Opel Frontera UE. Manual - part 26

1A–76

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

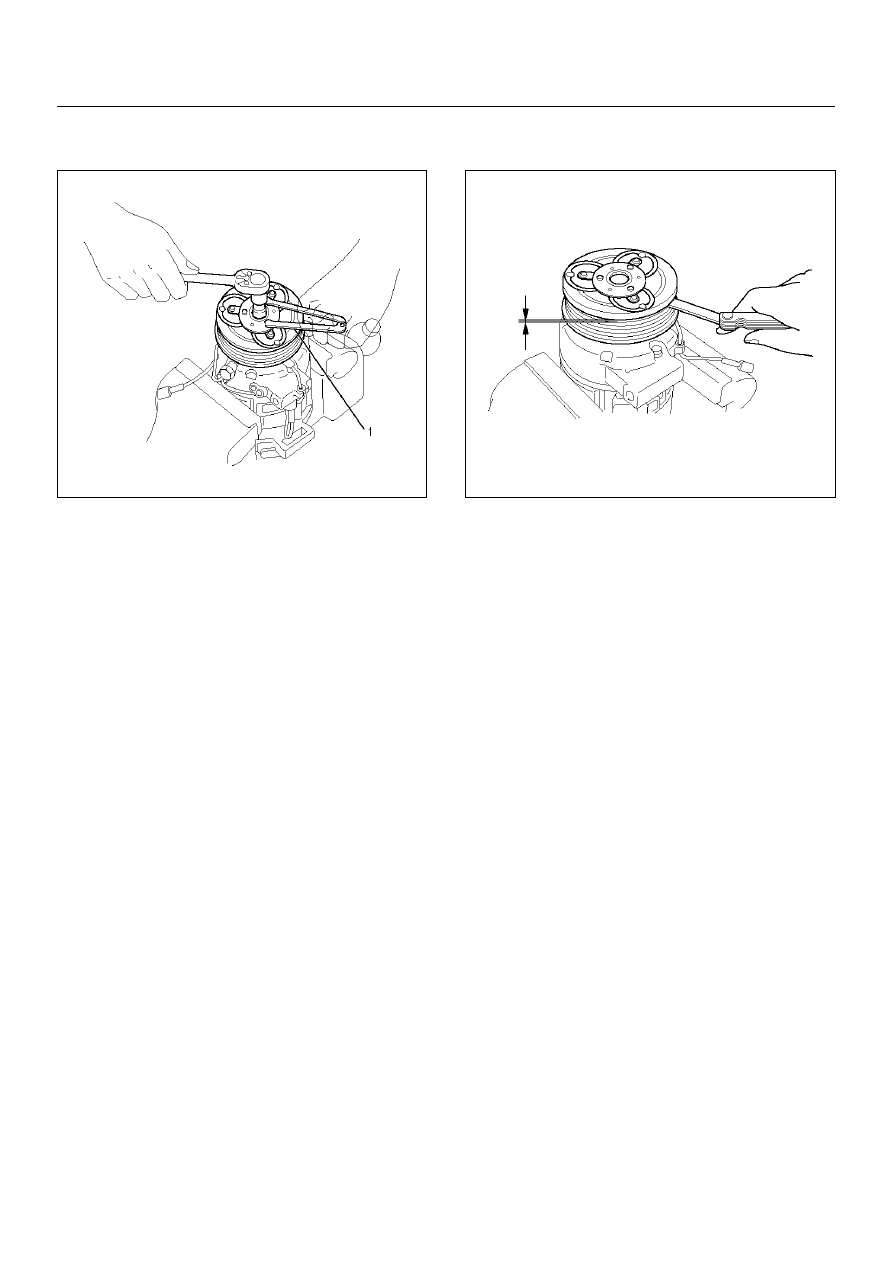

7. Install drive plate bolt by using drive plate holder

J-33939 (1) to prevent the drive plate from rotating.

901RX055

• Tighten the drive plate bolt to the specified

torque.

Torque: 13 N·m (113 lb in)

• After tightening the drive plate bolt, check to be

sure the pulley rotates smoothly.

• Check to be sure that the clutch clearance is

between 0.3-0.6 mm (0.01-0.02 in.)

871RX014

• If necessary, install adjusting shim(s).

• Adjusting shims are available in the following

thickness.

Thickness

• 0.1 mm (0.0039 in.)

• 0.3 mm (0.0118 in.)

• 0.5 mm (0.0197 in.)