Nissan Frontier D40. Manual - part 702

GI-32

< FEATURES OF NEW MODEL >

IDENTIFICATION INFORMATION

*1: Without roof rack

*2: With roof rack

Wheels & Tires

INFOID:0000000005272989

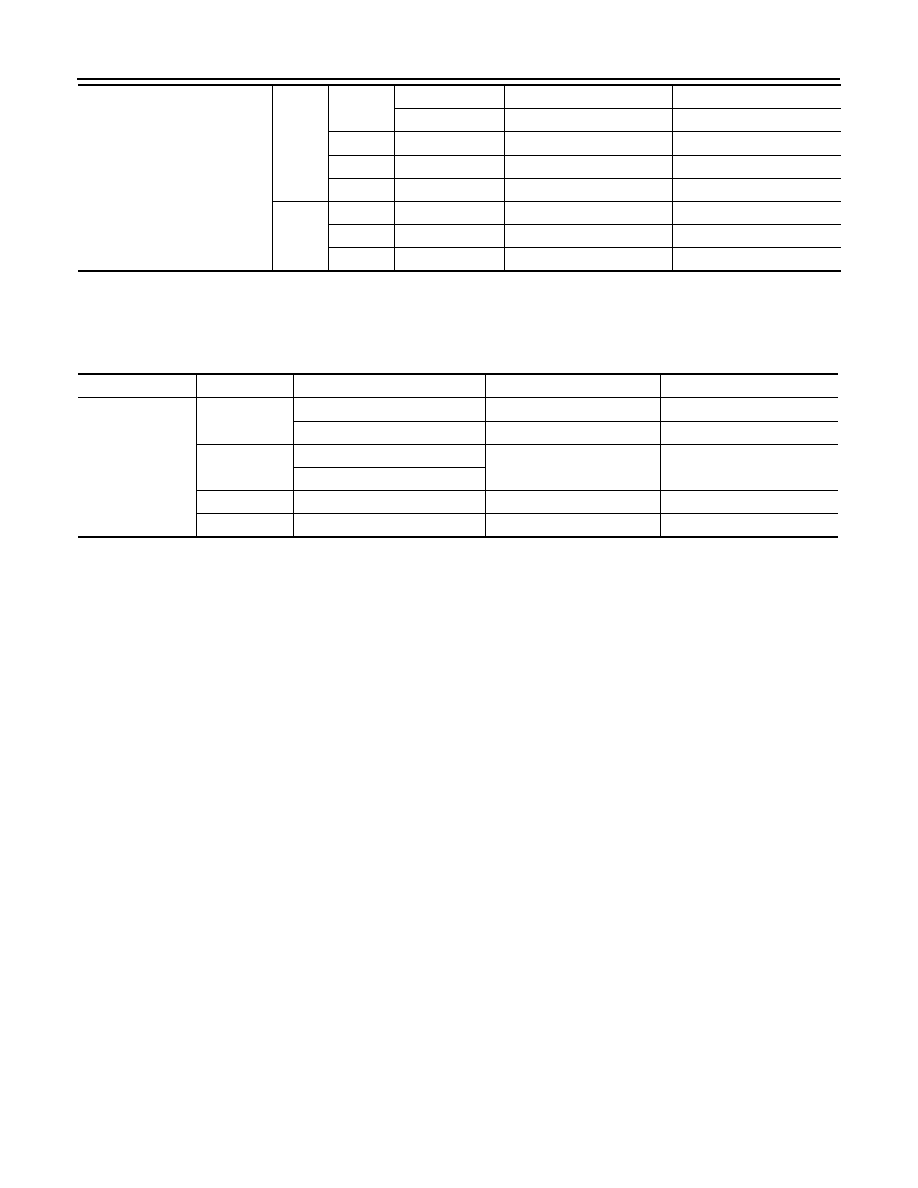

Minimum Running Ground

Clearance (with standard tires)

King

Cab

XE

235/75R15

193.4 (7.6)

—

265/70R16

218.2 (8.6)

226.1 (8.9)

SE

265/70R16

218.2 (8.6)

226.1 (8.9)

Pro-4X

265/75R16

218.2 (8.6)

226.1 (8.9)

LE

265/65R18

218.2 (8.6)

226.1 (8.9)

Crew

Cab

SE

265/70R16

218.2 (8.6)

226.1 (8.9)

Pro-4X

265/75R16

218.2 (8.6)

226.1 (8.9)

LE

265/65R18

218.2 (8.6)

226.1 (8.9)

Drive Type

Grade

Road wheel

Tire

Spare tire size

All

XE

15 X 7J Styled Steel

P235/75R15

P235/75R15

16 X 7J Designed Steel

P265/70R16

P265/70R16

SE

16 X 7J Designed Steel

P265/70R16

P265/70R16

16 X 7J Aluminum Alloy

Pro-4X

16 X 7J Aluminum Alloy

P265/75R16

P265/75R16

LE

18 X 8J Aluminum Alloy

P265/60R18

P265/60R18