Nissan Frontier D40. Manual - part 690

KNUCKLE

FSU-19

< REMOVAL AND INSTALLATION >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

7.

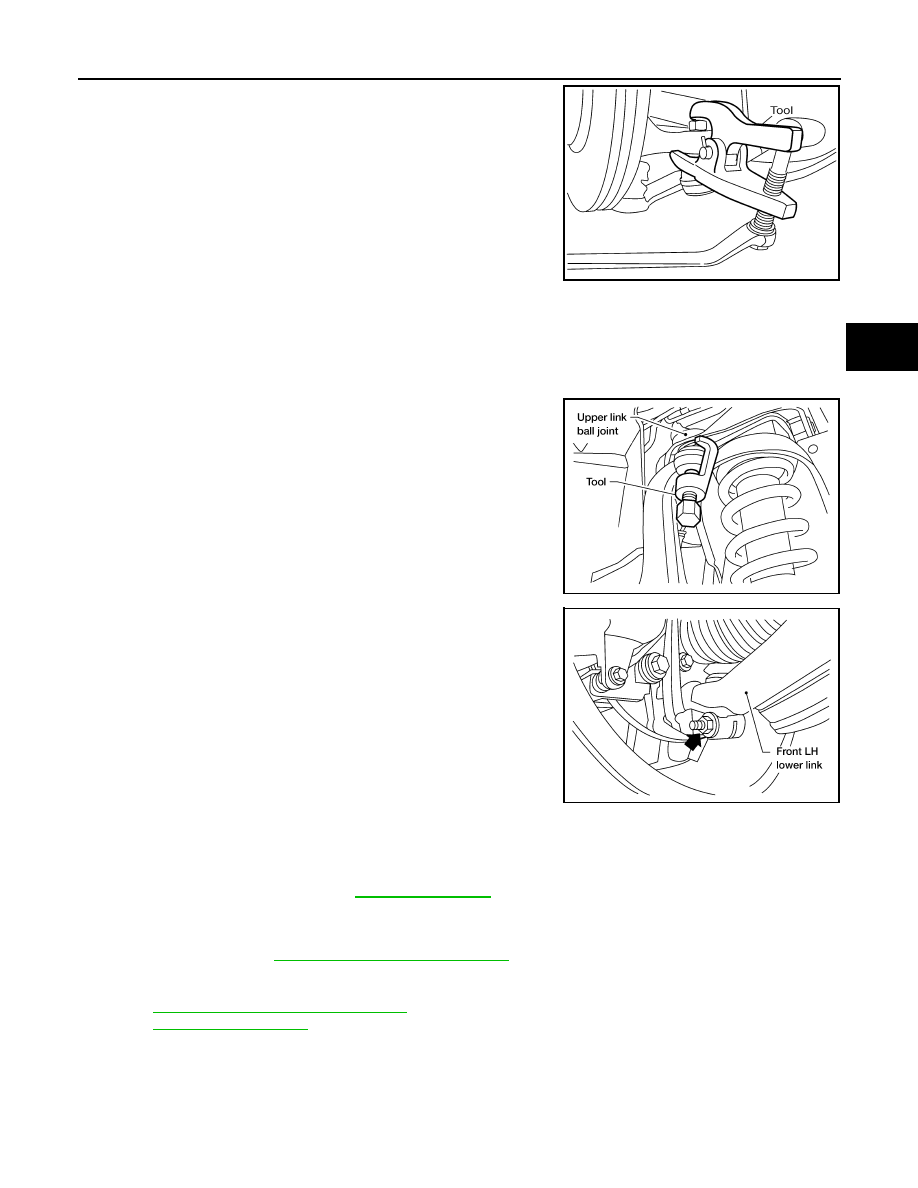

Disconnect steering outer socket from steering knuckle using

Tool. Be careful not to damage ball joint boot.

CAUTION:

To prevent damage to threads and to prevent Tool from

coming off suddenly, temporarily tighten nut.

8.

Remove wheel hub and bearing assembly bolts using power tool.

9.

Remove splash guard and wheel hub and bearing assembly from steering knuckle.

CAUTION:

Do not pull on wheel sensor harness.

10. Remove cotter pin and nut from upper link ball joint.

11. Separate upper link ball joint from steering knuckle using Tool.

12. Remove pinch bolt from steering knuckle using power tool, then

separate lower link ball joint from steering knuckle.

13. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to

.

INSTALLATION

Installation is in the reverse order of removal.

• For 4WD models, refer to

FAX-6, "Removal and Installation"

for drive shaft lock nut tightening torque.

CAUTION:

Always replace drive shaft lock nut and cotter pin.

• Refer to

ST-26, "Disassembly and Assembly"

for outer socket nut tightening torque.

• Refer to

for front suspension tightening torques.

Tool number

: HT72520000 (J-25730-A)

WGIA0130E

Tool number

: ST29020001 (J-24319-01)

WEIA0119E

LEIA0097E