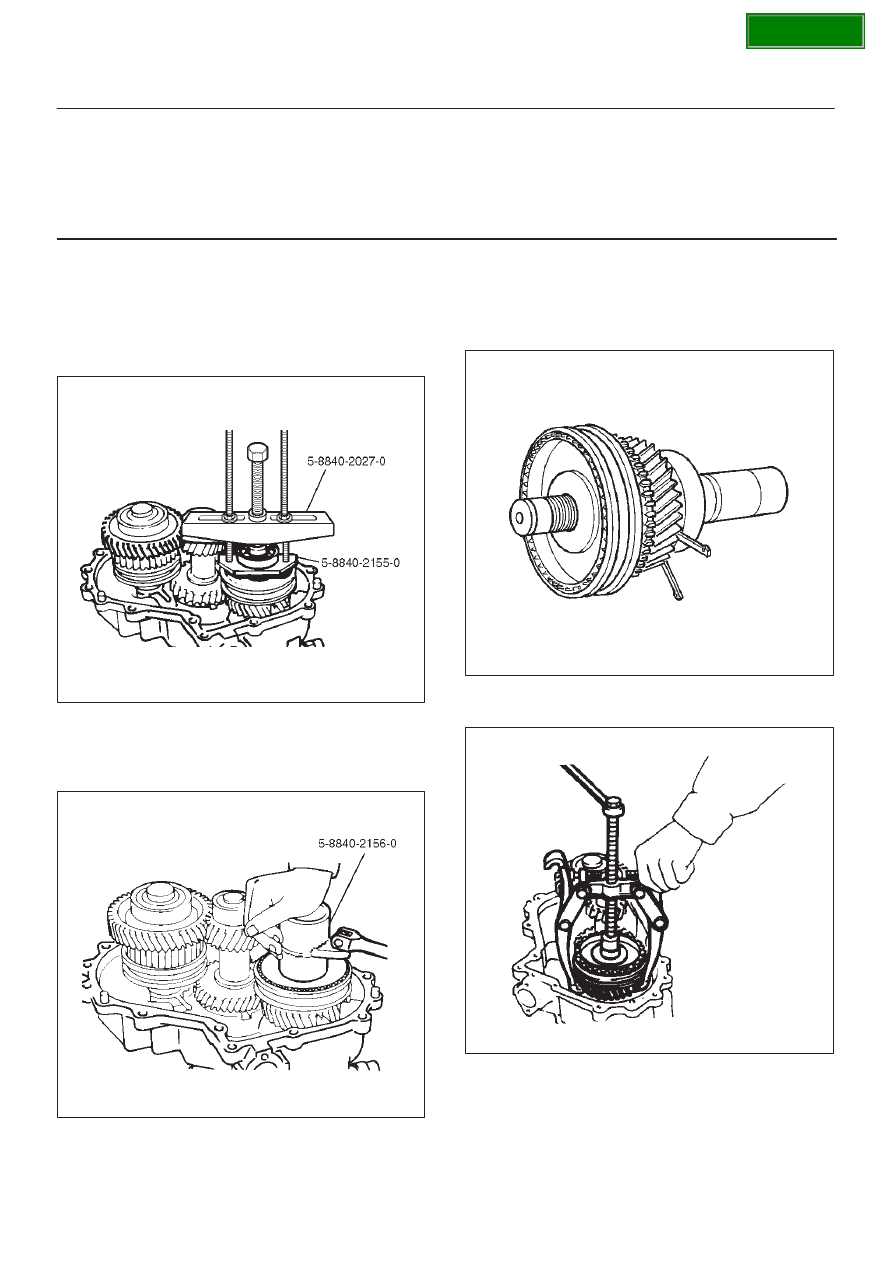

2. Use a bearing remover 5–8840–2155–0 and puller

5–8840–2027–0 to remove the ball bearing (2).

262RW069

3. Install the front companion flange temporarily.

4. Use the Companion flange holder 5–8840–0133–0

and lock nut wrench 5–8840–2156–0 to remove the

lock nut (3).

226RW190

5. Remove the front companion flange.

6. Remove snap ring (4). (A/T)

7. Remove the input shaft assembly (5) from the

transfer case (42). (A/T)

265RW001

8. Use the universal puller to remove the high–low

clutch hub and sleeve (6), and transfer input gear (7).

226RS070