Opel Frontera UE. Manual - part 24

1A–68

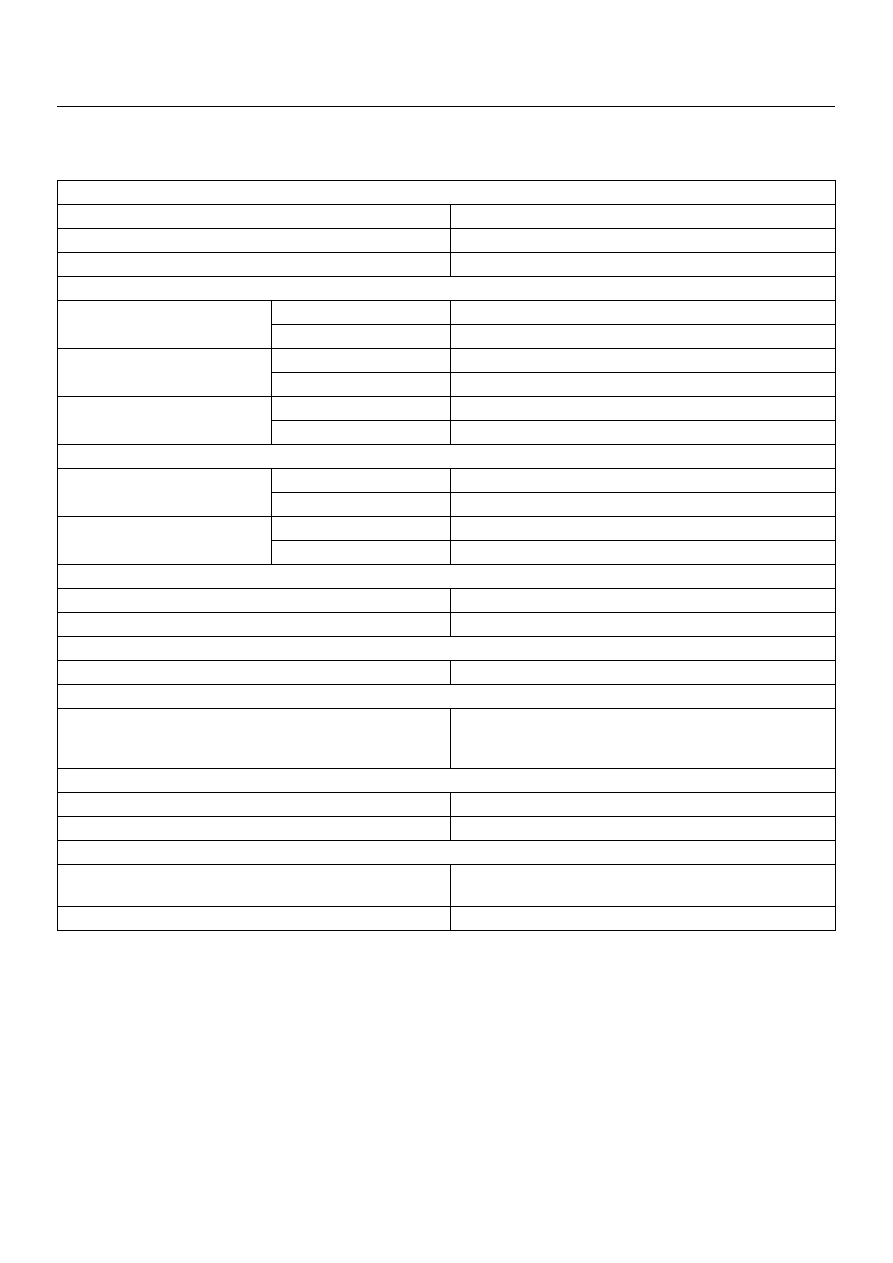

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

Main Data And Specifications

General Specifications

Heater Unit

Temperature control

Reheat air mix system

Capacity

3,700 Kcal./hr.

Air flow

280 m

3

/h

HEATER CORE

Type

AUTO A/C

Plate and corrugate-fin type

MANU A/C

Fin and tube type

Element dimension

MANU A/C

161 mm (6.3)

×

163 mm (6.4 in.)

×

45 mm (1.8 in.)

AUTO A/C

171 mm (6.7)

×

161 mm (6.3 in.)

×

25 mm (1 in.)

Radiating area

MANU A/C

Approx. 2.1 m

2

AUTO A/C

Approx. 1.3 m

2

EVAPORATOR ASSEMBLY

Capacity

AUTO A/C

4,100 Kcal./hr.

MANU A/C

4,200 Kcal./hr.

Air flow

AUTO A/C

430 m

3

/hr

MANU A/C

470 m

3

/hr

EVAPORATOR CORE

Type

Al-laminate louver fin type

Element dimension

235 mm (9.3 in.)

×

224 mm (8.8 in.)

×

60 mm (2.4 in.)

EXPANSION VALVE

Type

Internal pressure equalizer type

THERMOSTAT SWITCH

Type

Electronic thermostat

OFF: Below 0.5

±

0.5

°

C (32.9

±

0.9

°

F)

ON: Above 4.5

±

0.5

°

C (40.1

±

0.9

°

F)

CONDENSER

Type

Parallel flow type

Radiation performance

9,400 Kcal./hr

RECEIVER/DRIER

Type

Assembly includes sight glass with dual (triple) pressure

switch (V6) or pressure sensor (L14)

Internal volume

300 cc (10 fl.oz.)