Nissan Frontier D40. Manual - part 607

EM-160

< ON-VEHICLE REPAIR >

[VQ40DE]

FUEL INJECTOR AND FUEL TUBE

4.

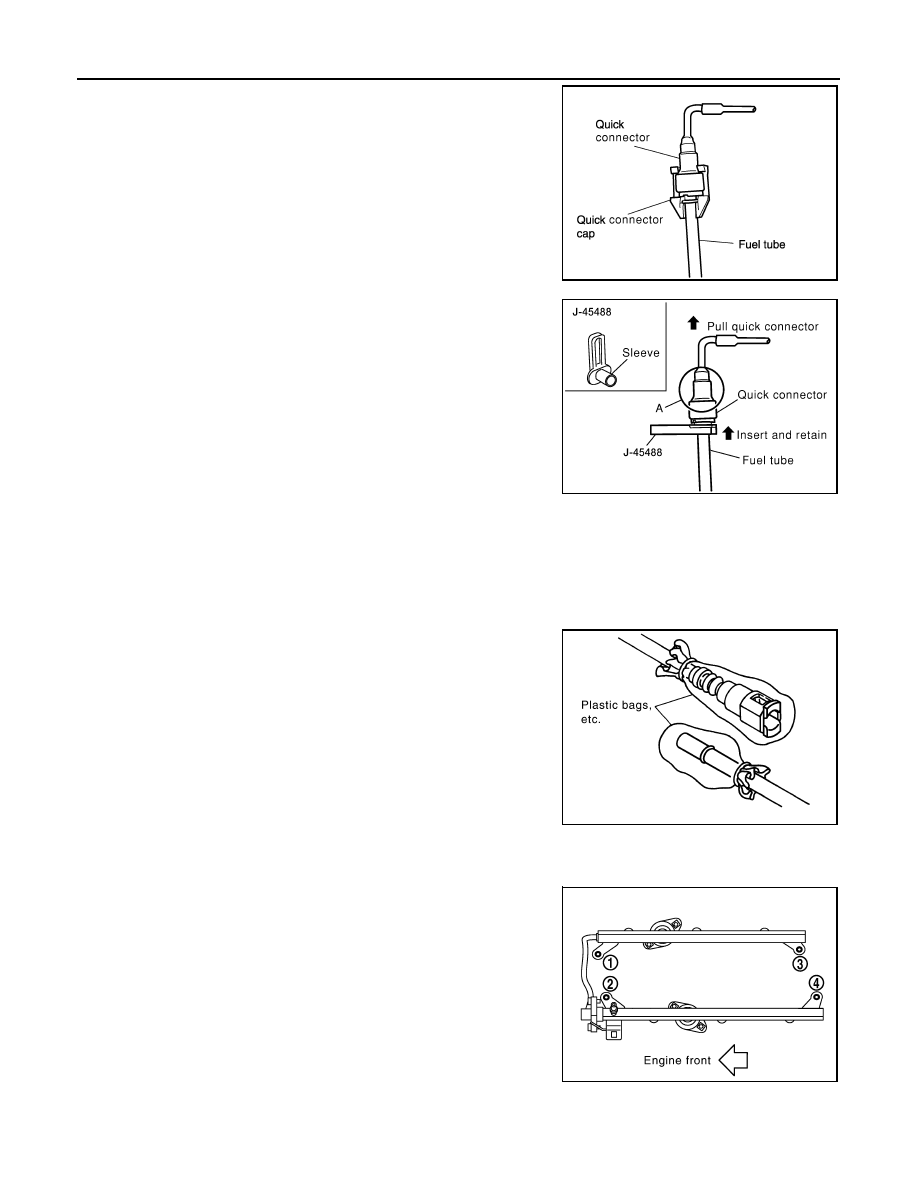

Disconnect the fuel quick connector on the engine side.

a.

Remove quick connector cap.

b.

With the sleeve side of Tool facing quick connector, install Tool

onto fuel tube.

c.

Insert Tool into quick connector until sleeve contacts and goes

no further. Hold the Tool on that position.

CAUTION:

Inserting the Tool hard will not disconnect quick connector.

Hold Tool where it contacts and goes no further.

d.

Pull the quick connector straight out from the fuel tube.

CAUTION:

• Pull quick connector holding it at the (A) position, as shown.

• Do not pull with lateral force applied. O-ring inside quick connector may be damaged.

• Prepare container and cloth beforehand as fuel will leak out.

• Avoid fire and sparks.

• Do not expose parts to battery electrolyte or other acids.

• Do not bend or twist connection between quick connector and fuel feed hose during removal

and installation.

• Be sure to cover openings of disconnected pipes with

plug or plastic bag to avoid fuel leakage and entry of for-

eign materials.

5.

Remove PCV hose between rocker covers (right and left banks).

6.

Disconnect harness connector from fuel injector.

7.

Loosen bolts in reverse order as shown, and remove fuel tube

and fuel injector assembly.

CAUTION:

Do not tilt it, or remaining fuel in pipes may flow out from

pipes.

8.

Remove bolts which connects fuel tube (RH) and fuel tube (LH).

LBIA0090E

Tool number

:

—

(J-45488)

WBIA0295E

PBIC1899E

PBIC2902E