Nissan Frontier D40. Manual - part 625

EM-232

< DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

ENGINE UNIT

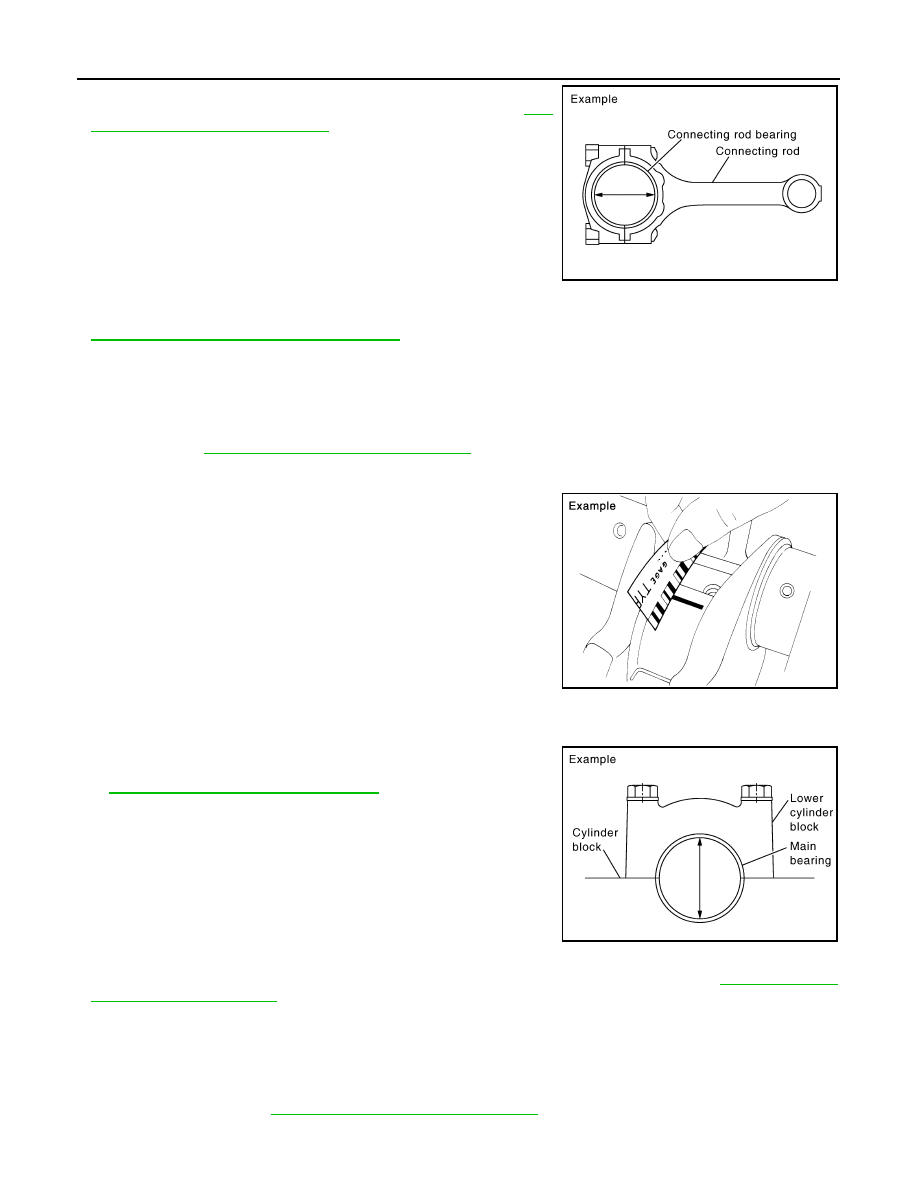

• Install connecting rod bearings to connecting rod and cap, and

tighten connecting rod bolts to the specified torque. Refer to

215, "Disassembly and Assembly"

for the tightening procedure.

• Measure the inner diameter of connecting rod bearing with inside

micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter) –

(Crankshaft pin journal diameter)

• If the calculated value exceeds the limit, select proper connecting rod bearing according to connecting rod

big end diameter and crankshaft pin journal diameter to obtain the specified bearing oil clearance. Refer to

EM-237, "How to Select Piston and Bearing"

Method of Using Plastigage

• Remove oil and dust on crankshaft pin journal and the surfaces of each bearing completely.

• Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install connecting rod bearings to connecting rod and cap, and tighten connecting rod bolts to the specified

EM-215, "Disassembly and Assembly"

for the tightening procedure.

CAUTION:

Do not rotate crankshaft.

• Remove connecting rod bearing cap and bearing, and using scale

on plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

• Install main bearings to cylinder block and lower cylinder block,

and tighten lower cylinder block bolts to the specified torque. Refer

to

EM-215, "Disassembly and Assembly"

for the tightening proce-

dure.

• Measure the inner diameter of main bearing with bore gauge.

(Bearing clearance) = (Main bearing inner diameter) – (Crankshaft

main journal diameter)

• If the calculated value exceeds the limit, select proper main bearing according to main bearing inner diame-

ter and crankshaft main journal diameter to obtain specified bearing oil clearance. Refer to

.

Method of Using Plastigage

• Remove engine oil and dust on crankshaft main journal and the surfaces of each bearing completely.

• Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install main bearings to cylinder block and lower cylinder block, and tighten lower cylinder block bolts to the

specified torque. Refer to

EM-215, "Disassembly and Assembly"

CAUTION:

Standard

: 0.034 - 0.059 mm (0.0013 - 0.0023 in) (actu-

al clearance)

Limit

: 0.070 mm (0.0028 in)

PBIC1642E

PBIC1149E

Standard

: 0.035 - 0.045 mm (0.0014 - 0.0018 in)

(actual clearance)

Limit

: 0.065 mm (0.0026 in)

PBIC2204E